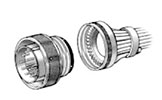

ITT Cannon PV Connectors (26482 Style Series II)

INTERMATEABLE WITH ALL 26482-STYLE SERIES II CONNECTORS

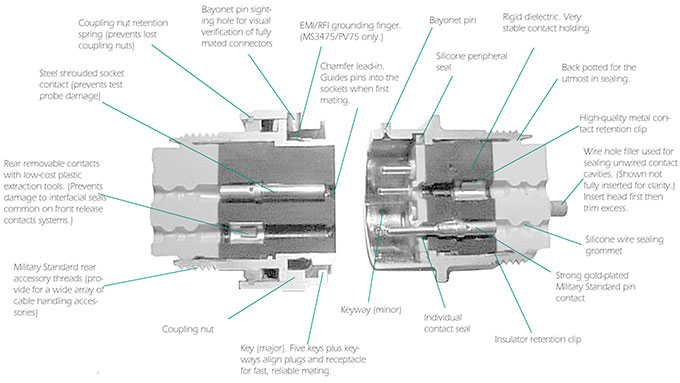

ITT Cannon PV series 26482-Style Series II connectors are excellent aircraft and aerospace connectors and are used in harsh environments where reliability is critical. These PV connectors have a quick-mating three-point bayonet coupling system and use ITT Cannon’s rugged LITTLE CAESAR® contact retention system. Unlike series I, 26482-Style Series II connectors are equipped with standard military rear threads, allowing for a broad range of back end options. ITT Cannon PV connectors are intermateable with Souriau connectors and all 26482-Style Series II connectors. For full details on ITT Cannon PV connectors, see the product specifications below.

|

FEATURESITT CANNON PV SERIES FEATURES

MATERIALS & FINISHESITT CANNON PV SERIES MATERIALS & FINISHES

Shell High-grade aluminum alloy per QQ-A-367, QQ-A-591 or QQ-A-225

Jam Nut Aluminum alloy per QQ-A-225

Coupling Nut High-grade aluminum alloy per QQ-A-591

Plating Electroless nickel per MIL-C-26074 class 3 or 4 grade B, or Olive drab chromate over cadmium over nickel per QQ-P-416

Bayonet Pins Passivated stainless steel per QQ-S-763

Contacts Copper Alloy

Contact Plating Gold plated per MIL-G-45204 50 microinches

Insulator Rigid plastic dielectric

Grommet & Seals Silicone-based elastomer

ELECTRICAL DATAITT CANNON PV SERIES ELECTRICAL DATA

Working & Test Voltage Working Test Service Rating At Seal Level 70,000 feet altitude At Seal Level 70,000 feet Altitude I 600 300 1,500 375 II 1,000 450 2,300 500 Current Rating Wire Size Contact Max. Current for test Potential Drop Millivolt 24 20 3 20 20 7.5 20 16 7.5 16 16 13 14 12 17 12 12 23 Wire Range Sizes 24 AWG to 12 AWG

Insulation Resistance 5,000 Megohms minimum at 25°C; (77°F)

500 Megohm minimum at 200°C (392°F) Class L and 175°C (347°F) Class W MECHANICALITT CANNON PV SERIES MECHANICAL

Operating Temperature All platings: -55°C to +200°C; (-67°F to +392°F)

Wire Sealing Range Contact Size Wire Sealing Range Min. inch (mm) Wire Sealing Range Max. inch (mm) 20 .040 (1.02) .083 (2.11) 16 .053 (1.35) .103 (2.62) 12 .097 (2.46) .158 (4.01) Insulation Strip Length Contact Size Wire Size AWG Strip Length Inch (mm) 20 20-24 .188 (4.76) 16 16-20 .281 (7.14) 12 12-14 .281 (7.14) Mating Life 500 cycles minimum, 250 cycle minimum for shielded plug

Salt Spray Class W 48 hours unmated; 452 hours mated per MIL-STD-1344 method, 1001 per MIL-DTL-26482

Heat Class L, +200°C (+392°F); Class W +175°C (+347°F) for 1000 hours to MIL-STD-1344 Method 1005.1

Chemical Resistance Tested unmated according to MIL-DTL-26482 4.6.28 for hydraulic fluid, lubricating oil, deicing fluids, jet fuels, solvents and coolants

Vibration 10 to 2,000Hz (20g’s) 10 microseconds maximum discontinuity. To MIL-STD-1344 Method 2005 per MIL-DTL-26482

Shock 150g’s 6ms duration, three major axes. 10 microsecond maximum discontinuity

Contact Type Crimp, co-ax, twinax, thermocouple, printed circuit board, and fiber optic

Number of Circuits 3 to 61

Contact Insertion & Extraction Insertion from rear of connector with simple plastic or high-quality metal hand tool. Extraction from rear with plastic or high-quality metal hand tools

Content Retention Per MIL-STD-1344A method 2007 per MIL-DTL-26482

Contact Size Axial Load Pounds Min. 20 20 16 25 12 30 Polarization Five keyway, three-point bayonet with optional rotational polarization

|

|

ITT CANNON PV SERIES APPLICATIONS

|

STEP 1: STYLEITT CANNON PV SERIES MILITARY SOLDER EXAMPLE

1 2 3 4 5 6 MS3470 L 24-61 P W -L/C SHELL STYLE FINISH LAYOUT CONTACT ROTATION MODIFIER ITT CANNON PV SERIES COMMERCIAL EXAMPLE

1 2 3 4 5 6 PV70 L 24-61 P W -L/C SHELL STYLE FINISH LAYOUT CONTACT ROTATION MODIFIER STEP 1: CHOOSE STYLE

** Not available in size 8 STEP 2: FINISHSTEP 2: CHOOSE FINISH

L = Electroless Nickel W = Olive Drab Chromate over Cadmium over Nickel 500 Hour Salt Spray STEP 3: LAYOUTSTEP 3: CHOOSE LAYOUT

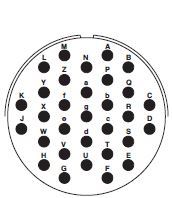

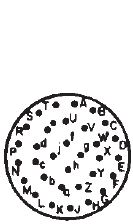

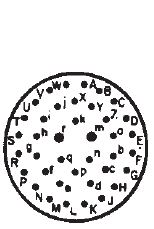

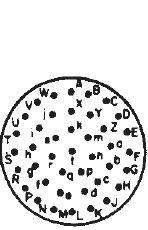

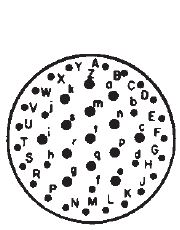

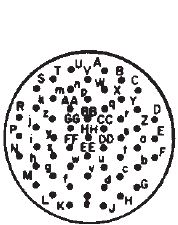

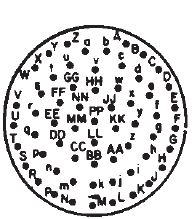

Layouts listed by Shell Size Rotations Layout Number Service Rating Total Number of Contacts 20 16 12 W X Y Z 8-33 I 3 3 90 - - - 8-98 I 3 3 - - - - 10-6 I 6 6 90 - - - 12-3 II 3 3 - - 180 - 12-8 I 8 8 90 112 203 292 12-10 I 10 10 60 155 270 295 14-4 I 4 4 45 - - - 14-5 II 5 5 40 92 184 273 14-12 I 12 8 4 43 90 - - 14-15 I 15 14 1 17 110 155 234 14-18 I 18 18 15 90 180 270 14-19 I 19 19 30 165 315 - 16-8 II 8 8 54 152 180 331 16-23 I 23 22 1 158 270 - - 16-26 I 26 26 60 - 275 338 18-8 I 8 8 180 - - - 18-11 II 11 11 62 119 241 340 18-32 I 32 32 85 138 222 265 20-16 II 16 16 238 318 333 347 20-39 I 39 37 2 63 144 252 333 20-41 I 41 41 45 126 225 - 22-21 II 21 21 16 135 175 349 22-41 I 41 27 14 39 135 264 - 22-55 I 55 55 30 142 226 314 24-19 II 19 19 30 165 315 - 24-31 I 31 31 90 225 255 - 24-61 I 61 61 90 180 270 324 Read Less LAYOUTS BY NUMBER OF CONTACTS

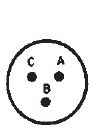

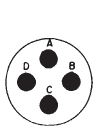

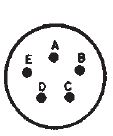

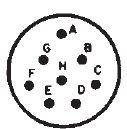

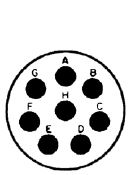

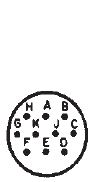

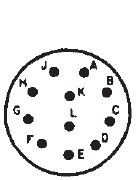

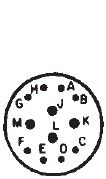

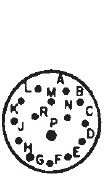

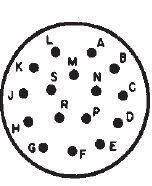

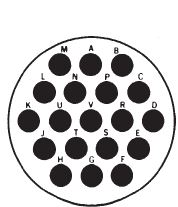

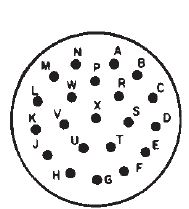

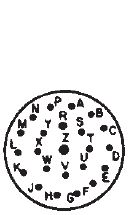

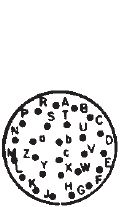

Drawing not to scale; mating-face view of pin insert shown (socket view is opposite).

Contacts 3 4 5 6 8

Shell Size/Layout 8-33 8-98* 12-3 14-4 14-5 10-6 12-8 16-8 # of Contacts 3-#20 3-#20 3-#16 4-#12 5-#16 6-#20 8-#20 8-#16 Service Rating I I II I II I I II Contacts 8 10 11 12 15 16 18

Shell Size/ Layout 18-8 12-10 18-11 14-12 14-15 20-16 14-18 # of Contacts 8-#12 10-#20 11-#16 8-#20; 4-#16 14-#20; 1-#16 16-#16 18-#20 Service Rating I I II I I II I Contacts 19 21 23 26 31

Shell Size/Layout 14-19 24-19 22-21 16-23 16-26 24-31 # of Contacts 19-#20 19-#12 21-#16 22-#20; 1-#16 26-#20 31-#16 Service Rating I II II I I I Contacts 32 29 41 55 61

Shell Size/Layout 18-32 20-39 20-41 22-41 22-55 24-61 # of Contacts 32-#20 37-#20; 2-#16 41-#20 27-#20; 14-#16 55-#20 61-#20 Service Rating I I I I I I *Layout available in MS3470 and MS3476 only Read Less STEP 4: CONTACTSTEP 4: CHOOSE CONTACT

P = Pin S = Socket A = Less Pin Contacts B = Less Socket Contacts STEP 6: MODIFIERSTEP 6: CHOOSE MODIFIER

-L/C = for use with standard contacts, but supplied without contacts, seal plugs or tools (PO must state Less Contacts) Note: L/C is not marked on part For other commercial modification, i.e., less tools, with PC contact or with endbell, contact us. |

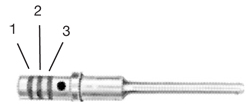

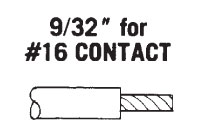

CONTACTSITT CANNON PV SERIES PINS

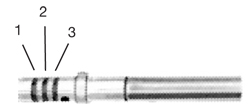

Color Wire Insulation Range Contact Wire Size Pin Contact 1 2 3 Wire Strip Min. Max. Wire Hole Filler Color 20 20, 22 & 24 M39029/4-110 Brown Brown Black 3/16 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16, 18 & 20 M39029/4-111 Brown Brown Brown 9/32 (7.14) .053 (1.35) .103 (2.62) MS27488-16-2 Blue 12 12 & 14 M39029/4-113 Brown Brown Orange 9/32 (7.14) .097 (2.46) .158 (4.01) MS27488-12-2 Yellow 20 Aluminel* 20, 22 & 24 030-1831-000 - - - 3/16 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 20 Chromel* 20, 22 & 24 030-1832-000 - - - 3/16 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 Fiber Optic* - MIL-T-29504/10 - - - - - - - - 12 Co-ax* - - - - - - - - - For Printed Circuit, Fiber Optic (MIL-T-29504/4 for size 16 contacts) or Thermocouple Contacts, contact us. ITT CANNON PV SERIES SOCKETS

Color Wire Insulation Range Contact Wire Size Socket Contact 1 2 3 Wire Strip Min. Max. Wire Hole Filler Color 20 20, 22 & 24 M39029/5-115 Brown Brown Green 3/16 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16, 18 & 20 M39029/5-116 Brown Brown Blue 9/32 (7.14) .053 (1.35) .103 (2.62) MS27488-16-2 Blue 12 12 & 14 M39029/5-118 Brown Brown Grey 9/32 (7.14) .097 (2.46) .158 (4.01) MS27488-12-2 Yellow 20 Aluminel* 20, 22 & 24 031-1013-000 - - - 3/16 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 20 Chromel* 20, 22 & 24 031-1014-000 - - - 3/16 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 Fiber Optic* - MIL-T-29504/11 - - - - - - - - 12 Co-ax* - - - - - - - - - For Printed Circuit, Fiber Optic (MIL-T-29504/5 for size 16 contacts) or Thermocouple Contacts, contact us. * Special - Contact us for information All dimensions in inches (millimeters in parentheses) unless otherwise stated. CONTACT TOOLSITT CANNON PV SERIES PIN & SOCKET CONTACT TOOLS

Metal Plastic Contact Hand Power Turret Use Insertion Extraction Tool Insertion/ Extraction Tool Insertion Extraction 20 M22520/1-01 CBT530 M22520/1-02 Red DAK83-20B DRK83-20B M81969/ Red White 16 M22520/1-01 CBT530 M22520/1-02 Blue DAK83-16B DRK83-16B M81969/ Blue White 12 M22520/1-01 CBT530 M22520/1-02 Yellow DAK83-12B DRK83-12B/p> M81969/ Yellow White 20 - - - - - - - - - 20 - - - - - - - - - 16 Fiber - - - - - - - - - 12 - - - - - - - - - * Special - Contact us for information |

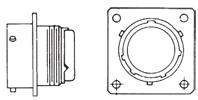

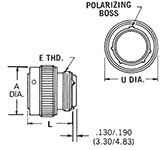

PLUGSITT CANNON PV SERIES PLUGS

MS3476/PV76 MS3475/PV75

Shell Size A Dia. Max. U Dia. Max. L Max. E Rear Thread UNEF-2A 8* .765 (19.43) .782 (19.86) 1.230 (31.24) 1/2-20 10 .840 (21.34) .926 (23.52) 1.230 (31.24) 5/8-24 12 .999 (25.37) 1.043 (26.49) 1.230 (31.24) 3/4-20 14 1.139 (28.93) 1.183 (30.05) 1.230 (31.24) 7/8-20 16 1.261 (32.03) 1.305 (33.15) 1.230 (31.24) 1-20 18 1.337 (33.96) 1.391 (35.33) 1.230 (31.24) 1-1/16-18 20 1.477 (37.52) 1.531 (38.89) 1.230 (31.24) 1-3/16-18 22 1.602 (40.69) 1.656 (42.06) 1.230 (31.24) 1-5/16-18 24 1.723 (43.76) 1.777 (45.14) 1.230 (31.24) 1-7/16-18 *MS3475/PV75 not available in size 8 RECEPTACLESITT CANNON PV SERIES FLANGED RECEPTACLES

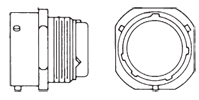

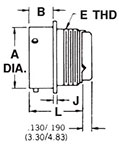

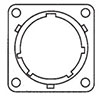

Flanged

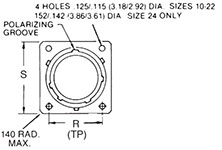

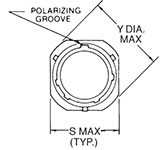

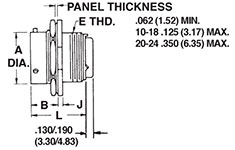

MS3470/PV70 MS3471/PV71 MS3472/PV72 B J R S Y Shell Size A Dia. Max. Overall Length 70, 71 72 70, 71, 72 70 72 70, 71 72 71 E Rear Thread UNEF-2A 8* .474 (12.04) 1.215 (30.86) .462 (11.73) - .078 (1.98) .594 (15.09) - .828 (21.03) - - 1/2-20 10 .591 (15.01) 1.215 (30.86) .462 (11.73) .493 (12.52) .078 (1.98) .719 (18.26) .812 (20.62) .954 (24.23) 1.141 (28.98) 1.082 (27.48) 5/8-24 12 .751 (19.08) 1.215 (30.86) .462 (11.73) .493 (12.52) .078 (1.98) .812 (20.62) .938 (23.83) 1.047 (26.59) 1.266 (32.16) 1.176 (29.87) 3/4-20 14 .876 (22.25) 1.215 (30.86) .462 (11.73) .493 (12.52) .078 (1.98) .906 (23.01) 1.031 (26.91) 1.141 (28.98) 1.360 (34.54) 1.270 (32.26) 7/8-20 16 1.001 (25.43) 1.215 (30.86) .462 (11.73) .493 (12.52) .078 (1.98) .969 (24.61) 1.125 (28.58) 1.234 (31.34) 1.453 (36.91) 1.364 (34.64) 1-20 18 1.126 (28.60) 1.215 (30.86) .462 (11.73) .493 (12.52) .078 (1.98) 1.062 (26.97) 1.203 (30.56) 1.328 (33.73) 1.532 (38.91) 1.458 (37.03) 1-1/16-18 20 1.251 (31.78) 1.275 (32.40) .587 (14.91) .587 (14.91) .110 (2.79) 1.156 (29.36) 1.297 (32.94) 1.453 (36.91) 1.688 (42.88) 1.708 (43.38) 1-3/16-18 22 1.376 (34.95) 1.275 (32.40) .587 (14.91) .587 (14.91) .110 (2.79) 1.250 (31.75) 1.375 (34.93) 1.578 (40.08) 1.766 (44.86) 1.708 (43.38) 1-5/16-18 24 1.501 (38.13) 1.275 (32.40) .620 (15.75) .620 (15.75) .110 (2.79) 1.375 (34.93) 1.500 (38.10) 1.703 (43.26) 1.891 (48.03) 1.832 (46.53) 1-7/16-18 * MS3471/PV71 and MS3472/PV72 not available in size 8. ITT CANNON PV SERIES JAM NUT

MS3474/PV74

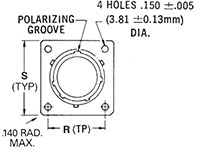

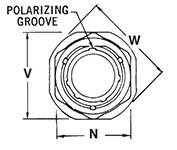

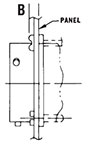

Shell A Dia. L B J N V W E Thread UNEF-2A 8 .474 1.215 .707 .113 .767 .954 1.078 1/2-20 10 .591 1.215 .707 .113 .892 1.078 1.203 5/8-24 12 .751 1.215 .707 .113 1.079 1.266 1.391 3/4-20 14 .876 1.215 .707 .113 1.205 1.391 1.516 7/8-20 16 1.001 1.215 .707 .113 1.329 1.516 1.641 1-20 18 1.126 1.215 .707 .113 1.455 1.641 1.766 1-1/16-18 20 1.251 1.275 .772 .148 1.579 1.828 1.954 1-3/16-18 22 1.376 1.275 .772 .148 1.705 1.954 2.078 1-5/16-18 24 1.501 1.275 .772 .148 1.829 2.078 2.203 1-7/16-18 PANEL CUTOUTS & THICKNESSITT CANNON PV SERIES PV FLANGED PANEL CUTOUTS

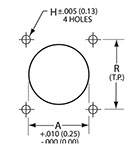

PVTBF Thru-Bulkhead MS3470/ MS3472/PV72 Wide Flange Shell Size A Diameter R H Screw Size R H Screw Size 8 .620 (15.75) .594 (15.09) .125 (3.17) #4 - - - 10 .740 (18.80) .719 (18.26) .125 (3.17) #4 .812 (20.62) .155 (3.97) #6 12 .864 (21.95) .812 (20.62) .125 (3.17) #4 .938 (23.93) .155 (3.97) #6 14 .990 (25.15) .906 (23.01) .125 (3.17) #4 1.031 (26.19) .155 (3.97) #6 16 1.118 (28.40) .969 (24.61) .125 (3.17) #4 1.125 (28.58) .155 (3.97) #6 18 1.240 (31.50) 1.062 (26.97) .125 (3.17) #4 1.203 (30.56) .155 (3.97) #6 20 1.366 (34.70) 1.156 (29.36) .125 (3.17) #4 1.297 (32.94) .155 (3.97) #6 22 1.490 (37.85) 1.250 (31.75) .125 (3.17) #4 1.375 (34.92) .155 (3.97) #6 24 1.616 (41.05) 1.375 (34.92) .155 (3.97) #6 1.500 (38.10) .155 (3.97) #6 ITT CANNON PV SERIES PV74 JAM NUT MS3474

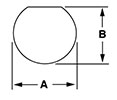

Shell Size A Diameter ± .005 (0.13) B ± .005 (0.13) 10 .697 (17.70) .661 (16.79) 12 .895 (22.73) .824 (20.93) 14 1.010 (25.65) .948 (24.08) 16 1.135 (28.33) 1.072 (27.23) 18 1.260 (32.00) 1.197 (30.40) 20 1.385 (35.18) 1.322 (33.58) 22 1.510 (38.35) 1.447 (36.75) 24 1.635 (41.53) 1.572 (39.93) ITT CANNON PV SERIES PANEL THICKNESS MS3470/PV70 Narrow Flange

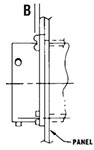

*B Max Size Narrow Flange MS3470/PV70 Thru-Bulkhead PVTBF Wide Flange MS3472/PV72 8 10 12 14 16 18

20 22 24

* (Screw Head Front Mtg. or Panel Thickness plus Screw Head Rear Mtg.) DUMMY RECEPTACLES & METAL DUST CAPSITT CANNON PV SERIES DUMMY RECEPTACLES & METAL DUST CAPS

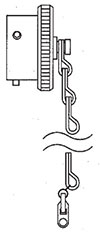

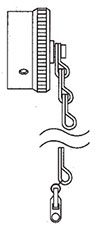

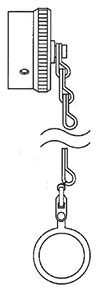

Dummy Receptacles Metal Dust Caps*

Metal Dust Caps Shell Dummy Receptacle For For Receptacle For Receptacle 8 MS3115-8** MS3180-8CA MS3181-8CA MS3181-8NA 10 MS3115-10** MS3180-10CA MS3181-10CA MS3181-10NA 12 MS3115-12** MS3180-12CA MS3181-12CA MS3181-12NA 14 MS3115-14** MS3180-14CA MS3181-14CA MS3181-14NA 16 MS3115-16** MS3180-16CA MS3181-16CA MS3181-16NA 18 MS3115-18** MS3180-18CA MS3181-18CA MS3181-18NA 20 MS3115-20** MS3180-20CA MS3181-20CA MS3181-20NA 22 MS3115-22** MS3180-22CA MS3181-22CA MS3181-22NA 24 MS3115-24** MS3180-24CA MS3181-24CA MS3181-24NA * Sash chain version for attachment to mounting screw or flanged receptacles. Sash chain with ring for mounting to jam nut receptacle **Select plating W = Olive drab over cadmium A = Anodized L = Electroless nickel |

|

ITT CANNON PV SERIES STANDARD CABLE CLAMPS

Straight Clamp 90 Degree Cable Entry Shell Size Low Cost Self-Locking Low Cost Self-Locking Max. Min. 8 M85049/52-1-8* M85049/52S8* M85049/51-1-8* M85049/51S8* .204 (5.18) .125 (3.18) 10 M85049/52-1-10* M85049/52S10* M85049/51-1-10* M85049/51S10* .286 (7.26) .187 (4.75) 12 M85049/52-1-12* M85049/52S12* M85049/51-1-12* M85049/51S12* .416 (10.57) .291 (7.39) 14 M85049/52-1-14* M85049/52S14* M85049/51-1-14* M85049/51S14* .476 (12.09) .351 (8.92) 16 M85049/52-1-16* M85049/52S16* M85049/51-1-16* M85049/51S16* .625 (15.88) .501 (12.72) 18 M85049/52-1-18* M85049/52S18* M85049/51-1-18* M85049/51S18* .706 (17.93) .518 (13.16) 20 M85049/52-1-20* M85049/52S20* M85049/51-1-20* M85049/51S20* .831 (21.11) .581 (14.76) 22 M85049/52-1-22* M85049/52S22* M85049/51-1-22* M85049/51S22* .956 (24.28) .644 (16.36) 24 M85049/52-1-24* M85049/52S24* M85049/51-1-24* M85049/51S24* 1.081 (27.46) .706 (17.93) * Select plating code to match connector plating * N = Electroless Nickel (High Temp 200ºC Fluid Resistant ) * W = Olive Drab over Chromate over Cadmium over Electroless Nickel (500-Hour Salt Spray) Description Part Number Prefix Straight 90º 45º

M85049/7 M85049/9 M85049/11 X X X

M85049/23 M85049/24 M85049/25 X X X

M85049/6 M85049/8 M85049/10 X X X

M85049/82 M85049/83 M85049/84 X X X

M85049/53 M85049/54 M85049/55 X X X

*If Military Standard versions won't work for your applications, please contact us with your requirements. All dimensions in inches (millimeters in parentheses) unless otherwise stated. |

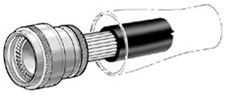

WIRE STRIPPING AND CONTACT CRIMPINGITT CANNON PV SERIES WIRE STRIPPING AND CONTACT CRIMPING

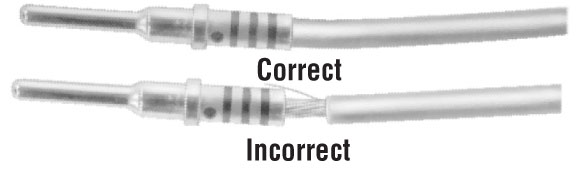

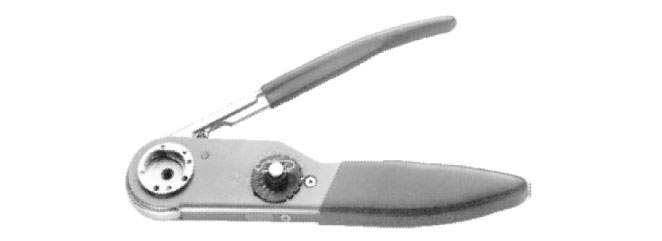

STEP 1: Strip wires. (See above for correct strip length for contact.) Insert wire into rear of contact. Wire insulation must press against rear of contact. Wire must be visible through inspection hole. STEP 2: Use M22520/1-01 crimp tool with proper crimp location M22520/1-02.

Contact Size Color 20 Red 16 Blue 12 Yellow STEP 3: Insert contact and wire into tool jaws. To crimp, squeeze handles together fully until ratchet releases and allows handles to expand; otherwise, contact cannot be extracted from tool jaws. Maintain slight insertion pressure on wire while crimping contact to wire. CONTACT INSERTIONITT CANNON PV SERIES CONTACT INSERTION

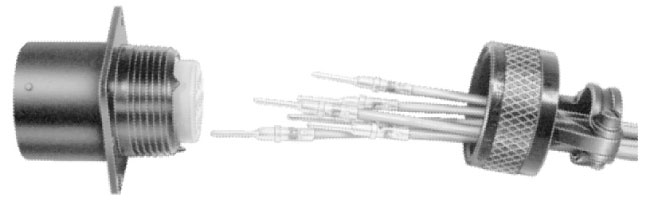

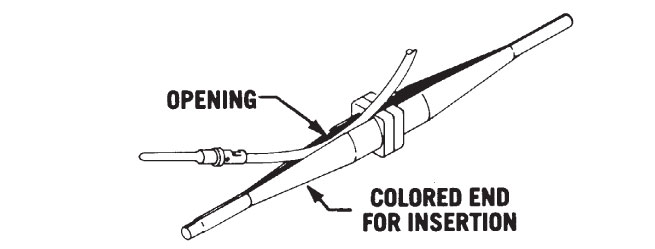

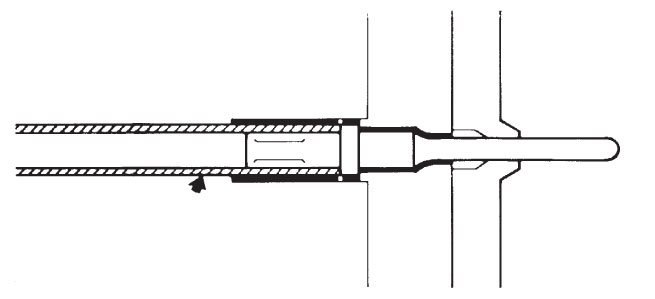

STEP 1: Remove backshell and put wired contacts through cable clamp opening. STEP 2: Use colored end of CIET tool for insertion. Place wire into tool at large opening. To facilitate contact insertion, a six inch minimum free length of wire is recommended. STEP 3: Slide back tool on wire while holding thumb against wire at opening. Wire will slip into tool.

STEP 4: With tool pressed against shoulder of contact, starting at the center cavity, insert wired contact and tool into properly-identified cavity at rear of plug with firm, even pressure. Do not use excessive pressure. STEP 5: When contact bottoms, a slight click can be heard as tines of metal retaining clip snap into place behind contact shoulder. STEP 6: Check face of plug or receptacle for proper contact installation. In socket inserts with a large number of contacts, cavities are identified in a spiral pattern. A projecting line from the spiral indicates omission of a letter; a broken circle around a cavity indicates transition between capitals and lower case and double letters.

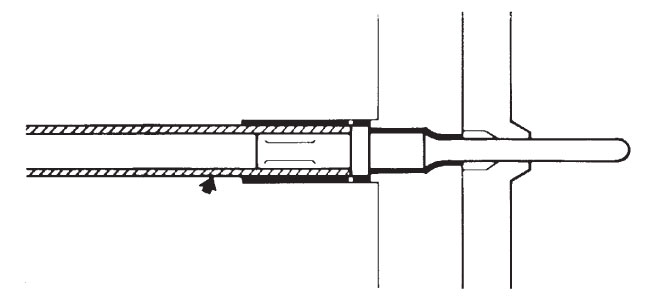

STEP 7: Withdraw tool from rear of plug. To be sure that contact is locked, pull back lightly on wire. Then remove tool from wire and proceed with other contacts. STEP 8: After all contacts are inserted, fill unwired cavities with sealing plugs (insert head in first and trim, leave end protruding for ease of removal), assemble backshell on rear of connector. CONTACT EXTRACTIONITT CANNON PV SERIES CONTACT EXTRACTION

STEP 1: Remove backshell and slide back along wires to allow access. To extract a contact, use white end of CIET tool. Place wire into tool at large opening. Slide back tool on wire while holding thumb against wire at opening. Wire will slip into tool. STEP 2: Push tool into rear of plug until it bottoms. At this point, tool releases tines on retaining clip so that contact can be extracted. STEP 3: While maintaining slight insertion force on tool, firmly hold wire against serrated shoulder at center of tool and extract both wired contact and tool from plug. *Important Note: Microsection the contact to verify crimp quality. |

Philadelphia

19116

Click here for the contact information of the branch nearest you.