FEATURES

- Strong, Light Weight, Low Cost

Superior to plastic circular connectors and less costly than metal connectors. Trident’s metal bayonet coupling nut and locking mechanism provide strength and life comparable to an all metal connector. Bodies are of durable UL94V0 thermoplastic with high strength nickel plated metal coupling nuts and bayonet ring. Molded rubber and silicone seals guarantee water-tightness. - Attractive Appearance

Nice enough for front panel mounting. - Submersible or Waterjet-proof Versions

Neptune uses a rear individual wire sealing grommet and is fully submersible to IP67. Ringlock is protected against submersion to IP67 using gland seal cable clamp. - Wide Temperature Range

Trident will operate in temperatures from -55ºC to +120ºC (-67º to +248ºF) under conditions of high humidity, severe vibration, ice, and mud. - Wide Range of Wire Gauges and Current Carrying Capability

Up to 30 amps per contact with wire sizes from 28 AWG up to 12 AWG wire. New TNM 700 volt 40 amp power for up to 8 AWG. - Standard and Reverse Connector Housings

In the Trident STANDARD configuration, the receptacles use socket contacts and the plugs use pin contacts. A REVERSED version is also available for safety and/or polarization. Standard and reversed connectors will not intermate. ‘Keying Pins’ are also available to polarize connectors with the same orientation and layout used on the same panel to prevent mis-mating. - Wide Range of Contact Styles

Contacts are available in crimp, PC, co-ax, wire wrap or first make/last break for ground connections. - Field Serviceable

The use of removable crimp contacts allows connections to be changed or modified in the field if necessary. Contacts are copper alloy with a range of gold or tin platings. - Agency Approvals

• UL and CSA (Trident Ringlock)

• IP67 Submersible

MATERIALS & FINISHES

ELECTRICAL DATA

MECHANICAL

Contact Retention:

Force (Min.)

Contact

Lbs.

Newtons

Machined

25

110

Stamped

15

65

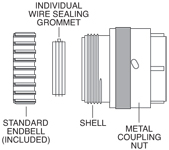

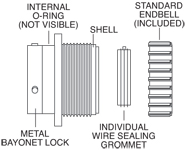

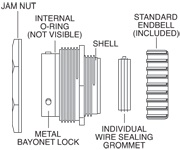

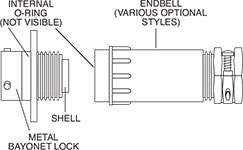

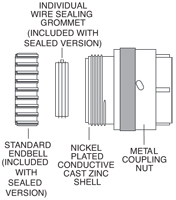

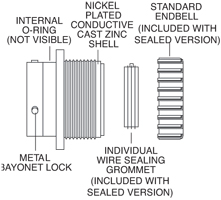

EXPLODED VIEW

Neptune

Plug

Flanged Receptacle

Jam Nut Receptacle

Ringlock

Plug

Flanged Receptacle

TNM

Plug

Flanged Receptacle

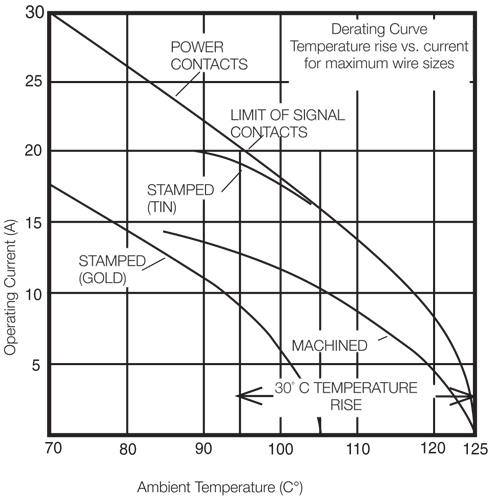

CURRENT RATING

Curves apply to single contacts in isolation. Use of smaller wire gauges or more than one contact in a connector requires derating.

Contact us for additional derating information.

STEP 1.

Determine number of circuits required per connector (4 to 48). Note that some Neptune layouts (shaded rows) have a mixture of power and signal contacts.

STEP 2.

Choose Trident Ringlock (waterjet proof) or Neptune (submersible). Neptune part numbers are shaded in chart.

STEP 3.

Select connector sex: STANDARD or REVERSED. Standard plugs have pin contacts, receptacles have sockets. Reversed plugs have socket contacts, receptacles have pins.

STEP 4.

Choose shell style: PLUG, FLANGED RECEPTACLE, or JAM NUT.

STEP 5.

Find part number on chart (remember, shaded part numbers are NEPTUNE).

STEP 6.

Select endbell, if needed. Neptune comes with low profile wire seal endbell; however, all endbells shown can be optionally used with Neptune connectors.

STEP 7.

Choose dust cap, if required.

STEP 8.

Select contacts and tooling below.

STEP 1.

Choose stamped or machined contacts.

STEP 2.

Choose contact type: crimp, PC, Power, first make/last break.

STEP 3.

Find your desired wire gauge in COLUMN 2.

STEP 4.

Choose contact plating in COLUMN 3.

STEP 5.

Select part number from COLUMNS 4, 5, 6, or 7.

STEP 6.

Select wire hole filler plugs (if needed) from COLUMN 10. Hole filler plugs are for Neptune version only (gray shaded connectors). Hole fillers are only used to re-seal unused grommet cavities that were punched out, but will not be filled with a wire.

STEP 7.

Select Keying pins (if needed) from COLUMN 11.

STEP 8.

Choose proper crimp tool for your contact from COLUMNS 12 thru 14.

STEP 9.

Choose proper extraction tool from COLUMN 15 (insertion tool not needed).

STEP 10.

Wire strip lengths and insulation dimensions are in COLUMNS 8 and 9.

TNM CONNECTORS

TNM 700 Volt Power Connector System

Shell Size 161

The TNM range of connectors is an extension of the long established Neptune and Trident Ringlock connector series but with the advantage of a number of additional features. These include RF shielding and moisture sealing to IP67.

The connectors feature strong nickel-plated zinc alloy shells with a metal coupling ring for high reliability and durability. When used with the new low cost shielded endbells the connector system provides RF shielding from cable to equipment or cable to cable that satisfy EMC requirements.

The signal contacts used are from the standard Trident contact range (See pages 58-59). The recommended contacts are the stamped and formed Two Part, available with either tin or gold plated finish. If a higher performance is required the Trident Three Part machined contacts can be used. All signal contacts have a current rating of 13 Amps and wires with conductors 14 - 28AWG (2.50 mm2 -.08 mm2) can be accommodated. Note if more than 4 contacts per connector are designed to run at, or near, their full rated current for sustained periods, a derating factor must be applied. For further details please call 800-523-0727.

Mating face of plug for standard sex is shown. Reverse sex have mirror image cavity identification.

Power Contact TNM 700 Volts Only

Type

Sockets

Pins

Amp Max.

Solder

DM53744-21

DM53745-28

40

Crimp 8-10Awg

DM130341-21

DM130338-28

40

Crimp 12-14Awg

DM130342-21

DM130339-28

20

Crimp 16-18Awg

DM130343-21

DM130340-28

10