MS3057-A

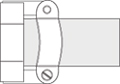

Standard MS3057 cable clamps have dual-clamping action to provide a balanced, positive hold on the wires and greatly reduce moisture transmission. This cable clamp accepts MS3420 bushings. MS3420 bushings can be nested to reduce the inside diameter to more closely match the diameter of the cable or wire bundle.

Standard Clamp

Standard Clamp and Telescopic Bushing

Shell Size

Thread Class 2B

Low-Cost Cast Zinc

Aluminum W/ Brass Screws

Aluminum W/ Stainless Steel Screws

Maximum Cable Diameter Inch (MM)

Zinc With

Bushing

Low-Cost Bushing Included

Bushing ID Inch (MM)

10SL

5/8-24UNEF

97-3057-1004**

MS3057-4A

M85049/41-4A

0.312 (7.92)

97-3057-1004-1

MS3420-4

0.220 (5.6)

14S

3/4-20UNEF

97-3057-1007**

MS3057-6A

M85049/41-6A

0.438 (11.10)

97-3057-1007-1

MS3420-6

0.312 (7.9)

16/16S

7/8-20UNEF

97-3057-1008**

MS3057-8A

M85049/41-8A

0.562 (14.27)

97-3057-1008-1

MS3420-8

0.437 (11.1)

18

1-20UNEF

97-3057-1010**

MS3057-10A

M85049/41-10A

0.625 (15.88)

97-3057-1010-1

MS3420-10

0.562 (14.3)

20/22

1 3/16-18UNEF

97-3057-1012**

MS3057-12A

M85049/41-12A

0.750

(19.0)

97-3057-1012-1

MS3420-12

0.625 (15.9)

24/28

1 7/16-18UNEF

97-3057-1016**

MS3057-16A

M85049/41-16A

0.938 (23.80)

97-3057-1016-1

MS3420-16, -12

0.625 (15.9)

32

1 3/4-18UNS

97-3057-1020**

MS3057-20A

M85049/41-20A

1.250 (31.75)

97-3057-1020-1

MS3420-20, -16

0.750 (19.0)

36

2-18UNS

97-3057-1024**

MS3057-24A

M85049/41-24A

1.375 (34.92)

97-3057-1024-1

MS3420-24, -20

0.937 (23.8)

40

2 1/4-16UNS

-

MS3057-28A

M85049/41-28A

1.625 (41.28)

-

-

-

** Other platings are available.

All dimensions in inches (millimeters in parentheses)

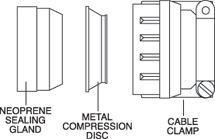

MS3057-C

Standard MS3057-C waterproof cable clamp with mechanical strain relief for use with styles F, L and T endbells. Internal neoprene gland and compression ring will seal a broad range of round cable diameters as listed below. For reduction of cable diameters, order the appropriate MS3420A bushing in table.

Wire Diameter

Inches (MM)

Optional Bushings

Shell Size

Part Number

Max.

Min.

Part Number

Max. Wire Dia.

Inches (MM)

10SL

MS3057-4C

0.312 (7.93)

0.188 (4.80)

MS3420-4A

0.219 (5.56)

14S

MS3057-6C

0.438 (11.12)

0.281 (7.10)

MS3420-6A

MS3420-4A

0.312 (7.93)

0.219 (5.56)

16/16S

MS3057-8C

0.530 (13.48)

0.312 (7.90)

MS3420-8A

MS3420-6A

0.438 (11.10)

0.312 (7.93)

18

MS3057-10C

0.625 (15.87)

0.375 (9.50)

MS3420-10A

MS3420-6A

0.438 (11.10)

0.312 (7.93)

20/22

MS3057-12C

0.750 (19.00)

0.500 (12.70)

MS3420-12A

MS3420-8A

0.540 (13.74)

0.438 (11.10)

24/28

MS3057-16C

0.940 (23.80)

0.625 (15.90)

MS3420-16A

MS3420-12A

MS3420-8A

0.750 (19.00)

0.540 (13.74)

0.438 (11.10)

32

MS3057-20C

1.25 (31.75)

0.921 (23.40)

MS3420-20A

MS3420-16A

MS3420-12A

0.938 (23.80)

0.750 (19.00)

0.540 (13.74)

36

MS3057-24C

1.38 (35.00)

1.00 (25.40)

MS3420-24A

MS3420-18A

MS3420-16A

1.12 (28.50)

0.938 (23.80)

0.750 (19.00)

40

MS3057-28C

1.62 (41.25)

1.25 (31.80)

MS3420-28A

MS3420-20A

MS3420-16A

1.125 (31.75)

0.940 (23.80)

0.750 (19.00)

All dimensions in inches (millimeters in parentheses)

MS3420

For use with style-A cable clamps and AIT/MS style-E/F endbells to resist dust, dirt and oil. Bushings can be nested, one inside the other, to reduce the inside diameter and form a better seal against the cable jacket. Each bushing will accept the next smallest bushing.

Shell Size

First Bushing Part Number

Inside Diameter

2nd Nested Bushing

Inside Diameter

Fits in Cable Clamp

10SL

MS3420-4

.220 (5.59)

NONE

-

MS3057-4A

14S

MS3420-6

.312 (7.92)

NONE

-

MS3057-6A

16S

MS3420-8

.437 (11.10)

NONE

-

MS3057-8A

16

MS3420-8

.437 (11.10)

NONE

-

MS3057-8A

18

MS3420-10

.562 (14.30)

NONE

-

MS3057-10A

20

MS3420-12

.625 (15.90)

NONE

-

MS3057-12A

22

MS3420-12

.625 (15.90)

NONE

-

MS3057-12A

24

MS3420-16

.750 (19.05)

MS3420-12

.625 (15.90)

MS3057-16A

28

MS3420-16

.750 (19.05)

MS3420-12

.625 (15.90)

MS3057-16A

32

MS3420-20

.937 (23.80)

MS3420-16

.750 (19.05)

MS3057-20A

36

MS3420-24

1.250 (31.75)

MS3420-20

.937 (23.80)

MS3057-24A

40

MS3420-28

1.375 (34.92)

MS3420-24

1.250 (31.75)

SE96-28A4

All dimensions in inches (millimeters in parentheses)

MS3420-A

For use with MS3057-C cable clamps (style-C) to reduce the wire sealing diameter. Bushings can be nested, one inside the other, to progressively reduce the inside diameter of the cable clamp. The column labeled “reduction bushings” shows the acceptable nesting options for each clamp.

9767

9767 waterproof cable clamp with mechanical strain relief. An internal neoprene gland seal bushing and compression washer will seal a broad range of round cable diameters, as listed below.

Max. Cable Outside Diameter

Min. Cable Outside Diameter

Shell Size

Cable Clamp

Part Number

Inches

MM

Inches

MM

Thread Class 2B

10SL

9767-12-4

0.219

5.55

0.020

0.51

5/8-24 UNEF

14S

9767-14-4

0.219

5.55

0.020

0.51

3/4-20 UNEF

14S

9767-14-6

0.344

8.73

0.176

4.47

3/4-20 UNEF

16S/16

9767-16-4

0.219

5.55

0.020

0.51

3/4-20 UNEF

16S/16

9767-16-6

0.344

8.73

0.176

4.47

3/4-20 UNEF

16S/16

9767-16-8

0.438

11.12

0.177

4.50

7/8-20 UNEF

18

9767-18-6

0.344

8.73

0.176

4.47

1-20 UNEF

18

9767-18-8

0.438

11.12

0.177

4.50

1-20 UNEF

18

9767-18-10

0.563

14.29

0.292

7.42

1-20 UNEF

20/22

9767-22-8

0.438

11.12

0.177

4.50

1-3/16-18 UNEF

20/22

9767-22-10

0.563

14.29

0.292

7.42

1-3/16-18 UNEF

20/22

9767-22-12

0.688

17.46

0.370

9.40

1-3/16-18 UNEF

24/28

9767-28-10

0.563

14.29

0.292

7.42

1-7/16-18 UNEF

24/28

9767-28-12

0.688

17.46

0.370

9.40

1-7/16-18 UNEF

24/28

9767-28-16

0.844

21.43

0.536

13.61

1-7/16-18 UNEF

32

9767-32-20

1.031

26.19

0.590

14.99

1-3/4-18 UNS

36

9767-36-16

0.844

21.43

0.536

13.61

2-18 UNS

GASKETS

Synthetic rubber gaskets are used to ensure a moisture-tight seal between a receptacle and the panel. Gaskets are available for front or rear-panel mounting of styles 0, 2, 20, 30 and TB connectors. Gasket thickness is approximately .031 inches (1 mm), for nonconductive and low-temperature types. Conductive shielding gaskets contain an embedded metal screen for EMI/RFI shielding in addition to moisture sealing. Gaskets are available for front or rear-panel mounting of styles 30 and TB connectors. Gasket thickness is .020 inches (.5 mm).

Front Mount

Rear Mount

Shell Size

Non-Conductive

Conductive

Low-Temperature

-67ºF (-55ºC)

Non-Conductive

10SL

10-040450-010

10-040450-10S

10-036675-010

10-580649-011

14S

10-040450-014

10-040450-14S

10-036675-014

10-580649-014

16S

10-040450-016

10-040450-16S

10-036675-016

10-580649-016

16

10-040450-016

10-040450-16S

10-036675-016

10-580649-016

18

10-040450-018

10-040450-18S

10-036675-018

10-580649-018

20

10-040450-020

10-040450-20S

10-036675-020

10-580649-020

22

10-040450-022

10-040450-22S

10-036675-022

10-580649-022

24

10-040450-024

10-040450-24S

10-036675-024

10-580649-024

28

10-040450-028

10-040450-28S

10-036675-028

10-580649-028

32

10-040450-032

10-040450-32S

10-036675-032

10-580649-032

36

10-040450-036

10-040450-36S

10-036675-036

10-580649-036

40

10-040450-040

10-040450-40S

10-036675-040

10-580649-040

METAL DUST CAPS

Metal dust caps are used to protect the contacts when the connectors are left unmated. Dust caps come with metal chain lanyards. Dummy Receptacles are for front or rear-panel mounting. AIB/GT Series connectors have bayonet ramps. The center of the connector is closed. Dummy receptacles mount on the same centers and have the same outside dimensions as a STYLE 2 receptacle. A version with a clearance hole through the middle of the connector is also available. Contact us for ordering information.

Dust Caps

Plug Cap

Receptacle

Dummy Receptacles

Plug Seal Ring

Shell Size

10SL

10-580903-11*

10-580902-11*

10-580595-11*

10-564843-101

14S

10-580903-14*

10-580902-14*

10-580595-14*

10-564843-141

16S

10-580903-16*

10-580902-16*

10-580595-16*

10-564843-161

16

10-580903-17*

10-580902-17*

10-580595-17*

10-564843-161

18

10-580903-18*

10-580902-18*

10-580595-18*

10-564843-181

20

10-580903-20*

10-580902-20*

10-580595-20*

10-564843-201

22

10-580903-22*

10-580902-22*

10-580595-22*

10-564843-221

24

10-580903-24*

10-580902-24*

10-580595-24*

10-564843-241

28

10-580903-28*

10-580902-28*

10-580595-28*

10-564843-281

32

10-580903-32*

10-580902-32*

10-580595-32*

10-564843-321

36

10-580903-36*

10-580902-36*

10-580595-36*

10-564843-161

40

10-580903-40*

10-580902-40*

10-580595-40*

10-564843-401

*Select code for plating:

Z = Black anodize

3 = Olive drab cadmium plate

9 = Olive drab cadmium nickel base

G = Electroless nickel

U = Green zinc

Y = Black alloy