Amphenol AIB/GT Series Connectors

IMPROVED COUPLING OVER THREADED COMMERCIAL SAE-AS50151 (MIL-DTL-5015)

The Amphenol AIB/GT series replaces the threaded coupling used in commercial SAE-AS50151 (MIL-DTL-5015) connectors with a positive, quick-mating, three-point reverse bayonet lock for improved performance. These Amphenol AIB/GT Series connectors are an ideal cost-effective option for applications requiring reliability in harsh environments, and are the world-standard for rail, mass transit, and military ground vehicle applications. The Amphenol AIB/GT series has the same shell dimensions, contact layouts, contacts, and performance characteristics as the SAE-AS50151 (MIL-DTL-5015) threaded connectors; however, the two series do not intermate. These connectors are sealed to withstand moisture, condensation, vibration and flash-over. Over 180 contact layouts are available, in variations that allow for just power, just signal, or a mix of both contact types. There is also an additional option of high-power RADSOK contacts. For our full product descriptions of the Amphenol AIB/GT series, please see the specifications below.

Learn more about how versatile Amphenol AIB connectors can be by checking out our "PEI-Connects" blog post called: "Withstand Rugged Conditions with Dependable Amphenol Connectors".

|

FEATURESAMPHENOL AIB/GT SERIES FEATURES

MATERIALS & FINISHESAMPHENOL AIB/GT SERIES MATERIALS & FINISHES

Shell Aluminum alloy (can be grounded)

Shell Plating Cadmium, Anodized, Electroless Nickel, Zinc Alloy, or Grey Zinc Nickel

Contacts Copper alloy

Contact Platings Hard silver plating or gold plating

Insulator* Neoprene

Seals Silicone, Neoprene, or Viton®**

* Optional zero-halogen and high-temperature insulators are available. Contact us for information. ** Viton® is a registered trademark of DuPont DOW Elastomers ELECTRICAL DATAAMPHENOL AIB/GT SERIES ELECTRICAL DATA

Operating Voltage/Test Voltage according to MIL-DTL-5015H The indicated values for the operating voltage are limits concerning the electrical function. When the working voltage exceeds 50V, safety precautions must be in accordance with the following standards: VDE 0100, IEC 309-1

or applicable national standards.

Current Rating Contact Size Test Current (Amps) 16/16S 13 12 23 (60)* 8 46 (69)* 4 80 (120)* 0 150 (225)* *Test amps, multiconductor using Radsok contact Altitude Voltage Derating* Chart Nominal Distance Operating Voltage* Standard Sea Level Conditions Pressure Altitude† Pressure Altitude† MS Service Rating Airspace Creepage DC V AC VRMS Minimum Flashover Voltage Test Voltage AC (RMS) Minimum Flashover Voltage Test Voltage AC (RMS) Minimum Flashover Voltage Test Voltage AC (RMS) I 1/32 1/16 250 200 1,400 1,000 550 400 325 260 A 1/16 1/8 700 500 2,800 2,000 800 600 450 360 D 1/8 3/16 1,250 900 3,600 2,800 900 675 500 400 E 3/16 1/4 1,750 1,250 4,500 3,500 1,000 750 550 440 B 1/4 5/16 2,450 1,750 5,700 4,500 1,100 825 600 480 C 5/16 1 4,200 3,000 8,500 7,000 1,300 975 700 560 * No attempt has been made to recommend operating voltages. The designer must determine own operating voltage by the application of a safety factor to the above derating chart to compensate for circuit transients, surges, etc. † Not corrected for changes in density due to variations in temperature. Wire Range Sizes 26 AWG to 0 AWG (see contact selection)

Contact Resistance per MIL-DTL-5015H p 3.15 Contact Size Contact Resistance Potential Voltage Drop in Millivolts Max. 16/16S 6 21 12 3 20 8 1/(0.44)* 12 (20)* 4 0.5/(0.23)* 10 (18)* 0 0.2/(0.18)* 10 (27)* *Using Radsok contact Insulation Resistance @77˚F (25˚C) > 5,000 Megohms

MECHANICALAMPHENOL AIB/GT SERIES MECHANICAL

Operating Temperature -67˚ to +257˚F (-55˚ to +125˚C) Neoprene/ Low Smoke Zero Halogen (Flame Retardant)

-58˚ to +392˚F (-50˚ to +200˚C) Viton Sealing 33-foot submersible

Sealed when mated. ≈ IP 67 and NEMA 4P Wire Sealing Range The connector is designed for individual wire sealing. Sealing of an outer

cable jacket on multiconductor cables must be accomplished with an

appropriate endbell. Sealing is only guaranteed if wires used are

according to MIL-W-5086 or within the listed ranges.

Sealing Range Contact Size Inches MM 16 .064 - .130 1.62 - 3.30 12 .114 - .170 2.89 - 4.31 8 .164 - .255 4.16 - 6.47 4 .272 - .370 6.90 - 9.30 0 .415 - .550 10.50 - 13.97 Insulation Strip Lengths

Mating Life 2,000 cycles minimum (commercial) 500 cycles minimum (military)

Salt Spray Olive drab chromate over cadmium - 500 hours

Non-conductive black alloy - 48 to 200 hours Conductive black alloy - 48 to 200 hours Black anodized - 500+ hours Electroless nickel - 48 hours 500+ hours grey zinc nickel Heat Neoprene 257˚F (+125˚C); Low-smoke, zero-halogen (LSZH) 347˚F (+175˚C); Viton 392˚F (+200˚C)

Chemical Resistance Diesel Fuel, JP-4 , Hydraulic Fluid, Gasoline

48-hour intermittent spray for each chemical with no deterioration, followed by Contact Retention (CR), Insulation Resistance (IR), Dielectric Withstanding Voltage tests (DWV) Corrosion Resistance Olive Drab Cadmium-Plated 48 hours per MIL-DTL-5015 (3.17/4.6.13)

Fluid Immersion Hydraulic Fluid 20 hours per MIL-DTL-5015 (3.19/4.6.15)

Lubrication Oil 20 hours per MIL-DTL-5015 (3.19/4.6.15) Vibration Per MIL-STD-810C, method 516.2, procedure VIII

1.0 g peak from 5 to 25 Hz .030” double amplitude from 25 to 57 Hz 5g peak from 57 to 500 Hz Basic Shock Per MIL-STD-810C, method 516.2, procedure I pulse at half-sine

wave of 30g for 11 seconds

Gun fire Shock Per MIL-STD-810C, method 516.2, procedure IV pulse at half-sine

wave of 100g for 1.5 seconds

Ballistic Shock Per MIL-STD-810C, method 516.2, procedure IV pulse at half sine

wave of 200g for .5 seconds

Contact Type Solder, crimp, PC, first-mate last-break or thermocouple. Hard silver or gold plating.

Contact Insertion From rear with simple hand-tool. Removable, 5 cycles minimum.

Contact Retention Pin and socket contacts are designed to resist severe vibration and

repeated connection and disconnection. Contact retention and separation

is tested according to MIL-DTL-5015H (4.6.6.1)

Contact Size Retention Force Min. 16 10 12 15 8 20 4 20 0 25 Number of Circuits 1 to 85

Rear Accessories Maximum Torque

Size In./Lb. Max. 10SL 26 14S 44 16 50 16S 50 18 55 20 65 22 85 24 90 28 114 32 120 36 153 40 170 Thermocouple Codes Material Color Code Code Iron Black IR Constantan Yellow CON Copper alloy - Cu Chromel White CH Alumel Green AL Thermocouple Types: Color code is identified by small dot on wire well end of contact. Approvals/ Agency Listing UL File# E115497

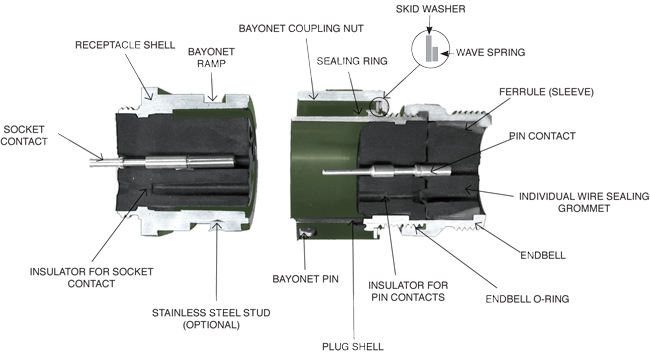

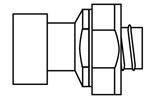

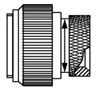

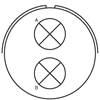

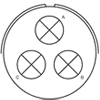

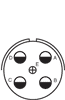

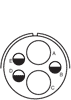

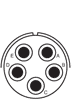

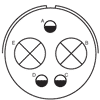

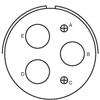

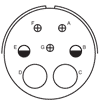

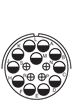

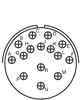

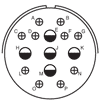

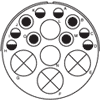

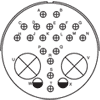

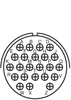

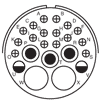

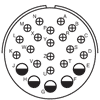

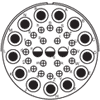

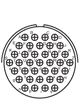

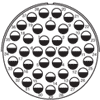

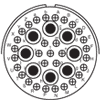

AMPHENOL AIB/GT SERIES CROSS-SECTION

COMPONENTSAMPHENOL AIB/GT SERIES COMPONENTS

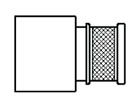

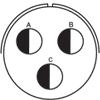

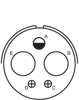

PLUGS RECEPTACLES O-Ring AIB/GT AIBC/ACA-B AIB/GT AIBC/ACA-B Barrel/Shell

Insert/

Contacts

Wave Spring and

Coupling Nut

Individual Wire

Ferrule/Sleeve

Endbell/

|

|

AMPHENOL AIB/GT SERIES APPLICATIONS

Industrial environments requiring extreme environmental reliability and ease of mating and unmating, such as:

|

|

STEP 1: TYPEHOW TO ORDER

This section shows all of the standard possibilities for AIB/GT series connectors. Follow the nine steps to create a description of the connector best suited to your application. This is not an Amphenol part number, but gives you a convenient way to select your connector. Contact us with the description for a valid Amphenol part number. If you prefer to select the Amphenol part number, see the How-To-Order guide.Many additional options not shown are available. Contact us if your needs are not met by the options on the next page. CREATE YOUR PART NUMBER USING THESE NINE STEPS

1 2 3 4 5 6 7 8 9 AIB 6HD F A 24-28 P W S -472 CONNECTOR SHELL STYLE END BELLS CABLE LAYOUT CONTACT ROTATION CONTACT PLATING/ STEP 1: SELECT CONNECTOR TYPE

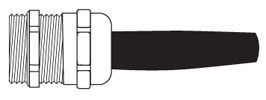

AIB* AIBC* * AIBC is the commercial version of the AIB. It comes without wear pins in the receptacles and without wave springs in the coupling nuts. Note: AIBC are fully intermateable with all reverse bayonet connectors. STEP 2: SHELLSTEP 2: SHELL STYLE, PLUG OR RECEPTACLE

6B Box Mount

6 Standard Plug G6 Shielded Plug 0 Front Wall Mount with 30 Rear Wall Mount with 1 Cable Mount 20 Front Box Mount

4

6HD

70 Rear Mount Jam Nut 2 Front Box Mount 7 Rear Mount Jam Nut TB Thru Bulkhead

STANDARD SPECIALS -- Call with NPT Thread Size, Sealtite Conduit Diameter or Cable Outside Diameter

Shielded Cable/Heat Shrink Shielded Cable Banding Gland Seal Mesh Grip

Low Cost Gland Seal Internal Thread Version Conduit Metal

STEP 3&4: CABLE CLAMP OR BOOTSTEP 3: SELECT CABLE CLAMP OR BOOT (IF APPLICABLE)

RV G G2 U L A Unsealed T MS Style P Potting

STEP 4: SELECT CABLE CLAMP OR BOOT (IF APPLICABLE)

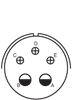

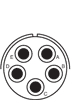

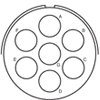

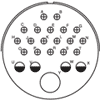

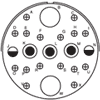

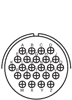

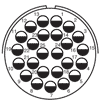

Heat Shrink Boot A MS3057-A C MS3057-C 9767 STEP 5: LAYOUTSTEP 5: SELECT LAYOUT

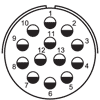

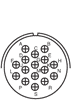

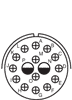

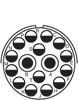

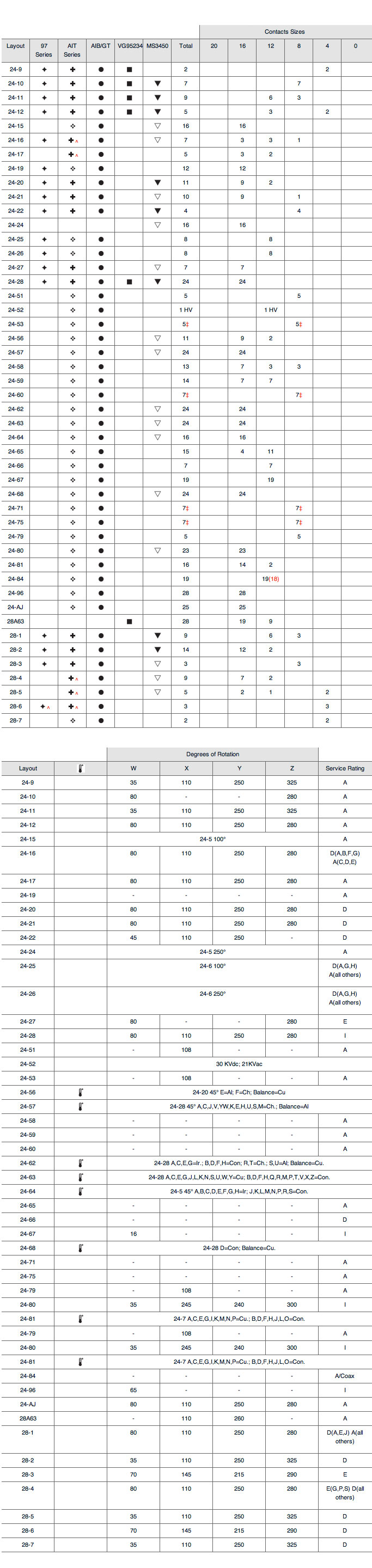

LAYOUTS BY NUMBER OF CONTACTS

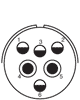

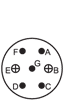

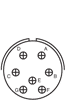

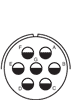

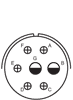

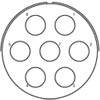

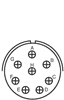

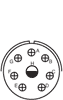

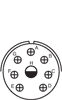

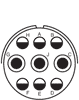

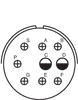

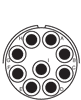

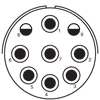

SERIES KEY: AIB AIT 97 VG95234 MS3450 Thermocouple Number of Contacts: 1 Through 7

1 Contact

Layout 8S-1 10S-2 12S-4 12-5 14S-4 14-3 16S-3 16-2 # of Contacts 1-#16 1-#16 1-#16 1-#12 1-#16 1#8 1#16 1-#12 Series

Service Rating A A D D D A B E

Layout 16-12 18-6 18-7 18-16 18-420 20-2 22-7 24-52 # of Contacts 1-#4 1-#4 1-#8 1-#12 1-#12 1-#0 1-#0 1-#12 Series

Service Rating A D B C 17 KVac D E 21 KVac 2 Contacts

Layout 10SL-4*★ 12S-3* 12S-6 14S-9* 16S-4 16A11 16-11 16-13 18-3 # of Contacts 2-#16 2-#16 2-#16 2-#16 2-#16 2-#12 2-#12 2-#12 2-#12 Series

Service Rating A A Thermo- A D A A Thermo- D

Layout 18-14 20-12 20-23 22-1 22-8 22-11 24-1 # of Contacts 1-#16, 1-#4 1-#16, 1-#4 2-#8 2-#8 2-#12 2-#16 1-#12, 1-#0 Series

Service Rating A A A D E B D 3 Contacts

Layout 24-9 28-7 32-5 10SL-3★ 14S-1 14S-7 14S-12 16S-5 # of Contacts 2-#4 2-#4 2-#0 3-#16 3-#16 3-#16 3-#16 3-#16 Series

Service Rating A D D A A A A A 3 Contacts (Continued)

Layout 16S-6 16-7 16-10 18-5 18-22 20-3 20-6 20-19 # of Contacts 3-#16 2-#16, 1-#8 3-#12 1-#16, 2-#12 3-#16 3-#12 3-#16 3-#8 Series

Service Rating A A A D D D D A

Layout 20-51 20-59 22-2 22-6 22-9 22-21 22-80 28-3 # of Contacts 3-#8 3-#8 for #10 or #12 wire 3-#8 1-#16, 2-#8 3-#12 2-#16; 1-#0 3-#8 for #10 or 12 wire 3-#8 Series

Service Rating A A D D E A A E 4 Contacts

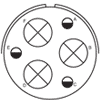

Layout 28-6 28-72 36-4 40-AV 12SL-844 14S-2* 14S-10 # of Contacts 3-#4 3-#4 (co-ax) RG-59A/U or RG-62A/U 3-#0 3-#2/0 4-#16 4-#16 4-#16 Series

Service Rating D (co-ax) D(A); A(B,C) D I I I 4 Contacts (Continued)

Layout 16-9 16-59 18-4* 18-10* 18-13 18-15 20-4* 20-20 20-24 # of Contacts 2-#16, 2-#12 4-#12 4-#16 4-#12 3-#12, 1-#8 4-#12 4-#12 3-#12, 1-#4 2-#16, 2-#8 Series

Service Rating A A D A A Thermo- D A A

Layout 22B22 22-4 22-10 22-22* 24-4 24-22 32-17 # of Contacts 4-#8 2-#12; 2-#8 4-#16 4-#8 3-#16; 1-#0 4-#8 4-#4 Series

Service Rating A A E A D D D

Layout 32-58 36-5 36-51 36-64 36-65 # of Contacts 4-#4 (co-ax) RG-161/U 4-#0 2-#4, 2-#0 4-#0 (co-ax) RG-11U; 4-#0 (co-ax) RG-59/U; Series

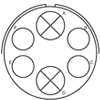

Service Rating (co-ax) A D (co-ax) (co-ax) 5 Contacts

Layout 40-57 40-66 40-88 14S-5* 16S-8* 18-11* 18-20 # of Contacts 4-#0 4-#0 (co-ax) RG-63B/U 4-#0 (co-ax) RG-115A/U 5-#16 5-#16 5-#12 5-#16 Series

Service Rating E (co-ax) E/(co-ax) I A A A

Layout 18-29 18-30 18-31 20-14 22-12 22-13 22-34 24-12 # of Contacts 5-#16 5-#16 5-#16 3-#12; 2-#8 3-#16; 2-#8 1-#16; 4-#12 2-#16; 3-#12 3-#12; 2-#4 Series

Service Rating A A A A D D(E) A(A,B,C,D) D A

Layout 24-17 24-51 24-53 24-79 28-5 32-1 32-3 # of Contacts 3-#16; 2-#12 5-#8 5-#8 5-#8 2-#16; 1-#12; 2-#4 3-#12, 2-#0 2-#16, 3-#4 Series

Service Rating D B; E for AWG #10 or 12 wire A; C; D for AWG #18 wire A A D E(A); D(All others) E 6 Contacts

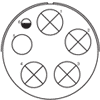

Layout 32-63 32-79 40-5 40-75 14S-6* 18-12 20-8 # of Contacts 5-#4 1-#8; 4-#4 5-#0 4-#0; 1-#12 6-#16 6-#16 4-#16, 2-#8 Series

Service Rating D D A E I A I 6 Contacts (Continued)

Layout 20-17 20-22 20-66 22-5 22-15 22-24 28-22 28-82 # of Contacts 1-#16; 5-#12 3-#16; 3-#8 1-#16; 5-#12 for #10 wire 4-#16; 2-#12 1-#16; 5-#12 4-#16; 2-#12 3-#16; 3-#4 4-#12; 2-#8 Series

Service Rating A A A D A(A,B,C,E,F); E(D) D(C,D,E) A(A,B,F) D D 7 Contacts

Layout 36-3 36-6 40-74 14SA7 16S-1* 18-9 18-17 # of Contacts 3-#12; 3-#0 4-#4; 2-#0 1-#12; 1-#4(co-ax) RG-62/U; 4-#0(co-ax) RG-9B/U or 7-#16 7-#16 5-#16; 2-#12 5-#16; 2-#12 Series

Service Rating D A A/(co-ax) A A I I 7 Contacts Continued

Layout 20-15* 20-57 22-26 22-28 22-33 24-2 24-3 # of Contacts 7-#12 7-#12 for #14 or 16 wire 5-#16; 2-#12 7-#12 7-#16 7-#12 5-#16; 2-#12 Series

Service Rating A A 1/8" spacing D/A D(A,B,C,D); A(E,F,G) D D

Layout 24-10 24-16 24-27 24-60 24-66 24-71 24-75 # of Contacts 7-#8 3-#16; 3-#12; 1-#8 7-#16 7-#8 or 12 wire 7-#12 5-#8 for #10 or 12 wire, 2-#8 2-#8 for #16 wire; 5-#8 Series

Service Rating A D(A,B,F,G) A(C,D,E) E A D A D

Layout 28-10 32-10 36-73 36-77 36-63 40-67 # of Contacts 3-#12; 2-#8; 2-#4 3-#16; 2-#8; 2-#4 7-#4 (co-ax) RG-62B/U 7-#4 7-#4 (co-ax) RG-58/U 7-#4 Series

Service Rating D(G); A(All others E(A,F); B(G); D(B,E); A(C,D) (co-ax) D (co-ax) D * Most popular ★ Pins in receptacle, sockets in plug only for 97/AIT/MS series ¤ Special arrangement for MS3450 Series ●different per 1651 STD: 5-#12; 2-#4 Read Less Number of Contacts: 8 Through 21

8 Contacts

Layout 18-8* 20-7* 20-9 20-79 22-18 22-23 22-36 22-65 # of Contacts 7-#16; 1-#12 8-#16 7-#16; 1-#12 7-#16; 1-#12 for #16 wire 8-#16 8-#12 8-#12 8-#12 for #14 or 16 wire Series

Service Rating A(B,C,F,G) I(all others) DCH; A(All others) DCH; A(All others) D(A,B,F,G,H); A(C,D,E) D(H); A(All others) D(H); A(All others) D(H); A(All others) 9 Contacts

Layout 24-6 32-15 32-52 32-57 40-AD 20AB 20-16 # of Contacts 8-#12 6-#12; 2-#0 6-#12; 2-#0 6-#12; 2-#0 (co-ax) RG-7/U 4-#8, 4-#0 9-#12 7-#16; 2-#12 Series

Service Rating D(A,G,H); A(All Others) D D (co-ax) A D(J), I(All others) A 9 Contacts Continued

Layout 20-18* 20-21 22-16 22-17 22-20 22-27 24-11 # of Contacts 6-#16; 3-#12 8-#16; 1-#12 6-#16; 3-#12 8-#16; 1-#12 9-#16 8-#16; 1-#8 6-#12; 3-#8 Series

Service Rating A A A D(A); A(All others) A D(J), A(All others) A

Layout 28-1 28-4 28-84 28AY 32-3 32-75 # of Contacts 6-#12; 3-#8 7-#16; 2-#12 9-#8 5-#16; 4-#4 4-#16; 2-#12 2-#12; 7-#8 (co-ax) RG-180B/U Series

Service Rating D(A,J,E); A(All others) E(G,P,S); D(All others) A A D (co-ax) 10 Contacts

Layout 18-1* 18-19 18-24 20-58 24-21 28-19 # of Contacts 10-#16 10-#16 10-#16 5-#16; 5-#12 9-#16; 1-#8 6-#16; 4-#12 Series

Service Rating A(B,C,F,G) I(all others) A A(B,C,F,G); I(balance) A D B(H,M); D(A,B) 11 Contacts

Layout 20-33 24-20 36-14 40-67 40-72 40-80 # of Contacts 11-#16 9-#16; 2-#12 6-#16; 5-#12; 5-#8 1-#16; 10-#4 (co-ax) RG-59/U 1-#16; 10-#4 (co-ax) RG-9B/U 10-#4; 1-#16 Series

Service Rating A D D A (co-ax) A (co-ax) A 12 Contacts

Layout 22-63 24-19 28-6 28-9 28-18 28-51 # of Contacts 18-#16; 4-#12 12-#16 10-#16; 2-#12 6-#16; 6-#12 12-#16 12-#12 Series

Service Rating A A E(L,M); D(B) A(balance) D C(M); D(G,H,J,K,L); A(A, B); I(C,D,E,F) A 13 14 Contacts

Layout 20-11 20-25 20-30 22-70 24-58 32-14● 20-27* # of Contacts 13-#16 13-#16 13-#16 5-#16; 8-#12 7-#16; 3-#12; 3-#8 13-#12 14-#16 Series

Service Rating I I I A A D A

Layout 22-19* 24-59 28-2 29-20 32-4 32-9 36-78 # of Contacts 14-#16 7-#16; 7-#12 12-#16; 2-#12 4-#6; 10-#12 12-#16; 2-#12 (co-ax) RG-9B/U 12-#6; 2-#4 (co-ax) RG-9B/U 12-#8; 2-#16 Series

Service Rating A A D A A (F,J,K,N) D A 15 Contacts 16 Contacts

Layout 24-65 28-17* 32-12 40-5¤ 24-5 24-7* 28-66 # of Contacts 14-#16; 11-#12 15-#16 10-#16; 5-#12 6-#12; 4-#8; 2-#4; 3-#0 16-#16 14-#16; 2-#12 (co-ax) RG-9B/U 14-#12; 2-#8 Series

Service Rating A B(R); D(M-P); A(A-L) A(C,D,E,F,G); D(all others) A A A A

Layout 28-74 28-75 28-79 32-68 32-82 36-14 # of Contacts 9-#16; 4-#8; 3-#8 for #10 wire 9-#16; 7-#8 for #10 wire 7-#8; 9-#16 12-#12; 4-#4 (co-ax)RG-58C/U 12-#16; 4-#4 6-#16; 5-#12; 5-#8 Series

Service Rating A A A A (co-ax) A D 17 Contacts 19 Contacts

Layout 20-29* 28-59 36-13 20A48 20-26 22-14* 24-67 # of Contacts 17-#16 10-#16; 7-#12 15-#16; 2-#12 19-#16 19-#16 19-#16 19-#12 Series

Service Rating A A E(N,P,Q); A(all others) I A A I 20 Contacts 21 Contacts

Layout 24-84 32-76 28-16 36-79 36-80 40-68 # of Contacts 1-#12; 19-#12 20-#16 20-#12 20-#12 for #10 wire 21-#8 Series

Service Rating A (co-ax) A A A A A * Most popular ★ Pins in receptacle, sockets in plug only for 97/AIT/MS series ¤ Special arrangement for MS3450 Series ●different per 1651 STD: 5-#12; 2-#4 Read Less Number of Contacts: 22 Through 85

22 23 Contacts

Layout 28-11* 36-1 36-22 40-7 24-80 # of Contacts 18-#16; 4-#12 18-#16; 4-#12 22-#12 18-#16; 2-#12; 2-#0 23-#16 Series

Service Rating A D D P, Q, U, V, W, X=A; D(balanced) I

Layout 32-6 32-13 32-16 32-60 32-62 40-2 # of Contacts 16-#16; 2-#12; 18-#16; 5-#12 16-#16; 2-#12; 15-#16; 8-#8 (co-ax) RG-124/U 16-#16; 2-#12; 23-#16 Series

Service Rating A D A A (co-ax) A (co-ax) D 23 Contacts (continued) 24 Contacts 25 Contacts

Layout 40-3 40-4 24-28* 24-AJ 32-25 # of Contacts 18-#16; 4-#12; 1-#4 16-#16; 2-#12; 3-#8; 2-#4 24-#16 25-#16 25-#12 Series

Service Rating D D I A A 26 Contacts 28 Contacts 29 Contacts

Layout 28-12* 28-13 40-6 24-96 28A63 40-10 # of Contacts 26-#16 26-#16 24-#16; 1-#12; 1-#0 28-#16 19-#16; 9-#12 16-#16; 9-#8; 4-#4 Series

Service Rating A A D I A A 30 Contacts 31 Contacts

Layout 32-8 32-56 40-1 32-31 36-9 36-18 # of Contacts 24-#16; 6-#12 24-#16; 6-#12 for #10 wire 24-#16; 6-#12 31-#16 14-#16; 14-#12; 2-#8; 1-#4 14-#16; 14-#12; 2-#8; 1-#4 Series

Service Rating A A D A A A 34 Contacts 35 Contacts

Layout 36-20 28-15* 32-7* 36-15 36-85 40-35 # of Contacts 30-#16; 2-#12; 2-#8 35-#16 28-#16; 7-#12 35-#16 35-#16 for #12 35-#12 Series

Service Rating A A I(A,B,H,J); A(all others) D(M); A(Balance) A/D D 36 Contacts 37 Contacts 38 Contacts 39 Contacts

Layout 40-64 28-21* 40-AG 36-54 36-55 # of Contacts 20-#16; 3-#12; 13-#8 (co-ax) RG-124/U 37-#16 38-#12 31-#16; 8-#8 31-#16; 8-#8 for #6 wire Series

Service Rating (co-ax) A A A A 42 Contacts 43 Contacts 44 Contacts 46 Contacts

Layout 32-53 32-59 40-AT 36-74 32-73 # of Contacts 37-#16; 5-#12 40-#16; 2-#8 (co-ax) RG-161/U 18-#16; 24-#12; 1-#8 43-#16; 1-#8 (co-ax); RG-187B/U 46-#16 Series

Service Rating I/E A (co-ax) A A (co-ax) A 47 Contacts

Layout 36-7* 36-8 36-16 36-17 36-60 # of Contacts 40-#16; 7-#12 46-#16; 1-#12 40-#16; 7-#12 40-#16; 7-#12 40-#16; 7-#12 for #10 wire Series

Service Rating A A A A A 48 Contacts

Layout 36-76 40-9 32-48 36-10* 36-11 # of Contacts 47-#16 24-#16; 22-#12; 1-#8 48-#16 48-#16 48-#16 Series

Service Rating A A I A A 52 Contacts

Layout 36-12 36-75 36-AF 32-414 36-52 # of Contacts 48-#16 48-#16 for #14 wire 48-#16 52-#16 52-#16 Series

Service Rating A A A A A 53 Contacts

Layout 36-403 36-59 36-71 # of Contacts 52-#16 50-#16; 3-#12 for #10 wire 50-#16; 3-#12 Series

Service Rating A A A 54 Contacts 55 Contacts 56 Contacts 59 Contacts

Layout 32-22 32-64 32-AF 36-66 40-61 # of Contacts 54-#16 54-#16 55-#16 52-#16; 4-#12 55-#16; 3-#12; 1-#8 Series

Service Rating A I A A A 60 Contacts 61 Contacts

Layout 40-53 40-62 40-85 32A69 40-63 # of Contacts 60-#16 60-#16 60-#16 for #14 wire 41-#20; 20-#16 61-#16 for #14 wire Series

Service Rating A A A I A 62 Contacts

Layout 40-70 40-73 40-81 40-82 # of Contacts 61-#16 61-#16 62-#16 for #14 wire 62-#16 Series

Service Rating A A A A 85 Contacts

Layout 40-56 # of Contacts 85-#16 Series

Service Rating A * Most popular ★ Pins in receptacle, sockets in plug only for 97/AIT/MS series ¤ Special arrangement for MS3450 Series ●different per 1651 STD: 5-#12; 2-#4 Read Less LAYOUTS BY SHELL SIZE

97 AIT AIB VG95234 MS3450 Thermocouple CONTACT METALLURGY KEY: Alumel (Al.) Chromel (Ch.) Constantan (Con.) Copper (Cu) Iron (Ir.) 8S-1 through 14S-5

Contacts Sizes Layout 97 Series AIT Series AIB/GT VG95234 MS3450 Total 20 16 12 8 4 0 8S-1

1 1 10S-2

1 1 10SL-3

3 3 10SL-4

2 2 10SL-51

2 2 10SL-52

2 2 10SL-53

2 2 10SL-54

3 3 10SL-55

3 3 10SL-56

2 2 10SL-57

2 2 10SL-58

3 3 10SL-59

2 2 10SL-60

2 2 10SL-61

2 2 10SL-62

3 3 10SL-63

3 3 10SL-64

3 3 12S-1

2 2 12S-2

2 2 12S-3

2 2 12S-4

2 2 12S-6

2 2 12S-51

2 2 12S-54

2 2 12S-55

2 2 12S-56

2 2 12S-57

2 2 12S-58

2 2 12S-59

2 2 12S-60

2 2 12S-61

2 2 12S-62

2 2 12SL844

4 4 12-5

1 1 14S-1

3 3 14S-2

4 4 14S-4

1 1 14S-5

5 5 ★Pins in receptacle, sockets in plug only ^5015 QPL not all configurations Degrees of Rotation Layout

W X Y Z Service Rating 8S-1 - - - - A 10S-2 - - - - A 10SL-3 - - - - A 10SL-4 63# - - - A 10SL-51

10SL-4 45° A=Ir; B=Con. 10SL-52

10SL-4 45° A=Cu; B=Con. 10SL-53

10SL-4 45° A=Al; B=Ch. 10SL-54

10SL-3 A=Ir; B=Con; C=Cu. 10SL-55

10SL-3 A=Al. B=Ch; C=Cu 10SL-56

10SL-4 A=Al; B=Ch 10SL-57

10SL-4 A=Ch; B=Con; C=Cu 10SL-58

10SL-3 A=Ch; B=Al; C=Cu 10SL-59

10SL-4 A=Ch; B=Al 10SL-60

10SL-4 A=Ir; B=Con. 10SL-61

10SL-4 A=Cu; B=Con 10SL-63

10SL-3 A,C=Con; B=Ch 10SL-64

10SL-3 A,C=Ch; B=Al 12S-1 12SL-3 100° A 12S-2 12SL-3 250° A 12S-3 70 145 215 290 A 12S-4 - - - - D 12S-6

12S-3 A=Con; B=Ir 12S-51

12S-3 315° A=Ch; B=Al 12S-54

12S-3 315° A=Ir; B=Con 12S-55

12S-3 45° A=Cu; B=Con 12S-56

12S-3 A=Al; B=Ch 12S-57

12S-3 60° A=Ch; B=Al 12S-58

12S-3 120° A=Ir; B=Con 12S-59

12S-3 A=Ir; B=Con 12S-60

12S-3 A=Cu; B=Con 12S-61

12S-3 A=Ch; B=Con 12S-62

12S-3 A=Ch; B=Al 12SL844 - - - - I 12-5 - - - - D 14S-1 - - - - A 14S-2 - 120 240 - I 14S-4 - - - - D 14S-5 - 110 - - I #Rotation commercial only, not MS-approved NOTE: 16S contacts are used in shell sizes 8S, 10S, 10SL, 12S, 14S & 16S Read Less 14S-6 Through 16S-54

Contacts Sizes Layout 97 Series AIT Series AIB/GT VG95234 MS3450 Total 20 16 12 8 4 0 14S-6

6 6 14S-7

3 3 14S-9

2 2 14S-10

4 4 14S-11

4 4 14S-12

3 3 14S-13

3 3 14S-14

4 4 14S-51

2 2 14S-52

4 4 14S-53

2 2 14S-54

6 6 14S-55

4 4 14S-56

4 4 14S-57

4 4 14S-58

3 3 14S-59

2 2 14S-60

2 2 14S-61

6 6 14S-63

6 6 14S-64

4 4 14S-65

6 6 14S-67

6 6 14S-68

4 4 14S-69

3 3 14S-70

4 4 14S-71

4 4 14S-72

2 2 14S-73

4 4 14S-74

4 4 14S-75

4 4 14S-76

4 4 14S-77

4 4 14S-78

2 2 14SA7

7 7 14-3

1 1 16S-1

7 7 16S-3

1 1 16S-4

2 2 16S-5

3 3 16S-6

3 3 16S-8

5 5 16S-14

3 3 16S-15

2 2 16S-16

2 2 16S-17

3 3 16S-52

2 2 16S-54

7 7 NOTE: 16S contacts are used in shell sizes 8S, 10S, 10SL, 12S, 14S & 16S Degrees of Rotation Layout

W X Y Z Service Rating 14S-6 90# - - - I 14S-7 90 180 270 - A 14S-9 70 145 215 290 A 14S-10 14S-2 100° I 14S-11 14S-2 250° I 14S-12 14S-2 100° A 14S-13 14S-2 260° A 14S-14 14S-2 100° I 14S-51

14S-9 90° A=Al; B=Ch 14S-52

14S-2 45° A,B=Cu; C=Al; D=Ch. 14S-53

14S-9 90° A=Ir; B=Con 14S-54

14S-6 45° A,C,E=Ir; B,D,F=Con 14S-55

14S-2 45° A,C=Ir; B,D=Con 14S-56

14S-2 45° A=Ir; B=Con; C,D=Cu 14S-57

14S-2 45° A,C=Al; B,D=Ch 14S-58

14S-7 45° A=Al; B=Ch; C=Cu 14S-59

14S-9 90° A=Cu; B=Con 14S-60

14S-9 90° A=Al; B=Ch 14S-61

14S-6 45° A=Al; B=Ch; C=Ir; D=Con; E,F=Cu 14S-63

14S-6 A,C=Al; B,D=Ch; E=Ir; F=Con. 14S-64

14S-2 A,C=Con; B,D=Cu 14S-65

14S-6 A,C,E=Cu; B,D,F=Con 14S-67

14S-6 A=Al; B=Ch; Balance=Cu 14S-68

14S-2 45° A=Ch; B=Con; C,D=Cu 14S-69

14S-7 A=Con; B=Ch; C=Cu 14S-70

14S-2 A,D=Ch; B,C=Al 14S-71

14S-2 A,B,D=Cu; C=Con 14S-72

14S-9 A=Con; B=Cu 14S-73

14S-2 A,B=Cu; C=Al; D=Ch 14S-74

14S-2 A,B=Ch; C,D=Al 14S-75

14S-2 A,B=Cu; C,D=Con 14S-76

14S-2 A,C=Al; B,D=Ch 14S-77

14S-2 A,D=Al; B,C=Ch 14S-78

14S-9 A=Ch; B=Al 14SA7 - - - - A 14-3 - - - - A 16S-1 80 - - 280 A 16S-3 - - - - B 16S-4 35 110 250 325 D 16S-5 70 145 215 290 A 16S-6 90 180 270 - A 16S-8 35 170 265 - A 16S-14 16S-5 110° A 16S-15 16S-4 100° D 16S-16 16S-4 250° D 16S-17 16S-5 250° A 16S-52

16S-4 A=Ch; B=Al 16S-54

16S-1 A=Al; B=C; Balance=Cu #Rotation commercial only. Not MS-approved. Not used for 97 series. Read Less 16S-55 Through 18-26

Contacts Sizes Layout 97 Series AIT Series AIB/GT VG95234 MS3450 Total 20 16 12 8 4 0 16S-55

7 7 16A11

2 2 16SA18

7 7 16SA19

7 7 16SA20

7 7 16SA21

7 7 16-2

1 1 16-7

3 2 1 16-9

4 2 2 16-10

3 3 16-11

2 2 16-12

1 1 16-13

2 2 16-52

2 2 16-53

4 2 2 16-55

3 3 16-56

2 2 16-57

3 3 16-58

3 3 16-59

4 4 16-60

2 2 16-62

2 2 18A31

10 10 18-1

10 10 18-3

2 2 18-4

4 4 18-5

3 1 2 18-6

1 1 18-7

1 1 18-8

8 7 1 18-9

7 5 2 18-10

4 4 18-11

5 5 18-12

6 6 18-13

4 3 1 18-14

2 1 1 18-15

4 4 18-16

1 1 18-17

7 5 2 18-18

7 5 2 18-19

10 10 18-20

5 5 18-22

3 3 18-23

10 10 18-24

10 10 18-25

2 2 18-26

2 2 †Socket only for 97 series ^5015 QPL not all configurations **Socket only for MS3450 series ***Pin only for MS3450 Degrees of Rotation Layout

W X Y Z Service Rating 16S-55

16S-1 A=Con; Balance=Cu 16A11 35 110 250 125 A 16SA18 16S-1 100° A 16SA19 16S-1 260° A 16SA20 16S-1 110° A 16SA21 16S-1 250° A 16-2 - - - - E 16-7 80 110 250 280 A 16-9 35 110 250 325 A 16-10 90 180 270 - A 16-11 35 110 250 325 A 16-12 - - - - A 16-13

35 110 250 325 A=Ir; B=Con 16-52

16-11 90° A=Al; B=Ch 16-53

16-9 70° A=Al; C=Ch; B,D=Cu 16-55

16-10 45° A=Al; B=Ch; C=Cu 16-56

16-13 90° A=Con; B=Cu 16-57

16-10 A=Al; B=Cu; C=Ch 16-58

16-10 A=Con; B,C=Cu 16-59 80 - - 280 A 16-60

16-13 A=Al; B=Ch 16-62

16-11 A=Con; B=Cu 18A31 18-1 110° A(B,C,F,G) 18-1 70 145 215 290 A(B,C,F,G) 18-3 35 110 250 325 D 18-4 35 110 250 325 D 18-5 80 110 250 280 D 18-6 - - - - D 18-7 - - - - B 18-8 70 - - 290 A 18-9 80 110 250 280 I 18-10 - 120 240 - A 18-11 - 170 265 - A 18-12 80 - - 280 A 18-13 80 110 250 280 A 18-14 80 110 250 280 A 18-15

- 120 140 - A,C=Ir; B,D=Con 18-16 - - - - C 18-17 18-9 100° I 18-18 18-9 250° I 18-19 80 120 240 - A 18-20 90 180 270 - A 18-22 70 145 215 290 D 18-23 18-1 100° A(B,C,F,G) 18-24 18-1 250° A(B,C,F,G) 18-25 18-3 100° D 18-26 18-3 250° D NOTE: 16S contacts are used in shell sizes 8S, 10S, 10SL, 12S, 14S & 16S Read Less 18-27 Through 20-21

Contacts Sizes Layout 97 Series AIT Series AIB/GT VG95234 MS3450 Total 20 16 12 8 4 0 18-27

3 1 2 18-28

3 1 2 18-29

5 5 18-30

5 5 18-31

5 5 18-420

1 HV 1 HV 18-51

6 6 18-52

5 5 18-53

6 6 18-54

4 4 18-56

10 10 18-57

6 6 18-59

6 6 18-60

5 5 18-61

6 6 18-62

6 6 18-63

4 4 18-65

6 6 18-66

10 10 18-67

6 6 18-68

5 5 18-69

10 10 18-70

5 5 18-71

4 4 18-72

4 4 18-73

7 5 2 18-74

6 6 20A9

9 9 20A16

13 13 20A37

4 4 20A48

19 19 20-2

1 1 20-3

3 3 20-4

4 4 20-6

3 3 20-7

8 8 20-8

6 4 2 20-9

8 7 1 20-11

13 13 20-12

2 1 1 20-14

5 3 2 20-15

7 7 20-16

9 7 2 20-17

6 1 5 20-18

9 6 3 20-19

3 3 20-20

4 3 1 20-21

9 8 1 **Socket only for MS3450 ^015 QPL not all configurations Degrees of Rotation Layout

W X Y Z Service Rating 18-27 18-5 100° D 18-28 18-5 250° D 18-29 90 180 270 - D 18-30 18-20 110° A 18-31 18-20 260° A 18-420 24 KVdc; 17KVac 18-51

18-12 A=Ir; B,E=Con.; D=Cu; C,F=Dummy 18-52

18-11 A=Ir; B=Con.; C=Ch; D=Al; F=Dummy 18-53

18-12 A,D=Ir; B,E=Con.; C,F=Dummy 18-54

18-15 A,C=Al; B,D=Ch. 18-56

18-1 45° A,C,E,G,I=Ir; B,D,F,H,J=Con. 18-57

18-12 45° A,C,E,=Al; B,D,F=Ch. 18-59

18-12 45° A,C=Ir; B,E,F=Con.; D=Cu. 18-60

18-11 45° A,D=Al; B,C=Ch.; E=Cu 18-61

18-12 A,C=Ir; B,D=Con.; E=Ch; F=Al. 18-62

18-12 A,B,C=Ir; D,E,F=Con. 18-63

18-15 A,C=Con; B,D=Cu 18-65

18-12 A=Ir; B=Con.; Balance=Cu 18-66

18-1 A,C,E,G,I=Cu; B,D,F,H,J=Con. 18-67

18-12 A,C,E=Cu; B,D,F=Con. 18-68

18-11 A,D=Al; B,C=Ch.; E=Cu. 18-69

18-1 A=Al; B=Ch.; Balance=Cu. 18-70

18-11 A=Ir; B=Con.; C=Ch; D=Al; E=Cu. 18-71

18-15 A=Con; Balance=Cu 18-72

18-15 D=Con; Balance=Cu 18-73

18-9 A=Al; D=Ch.; Balance=Cu. 18-74

18-12 A=Ch; B=Al.; D=Ir; E=Cu; F=Con. 20A9 - 110 250 - D(J), I(all others) 20A16 20-11 182° I 20A37 20-4 250° D 20A48 80 280 - - I 20-2 - - - - D 20-3 70 145 215 290 D 20-4 45 110 250 - D 20-6 70 145 215 290 D 20-7 80 110 250 280 A(B,C,F,G) 20-8 80 110 250 280 I 20-9 80 110 250 280 D(H). A(all others) 20-11 - - - - I 20-12 80 110 250 280 A 20-14 80 110 250 280 A 20-15 80 - - 280 A 20-16 80 110 250 280 A 20-17 90 180 270 - A 20-18 35 110 250 325 A 20-19 90 180 270 - A 20-20 80 110 250 280 A 20-21 35 110 250 325 A NOTE: 16S contacts are used in shell sizes 8S, 10S, 10SL, 12S, 14S & 16S Read Less 20-22 Through 22-13

Contacts Sizes Layout 97 Series AIT Series AIB/GT VG95234 MS3450 Total 20 16 12 8 4 0 20-22

6 3 3 20-23

2 2 20-24

4 2 2 20-25

13 13 20-26

19 19 20-27

14 14 20-29

17 17 20-30

13 13 20-32

8 8 20-33

11 11 20-51

3 3 20-52

4 4 20-56

8 8 20-57

7‡ 7‡ 20-58

10 5 5 20-59

3‡ 3‡ 20-60

8 8 20-61

17 17 20-62

7 7 20-64

14 14 20-65

14 14 20-66

6‡ 1 5‡ 20-67

9 7 2 20-68

8 8 20-69

14 14 20-70

17 17 20-71

17 17 20-74

17 17 20-75

7 7 20-77

9 7 2 20-79

8‡ 7 1‡ 20-80

14 14 20-81

14 14 20-82

17 17 22B22

4 4 22-1

2 2 22-2

3 3 22-4

4 2 2 22-5

6 4 2 22-6

3 1 2 22-7

1 1 22-8

2 2 22-9

3 3 22-10

4 4 22-11

2 2 22-12

5 3 2 22-13

5 1 4 Degrees of Rotation Layout

W X Y Z Service Rating 20-22 80 110 250 280 A 20-23 35 110 250 325 A 20-24 35 110 250 325 A 20-25 20-11 100° I 20-26 - 80 280 - A 20-27 35 110 250 325 A 20-29 80 - - 280 A 20-30 20-11 250° I 20-32 20-7 260° A(B,C,F,G) 20-33 - - - 280# A 20-51 - - - - A 20-52

20-4 315° A=Ir; B=Con.; C=Ch.; D=Al 20-56

20-7 45° A,B,G,H=Ir.; C,D,E,F=Con. 20-57 - - - - A 20-58 - - - - A 20-59 - - - - A 20-60

20-7 45° D=Ch; E=Al; Balance=Cu. 20-61

20-29 45° A,B,M=Cu; Balance=Con. 20-62

20-15 80° A,C,E=Al; B,D,F=Ch; G=Cu. 20-64

20-7 A=Al; C=Ch; Balance=Cu. 20-65

20-27 A,B,C,D,E,F,G=Ir; H,I,J,K,L,M,N=Con. 20-66 - - - - A 20-67

20-16 H=Al; I=Ch; Balance=Cu. 20-68

20-7 A,B,G,H=Con; C,D,E,F=Cu. 20-69

20-27 A,B,C,D,E,F,G=Cu; H,I,J,K,L,M,N=Con. 20-70

20-29 A,C,E,G,J,L,N,R,T=Ir; B,D,F,H,K,M,P,S=Con. 20-71

20-29 S=Al; R=Ch; Balance=Cu. 20-74

20-29 A,C,E,G,J,L,N,R=Ir; B,D,F,H,K,M,P,S=Con; T=Cu 20-75

20-15 G=Al; Balance=Ch. 20-77

20-16 A=Con; Balance=Cu. 20-79 - - - - D(H); A(all others) 20-80

20-27 A,C,E,G,I,K,M=Cu; B,D,F,H,J,L,N=Con. 20-81

20-27 A,C,E,G,I,K,M=Ch; B,D,F,H,J,L,N=Al. 20-82

20-29 A,C,E,G,J,L,N,R=Al; B,D,F,H,K,M,P,S=Ch; T=Cu 22B22 - 110 250 - A 22-1 35 110 250 325 D 22-2 70 145 215 290 D 22-4 35 110 250 325 A 22-5 35 110 250 325 D 22-6 80 110 250 280 D 22-7 - - - - E 22-8 35 110 250 325 E 22-9 70 145 215 290 E 22-10 35 110 250 325 E 22-11 35 110 250 325 B 22-12 80 110 250 280 D 22-13 35 110 250 325 A(A-D) D(E) #Rotation commercial only, not MS-approved ‡Reduced contact crimp pot ^5015 QPL not all configurations **Socket only for MS3450 series ***Pin only for MS3450 series Read Less 22-14 Through 24-7

Contacts Sizes Layout 97 Series AIT Series AIB/GT VG95234 MS3450 Total 20 16 12 8 4 0 22-14

19 19 22-15

6 1 5 22-16

9 6 3 22-17

9 8 1 22-18

8 22-19

14 14 22-20

9 9 22-21

3 2 1 22-22

4 4 22-23

8 8 22-24

6 4 2 22-26

7 5 2 22-27

9 8 1 22-28

7 7 22-30

19 19 22-31

2 2 22-32

6 4 2 22-33

7 7 22-34

5 2 3 22-36

8 8 22-57

19 19 22-60

19 19 22-62

8 8 22-63

12 8 4 22-65

8* 8* 22-68

14 14 22-69

14 14 22-70

13 5 8 22-71

14 14 22-72

6 4 2 22-73

6 4 2 22-74

8 8 22-75

8 8 22-76

21 21 22-77

14 14 22-78

19 19 22-79

4 4 22-80

3* 3* 24A35

16 14 2 24-2

7 7 24-3

7 5 2 24-4

4 3 1 24-5

16 16 24-6

8 8 24-7

16 14 2 ^5015 QPL not all configurations Degrees of Rotation Layout

W X Y Z Service Rating 22-14 80 110 250 280 A 22-15 80 110 250 280 A(A-C,E,F) E(D) 22-16 80 110 250 280 A 22-17 80 110 250 280 D(A) A(all others) 22-18 80 110 250 280 A(C-E) 22-19 80 110 250 280 A 22-20 35 110 250 325 A 22-21 80 110 250 280 A 22-22 - 110 250 - A 22-23 35 - 250 - D(A-D); A(E-G) 22-24 80 110 250 280 D(C,D,E) A(A,B,F) 22-26 - - - - 1/8" spacing 22-27 80 - 250 280 D(J) A(all others) 22-28 80 - - 280 A 22-30 22-14 100° A 22-31 22-11 100° B 22-32 22-5 260° D 22-33 80 110 250 280 D(A-D) A(E-G) 22-34 80 110 250 280 D 22-36 90 - 270 - D(H); A(all others) 22-57

22-14 45° A,C,E,G,J,L,N,R=Ir; B,D,F,H,K,M,P,S=Con.; T,U,V=Cu 22-60

22-14 45° U=Al.; N=Ch; Balance=Cu. 22-62

22-23 60° A,B,F,G=Al.; C,D,E,H=Ch. 22-63 20 - - - A 22-65 - - - - D(H); A(all others) 22-68

22-19 45° A,C,E,G,J,L,M=Ir.; B,D,F,H,K,P,N=Con. 22-69

22-19 45° A,C,E,G,J,L,M=Cu.; B,D,F,H,K,P,N=Con. 22-70 - - - - A 22-71

22-14 V=Al.; U=Ch.; Balance=Cu. 22-72

22-5 B=Al.; E=Ch.; Balance=Cu. 22-73

22-5 E=Al.; B=Ch.; Balance=Cu. 22-74

22-23 A,C,E,G=Ir.; B,D,F,H=Con. 22-75

22-23 A=Al.; B,D,G,H=Cu.; C=Ch.; E=Ir.; F=Con. 22-76

W=Con.; Balance=Cu. 22-77

22-19 B,D,F,H,J,K,M,P=Cu.; A,E,L=Ir.; F=Con. 22-78

22-14 A,C,E,G,H,K,M,P,R,T=Con.; Balance=Cu. 22-79

22-10 A,C=Con.; B,D=Cu. 22-80 - - - - A 24A35 24-7 100° A 24-2 80 - - 280 D 24-3 80 110 250 280 D 24-4 80 110 250 280 D 24-5 80 110 250 280 A 24-6 80 110 250 280 D(A,G,H) 24-7 80 110 250 280 A #Rotation commercial only, not MS-approved ‡Reduced contact crimp pot ^5015 QPL not all configurations **Socket only for MS3450 series ***Pin only for MS3450 series Read Less 24-9 Through 28-7

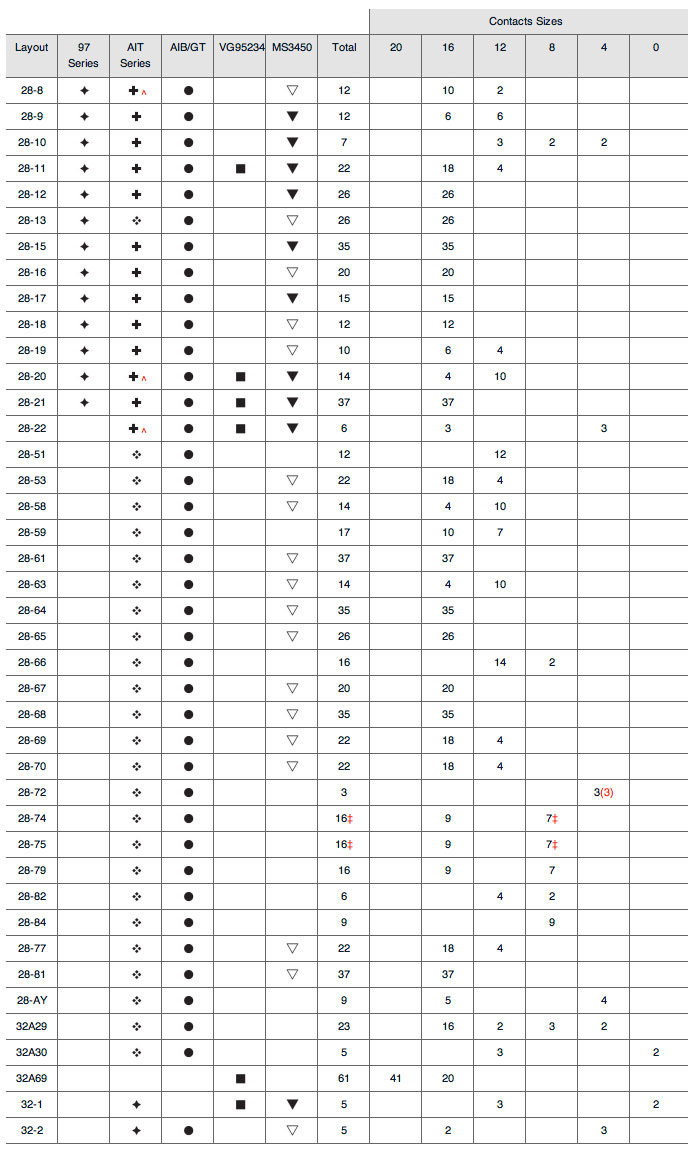

‡Reduced contact crimp ^5015 QPL not all configurations ( ) Number of contacts that are co-ax Read Less 28-8 Through 32-2

‡Reduced contact crimp ^5015 QPL not all configurations ( ) Number of contacts that are co-ax Read Less 32-3 Through 36-8

‡Reduced contact crimp ^5015 QPL not all configurations ( ) Number of contacts that are co-ax Read Less 36-9 Through 40-3

‡Reduced contact crimp ^5015 QPL not all configurations ( ) Number of contacts that are co-ax Read Less 40-4 Through 40-AV

‡Reduced contact crimp ^5015 QPL not all configurations ( ) Number of contacts that are co-ax Read Less STEP 8: CONTACTSTEP 8: SELECT CONTACT TYPE

S = Solder C = Crimp* * When using 'C' in part number, the connector is supplies with the standard size crimp contacts for its layout. Bolded part numbers on indicate crimp contact. Please call for connectors with reduced or enlarged crimp barrel contacts. Click here for post diameters and lengths. STEP 9: PLATINGSTEP 9: SELECT PLATING

Contacts Shell Plating Materials B30 = Gold 30u" Gold over Nickel 023 = Nickel (RoSH with crimp or 116 contacts) (Omit for standard neoprene) |

|

PIN & SOCKET CRIMP CONTACTSAMPHENOL AIB/GT SERIES PIN & SOCKET CRIMP CONTACTS

Pin Contact Socket Contact Wire Strip Length Wire Range

Part Number Part Number Wire Strip Wire Sealing Contact Size Wire Size AWG Silver Gold Silver Gold Inches Inches

16-18-20 12-14 14-16 18-20 20-22 22-24 AIC16S-16P* AIC16S-12P AIC16S-14P AIC16S-20P AIC16S-22P AIC16S-24P AIC16S- AIC16S- AIC16S- AIC16S- AIC16S- AIC16S- AIC16S-16S* AIC16S-12S AIC16S-14S AIC16S-20S AIC16S-22S AIC16S-24S AIC16S- AIC16S- AIC16S- AIC16S- AIC16S- AIC16S- C4 C3 C13 C14 C2 0.312 (7.9) .090-.118 (2.3-3.0) 16 16-18-20 12-14 14-16 18-20 20-22 20-24 22-24 AIC16-16P* AIC16-12P AIC16-14P AIC16-18P AIC16-20P AIC16-2024P AIC16-22P AIC16-16PG* AIC16-12PG AIC16-14PG AIC16-18PG AIC16-20PG AIC16-2024PG AIC16-22PG AIC16-16S* AIC16-12S AIC16-14S AIC16-18S AIC16-20S AIC16-2024S AIC16-22S AIC16-16SG* AIC16-12SG AIC16-14SG AIC16-18SG AIC16-20SG AIC16-2024SG AIC16-22SG - C4 C3 C13 C14 C36 C2 0.312 (7.9) .090-.118 (2.3-3.0) 12 12-14 12 High-Power 8-10 10-12 14-16 16-18 18-20 20-22 AIC12-12P* - AIC12-8P AIC12-10P AIC12-14P AIC12-16P AIC12-18P AIC12-20P AIC12-12PG* - AIC12-8PG AIC12-10PG AIC12-14PG AIC12-16PG AIC12-18PG AIC12-20PG AIC12-12S* AIC12-12SRAD AIC12-8S AIC12-10S AIC12-14S AIC12-16S AIC12-18S AIC12-20S AIC12-12SG* - AIC12-8SG AIC12-10SG AIC12-14SG AIC12-16SG AIC12-18SG AIC12-20SG C5 C8 C9 C7 C6 C40 0.312 (7.9) .126-.177 (3.2-4.5) 8 8 8 High-Power 10-12 12-14 AIC8-8P* - AIC8-10P AIC8-12P AIC8-8PG* - AIC8-10PG AIC8-12PG AIC8-8S* AIC8-8SRAD AIC8-10S AIC8-12S AIC8-8SG* - AIC8-10SG AIC8-12SG C10 C38 0.563 (14.3) .150-.256 (3.8-6.5) 4 4 4 High-Power 8 AIC4-4P* - AIC4-8P AIC4-4PG* - AIC4-8PG AIC4-4S* AIC4-4SRAD AIC4-8S AIC4-4SG* - AIC4-8SG C15 0.500 (12.7) .279-.366 (7.1-9.3) 0 0 0 High-Power 0-2 4 AIC0-0P* - AIC0-2P AIC0-4P AIC0-0PG* - AIC0-2PG AIC0-4PG AIC0-0S* AIC0-0SRAD AIC0-2S AIC0-4S AIC0-0SG* - AIC0-2SG AIC0-4SG C11 C12 0.750 (19.0) .394-.539 (10.0-13.7) *Bolded items are standard crimp contacts. Solder Thermocouple Contacts Contact Size Type Pins Sockets 16S† Alumel Chromel Iron Constantan 10-040799-02P* 10-040799-01P* 10-040799-03P* 10-040799-04P* 10-040799-02S* 10-040799-01S* 10-040799-03S* 10-040799-04S* 16 Alumel Chromel Iron Constantan 10-040799-12P* 10-040799-11P* 10-040799-13P* 10-040799-14P* 10-040799-12S* 10-040799-11S* 10-040799-13S* 10-040799-14S* 12 Alumel Chromel Iron Constantan 10-040799-42P* 10-040799-41P* 10-040799-43P* 10-040799-44P* 10-040799-42S* 10-040799-41S* 10-040799-43S* 10-040799-44S* Thermocouple Types: J = Iron-Constantan K = Alumel-Chromel T = Copper-Constantan E = Chromel-Constantan *Contact us for availability. † 16S contacts are used in 8S, 10S, 10SL, 12S, 14S & 16S connector sizes only. Accessories Tools

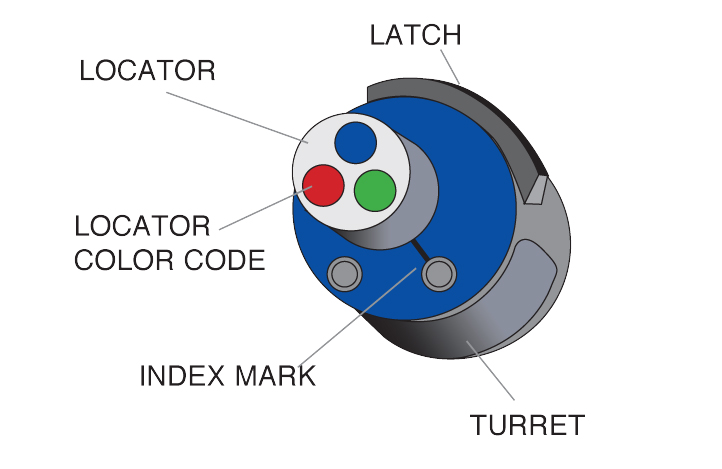

Contact Size Wire Hole Filler Color Crimp Tools Crimp Locator & Die Sets Locator Color Pilot Pin/Insertion Guide for Sockets Insertion Tool Extraction Tool

16

Pin-BlueSocket-Green

Yellow AF8-(hand) WA27F-(pneumatic) †† TH29-1 Green 10-242758-012 DAK168-12 DRK59 Kit with Multiple Tips

Red 400BHD Die Set - 10-242758-008 AIC8INS DRK59 Kit with Multiple Tips

Blue 400BHD Die Set - - AIC4INS AIC4EXT-P (Pin)

Yellow 400BHD Die Set - - AIC0INS AIC0EXT-P (Pin) All dimensions in inches (millimeters in parentheses) † 16S contacts are used in 8S, 10S, 10SL, 12S, 14S & 16S connector sizes only. †† Contact us for additional tool accessories. PIN & SOCKET CO-AX CONTACTSAMPHENOL AIB/GT SERIES PIN & SOCKET CO-AX CONTACTS

Pin Contact Socket Contact Wire Strip Length Wire Range Accessories

Part Number Part Number Wire Sealing Range Inches (MM) Co-ax Contact Co-ax Wire Size Silver Gold Silver Gold Wire Strip Lengths Inches (MM) Min. Max. Wire Hole Filler 12 RG161/U RG174A/U RG179B/U RG187A/U RG188A/U RG316/U RG178B/U RG196A/U 21-33034-1 - 21-33014-21 21-33048-1( ) 21-33130-1( ) 21-33014-22 21-33033-1 - 21-33013-21 21-33047-1( ) 21-33129-1 ( ) 21-33013-22 0.126 0.177 Yellow 8 RG58C/U RG141A/U RG303/U RG59B/U RG62A/U RG62B/U RG210/U RG161/U RG174A/U RG179B/U RG187A/U RG188A/U RG316/U RG180B/U RG195A/U RG140/U RG302/U RG55B/U RG142A/U RG142B/U RG223/U 21-33034-2(1) 21-33034-5(1) 21-33034-3(1) 21-33034-6 21-33034-8 21-33034-4 21-33014-1(5) 21-33016-5(3) 21-33130-2( ) 21-33014-5(5) 21-33016-2(3) 21-33130-5( ) 21-33064- 21-33014-3(5) 21-33016-1(3) 21-33130-3( ) 21-33064- 21-33014-6(5) 21-33048-3( ) 21-33130-6( ) 21-33014-8(5) 21-33033-8 21-33130-8( ) 21-33014-5(5) 21-33130-4( ) 21-33033-2(1) 21-33048-2( ) 21-33033-3(1) 21-33033-3(1) 21-33033-6 - 21-33033-4 21-33013-1(5) 21-33047-2() 21-33015-5(3) 21-33129-2( ) 21-33013-5(5) 21-33015-2(3) 21-33129-3( ) 21-33063- 21-33013-3(5) 21-33015-1(3) 21-33129-3( ) 21-33063- 21-33013-(6) 21-33047-3( ) 21-33129-6( ) 21-33013-8(5) 21-33129-8( ) 21-33013-5(5) 21-33129-4( ) 0.150 0.256 White 4 RG59B/U RG62A/U RG62B/U RG210/U RG212/U RG55B/U RG142A/U RG142B/U RG223/U - 21-33060- 21-33060- 31-33060- - 21-33059- 21-33059- 21-33059- 0.279 0.366 Blue ( ) Various platings available. Availability of co-ax contacts varies widely. Contact us for details. Tools

Co-ax Contact Size Co-ax Wire Size Hand Crimp Tool Hand Crimp Tool Use Locator Co-ax Clamp Nut Wrench 12 RG161/U RG174A/U RG179B/U RG187A/U RG188A/U RG316/U RG178B/U RG196A/U M22520/10-01 M22520/10-05 A B 11-8676-1 8 RG58C/U RG141A/U RG303/U RG59B/U RG62A/U RG62B/U RG210/U RG161/U RG174A/U RG179B/U RG187A/U RG188A/U RG316/U RG180B/U RG195A/U RG140/U RG302/U RG55B/U RG142A/U RG142B/U RG223/U M22520/10-01 M22520/5-01 M22520/10-01 M22520/10-07 M22520/5-45 M22520/10-05 M22520/10-07 B B A B A 11-8676-2 11-8676-3 11-8676-2 4 RG59B/U RG62A/U RG62B/U RG210/U RG212/U RG55B/U RG142A/U RG142B/U RG223/U M22520/5-01 M22520/5-01 M22520/10-01 M22520/5-45 M22520/5-39 M22520/10-07 B A A 11-8676-4 All dimensions in inches (millimeters in parentheses) CONNECTOR TOOLSAMPHENOL AIB/GT SERIES CONNECTOR TOOLS

TG70 Strap Wrench

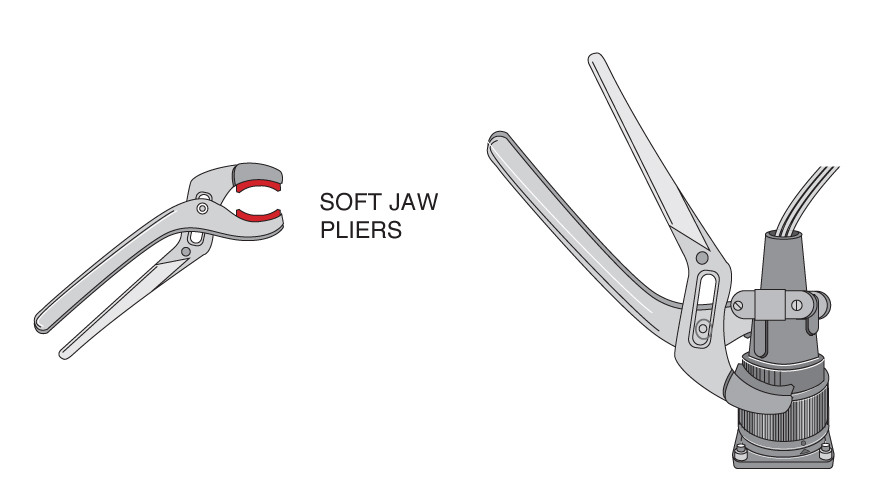

TG69P Non-Marring Adjustable Endbell Pliers for Field Service 600 Series Production System The 600 series is a complete system for the proper assembly and torquing of connector endbells. The system includes a bench-mounted or hand-held torque wrench, plug and receptacle holders, and a range of endbell tightening tools. When used together, these tools provide the user with consistent endbell installations. Each item is shipped with detailed assembly instructions.

Plug and Receptacle Holders

MIL-DTL-5015 For AIT/MS & AIB/GT Shell Size Receptacles Plugs 8/8S 600B005-8R 600B005-8P 10S/SL 600B005-10R 600B005-10P 12/12S 600B005-12R 600B005-12P 14/14S 600B005-14R 600B005-14P 16/16S 600B005-16R 600B005-16P 18 600B005-18R 600B005-18P 20 600B005-20R 600B005-20P 22 600B005-22R 600B005-22P 24 600B005-24R 600B005-24P 28 600B005-28R 600B005-28P 32 600B005-32R 600B005-32P 36 600B005-36R 600B005-36P TORQUE VALUES

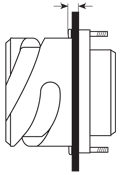

IMPORTANT NOTE: If barrel/shell has three threads or less, torque to 30 to 35 inch/Lbs (3.4 to 4.0 NM) per L-725-2. Size In./Lb. Max. 10SL 26 14S 44 16 50 16S 50 18 55 20 65 22 85 24 90 28 114 32 120 36 153 40 170 Rotations Pin Socket W = G W = H X = I X = J Y = K Y = L Z = M Z = N |

|

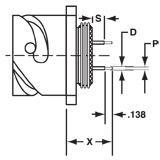

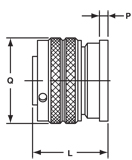

PRINTED CIRCUIT CONTACTSAMPHENOL AIB/GT SERIES PRINTED CIRCUIT CONTACTS

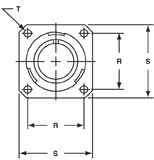

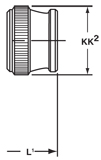

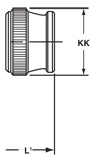

H Series Shell Size S X 10SL 0.188 (4.78) 0.567 (14.40) 14S 0.188 (4.78) 0.567 (14.40) 16S 0.188 (4.78) 0.567 (14.40) 16 0.188 (4.78) .622 (15.80) 18 0.188 (4.78) .622 (15.80) 20 0.188 (4.78) .622 (15.80) 22 0.188 (4.78) .622 (15.80) 24 0.188 (4.78) .622 (15.80) 28 0.188 (4.78) .657 (16.69) 32 0.188 (4.78) .720 (18.29) 32 0.188 (4.78) .720 (18.29) 36 0.188 (4.78) .720 (18.29) 40 0.188 (4.78) .720 (18.29) Contact Size D P 12 .134 (3.4) .070 (1.78) 16 .063 (1.6) .030 (0.76) All dimensions in inches (millimeters in parentheses) RECEPTACLESAMPHENOL AIB/GT SERIES STYLE 0, 2, 20, 30 RECEPTACLES

2

0,20,30

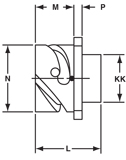

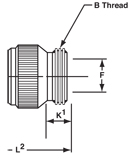

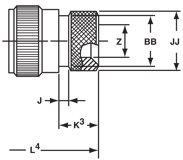

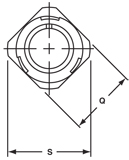

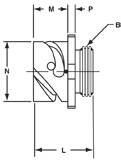

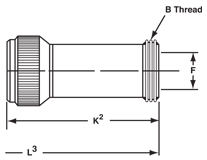

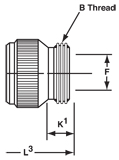

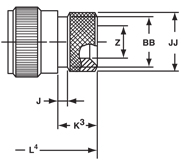

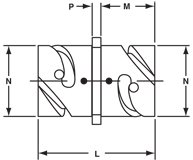

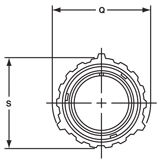

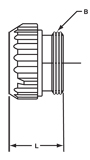

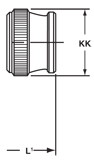

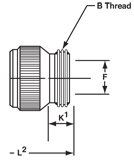

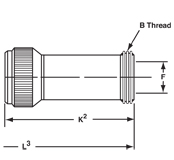

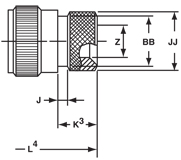

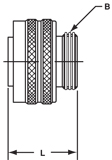

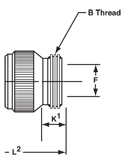

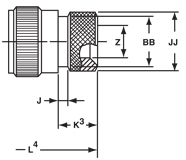

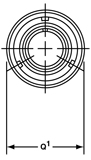

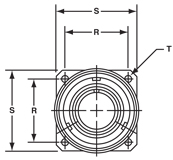

0, 20, 30 RV Shell Size M +.016- N +.000- P ± .008 (±0.2) R ± .004 (±0.1) S ± .012 (±0.3) T +.004- KK Max. B Thread Class 2A L + .012 (+ 0.3) L1 Max. KK2 Max. 10SL .717 .717 .110 .717 1.000 .126 .626 .6250-24 UNEF 1.087 1.890 .787 14S .717 .969 .126 .906 1.181 .126 .756 .7500-20 UNEF 1.087 1.890 .945 (24.0) 16S .717 1.079 .126 .969 1.280 .126 .882 .8750-20 UNEF 1.087 1.890 1.024 16 .846 1.079 .126 .969 1.280 .126 .882 .8750-20 UNEF 1.331 2.205 1.024 18 .907 1.213 .157 1.063 1.378 .126 1.008 1.0000-20 UNEF 1.331 2.244 1.161 20 .907 1.346 .157 1.157 1.496 .126 1.142 1.1250-18 UNEF 1.331 2.244 1.299 22 .907 1.472 .157 1.252 1.614 .126 1.268 1.2500-18 UNEF 1.331 2.244 1.417 24 .907 1.610 .157 1.374 1.752 .146 1.390 1.3750-18 UNEF 1.331 2.244 1.575 28 .947 1.839 .157 1.563 2.000 .146 1.630 1.6250-18 UNEF 1.406 2.244 1.811 32 .947 2.102 .157 1.752 2.244 .169 1.882 1.8750-16 UN 1.469 2.362 2.028 36 .947 2.346 .157 1.937 2.500 .169 2.063 2.0625-16 UN 1.469 2.362 2.283 40 .947 2.579 .157 2.185 2.752 .169 2.323 2.3125-16 UN 1.469 (37.3) 2.362 2.539 All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES STYLE 0, 20, 30 RECEPTACLES

Shell Size B Thread Class 2A F Min. K1 Min. K2 Min. L2 Max. L3 Max. J ± .008 K3 + .020 L4 Max. Z Max. BB Max. JJ + .008 10SL .6250-24 UNEF .409 .374 2.110 1.969 3.197 .138 .461 1.969 .303 .524 .610 14S .7500-20 UNEF .520 .374 2.145 1.969 3.232 .138 .461 1.969 .417 .669 .752 16S .8750-20 UNEF .638 .374 2.145 1.969 3.232 .138 .461 1.969 .531 .862 .941 16 .8750-20 UNEF .638 .374 2.240 2.362 3.571 .138 .453 2.362 .531 .862 .941 18 1.0000-20 UNEF .756 .374 2.315 2.362 3.646 .138 .453 2.362 .575 .862 .941 20 1.1875-18 UNEF .867 .374 2.300 2.362 3.631 .138 .500 2.559 .736 1.031 1.165 22 1.1875-18 UNEF .965 .374 2.305 2.362 3.636 .138 .500 2.559 .819 1.031 1.165 24 1.4375-18 UNEF 1.094 .374 2.320 2.560 3.651 (92.7) .138 .500 2.559 .969 1.358 1.488 28 1.4375-18 UNEF 1.228 .374 2.490 2.560 3.896 (99.0) .138 .500 2.559 1.063 1.358 1.488 32 1.7500-18 UNS 1.488 .433 2.635 2.560 4.104 .138 .598 2.756 1.311 1.717 1.882 36 2.0000-18 UNS 1.780 .465 2.680 3.150 4.149 .138 .598 3.150 1.516 1.717 1.882 40 2.2500-16 UN 2.016 .465 2.680 3.150 4.149 .138 .610 3.150 1.898 2.071 2.276 All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES STYLE 1 CABLE RECEPTACLE

Shell Size M +.016 -.000 N +.000 -.006 P ± .008 Q ± .008 S Max. B Thread Class 2A L + .012 L1 Max. KK Max. 10SL .717 (18.2) .717 (18.2) .110 (2.8) .811 (20.6) .992 (25.2) .6250-24 UNEF 1.087 (27.6) 1.890 (48.0) .787 (20.0) 14S .717 (18.2) .969 (24.6) .126 (3.2) 1.000 (25.4) 1.173 (29.8) .7500-20 UNEF 1.087 (27.6) 1.890 (48.0) .945 (20.0) 16S .717 (18.2) 1.079 (27.4) .126 (3.2) 1.126 (28.6) 1.272 (32.3) .8750-20 UNEF 1.087 (27.6) 1.890 (48.0) 1.024 (26.0) 16 .846 (21.5) 1.079 (27.4) .126 (3.2) 1.126 (28.6) 1.272 (32.3) .8750-20 UNEF 1.331 (33.8) 2.205 (56.0) 1.024 (26.0) 18 .907 (23.0) 1.213 (30.8) .157 (4.0) 1.248 (31.7) 1.370 (34.8) 1.0000-20 UNEF 1.331 (33.8) 2.244 (57.0) 1.161 (29.5) 20 .907 (23.0) 1.346 (34.2) .157 (4.0) 1.374 (34.9) 1.488 (37.8) 1.1250-18 UNEF 1.331 (33.8) 2.244 (57.0) 1.299 (33.0) 22 .907 (23.0) 1.472 (37.4) .157 (4.0) 1.500 (38.1) 1.618 (41.1) 1.2500-18 UNEF 1.331 (33.8) 2.244 (57.0) 1.417 (36.0) 28 .947 (24.1) 1.839 (46.7) .157 (4.0) 1.874 (47.6) 2.004 (50.9) 1.6250-18 UNEF 1.406 (35.7) 2.244 (57.0) 1.811 (46.0) 32 .947 (24.1) 2.102 (53.4) .157 (4.0) 2.126 (54.0) 2.248 (57.1) 1.8750-16 UN 1.469 (37.3) 2.362 (60.0) 2.028 (51.5) 36 .947 (24.1) 2.346 (59.6) .157 (4.0) 2.386 (60.6) 2.504 (63.6) 2.0625-16 UN 1.469 (37.3) 2.362 (60.0) 2.283 (58.0) 40 .947 (24.1) 2.579 (65.5) .157 (4.0) 2.618 (66.5) 2.756 (70.0) 2.3125-16 UN 1.469 (37.3) 2.362 (60.0) 2.539 (64.5) All dimensions in inches (millimeters in parentheses)

Shell Size B Thread Class 2A F Min. K1 Min. K2 Max. L3 Max. L2 Max. J ± .008 K3 + .020 L4 Max. Z Min. BB Max. JJ + .008 10SL .6250-24 UNEF .409 .374 2.110 1.969 3.197 .138 .461 1.969 .303 .524 .610 14S .7500-20 UNEF .520 .374 2.145 1.969 3.232 .138 .461 1.969 .417 .669 .752 16S .8750-20 UNEF .638 .374 2.145 1.969 3.232 .138 .461 1.969 .531 .862 .941 16 .8750-20 UNEF .638 .374 2.240 2.362 3.571 .138 .453 2.362 .531 .862 .941 18 1.0000-20 UNEF .756 .374 2.315 2.362 3.646 .138 .453 2.362 .575 .862 .941 20 1.1875-18 UNEF .867 .374 2.300 2.362 3.631 .138 .500 2.559 .736 1.031 1.165 22 1.1875-18 UNEF .965 .374 2.305 2.362 3.636 .138 .500 2.559 .819 1.031 1.165 24 1.4375-18 UNEF 1.094 .374 2.320 2.560 3.651 .138 .500 2.559 .969 1.358 1.488 28 1.4375-18 UNEF 1.228 .374 2.490 2.560 3.896 .138 .500 2.559 1.063 1.358 1.488 32 1.7500-18 UNS 1.488 .433 2.635 2.560 4.104 .138 .598 2.756 1.311 1.717 1.882 36 2.0000-18 UNS 1.780 .465 2.680 3.150 4.149 .138 .598 3.150 1.516 1.717 1.882 40 2.2500-16 UN 2.016 .465 2.680 3.150 4.149 .138 .610 3.150 1.898 2.071 2.276 All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES STYLE TB THRU-BULKHEAD RECEPTACLE

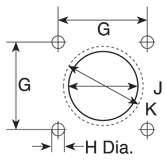

Shell Size L Max. M +.016-.000 N +.000-.006 P ±.008 R ±.004 S ±.012 T +.004 -.000 10SL 1.488 (37.7) .717 (18.2) .717 (18.2) .110 (2.8) .717 (18.2) 1.000 (25.4) .126 (3.2) 14S 1.488 (37.7) .717 (18.2) .969 (24.6) .126 (3.2) .906 (23.0) 1.181 (30.0) .126 (3.2) 16S 1.488 (37.7) .717 (18.2) 1.079 (24.6) .126 (3.2) .969 (23.0) 1.280 (30.0) .126 (3.2) 16 2.049 (52.0) .846 (21.5) 1.079 (24.6) .126 (3.2) .969 (23.0) 1.280 (30.0) .126 (3.2) 18 2.049 (52.0) .907 (23.0) 1.213 (30.8) .157 (4.0) 1.063 (27.0) 1.378 (35.0) .126 (3.2) 20 2.049 (52.0) .907 (23.0) 1.346 (34.2) .157 (4.0) 1.157 (29.4) 1.496 (38.0) .126 (3.2) 22 2.049 (52.0) .907 (23.0) 1.472 (37.4) .157 (4.0) 1.252 (31.8) 1.614 (41.0) .126 (3.2) 24 2.049 (52.0) .907 (23.0) 1.610 (40.9) .157 (4.0) 1.374 (34.9) 1.752 (44.5) .146 (3.7) 28 2.049 (52.0) .947 (24.0) 1.839 (46.7) .157 (4.0) 1.563 (39.7) 2.000 (50.8) .146 (3.7) 32 2.049 (52.0) .947 (24.0) 2.102 (53.4) .157 (4.0) 1.752 (44.5) 2.244 (57.0) .169 (4.3) 36 2.049 (52.0) .947 (24.0) 2.346 (59.6) .157 (4.0) 1.937 (49.2) 2.500 (63.5) .169 (4.3) 40 2.049 (52.0) .947 (24.0) 2.579 (65.5) .157 (4.0) 2.185 (55.5) 2.752 (69.9) .169 (4.3) All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES STYLE 7, 70 JAM NUT RECEPTACLES

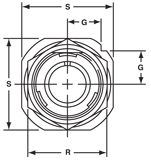

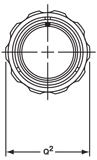

J Wall Thickness Shell Size B Thread Class 2A G ±.012 Min. Max. L ± .010 M ± .012 N +.000 P ± .007 R ± .016 S ± .12 BB Thread Class 2A 10SL .8750-20 UNEF .441 .094 .205 1.425 .965 .717 .157 1.062 1.252 .6250-24 UNEF 14S 1.1250-18 UNEF .575 .094 .295 1.531 1.055 .969 .189 1.312 1.626 .7500-20 UNEF 16S 1.2500-18 UNEF .618 .094 .295 1.531 1.055 1.079 .189 1.500 1.748 .8750-20 UNEF 16 1.2500-18 UNEF .618 .094 .295 1.909 1.264 1.079 .189 1.500 1.748 .8750-20 UNEF 18 1.3750-18 UNEF .661 .094 .354 1.941 1.327 1.213 .189 1.562 1.874 1.0000-20 UNEF 20 1.5000-18 UNEF .709 .094 .358 1.941 1.327 1.346 .189 1.750 2.000 1.1250-18 UNEF 22 1.6250-18 UNEF .795 .094 .358 1.941 1.327 1.472 .189 2.000 2.134 1.2500-18 UNEF 24 1.7500-18 UNEF .795 .094 .358 1.953 1.327 1.610 .189 2.000 2.252 1.3750-18 UNEF 28 2.0000-18 UNS .886 .094 .394 2.043 1.386 1.839 .220 2.188 2.500 1.6250-18 UNEF 32 2.2500-16 UN .972 .094 .394 2.043 1.386 2.102 .220 2.438 2.748 1.8750-16 UN 36 2.5000-16 UN 1.059 .094 .327 2.043 1.386 2.346 .220 2.812 3.000 2.0625-16 UN 40 2.7500-16 UN 1.165 .094 .327 2.043 1.386 2.579 .220 2.953 3.248 2.3125-16 UN All dimensions in inches (millimeters in parentheses) PLUGSAMPHENOL AIB/GT SERIES STYLE 4 RUBBER-COVERED PLUGS

Shell Size Q Max. S Max. B Thread Class 2A L + .012 (+ 0.3) L1 Max. KK Max 10SL 1.319 (33.5) 1.122 (28.5) .6250-24 UNEF 1.087 (27.6) 1.417 (36.0) .787 (20.0) 18 1.929 (49.0) 1.713 (43.5) 1.0000-20 UNEF 1.331 (33.8) 1.929 (49.0) 1.161 (29.5) 20 2.028 (51.5) 1.811 (46.0) 1.1250-18 UNEF 1.331 (33.8) 1.969 (50.0) 1.299 (33.0) 22 2.224 (56.5) 1.988 (50.5) 1.2500-18 UNEF 1.331 (33.8) 1.969 (50.0) 1.417 (36.0) 24 2.362 (60.0) 2.126 (54.0) 1.3750-18 UNEF 1.331 (33.8) 2.008 (51.0) 1.575 (40.0) 28 2.638 (67.0) 2.402 (61.0) 1.6250-18 UNEF 1.406 (35.7) 2.008 (51.0) 1.811 (46.0) 32 2.992 (76.0) 2.661 (67.6) 1.8750-16 UN 1.469 (37.3) 2.087 (53.0) 2.028 (51.5) 36 3.240 (82.3) 2.925 (74.3) 2.0625-16 UN 1.469 (37.3) 2.106 (53.5) 2.283 (58.0) 40 3.465 (88.0) 3.150 (80.0) 2.3125-16 UN 1.469 (37.3) 2.126 (54.0) 2.539 (64.5) All dimensions in inches (millimeters in parentheses)

F

L

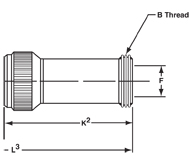

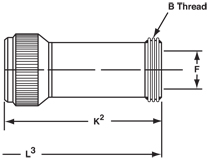

G Shell Size B Thread Class 2A F Min. K1 Min. K2 Min. L2 Max. L3 Max. J ± .008 K3 + .020 L4 Max. Z Min. BB Max. JJ + .008 10SL .6250-24 UNEF .409 .374 2.110 1.969 3.197 (81.2) .138 .461 1.969 .303 .524 .610 18 1.0000-20 UNEF .756 .374 2.315 2.362 3.646 .138 .453 2.362 .575 .862 .941 20 1.1875-18 UNEF .867 .374 2.300 2.362 3.631 .138 .500 2.559 .736 1.031 1.165 22 1.1875-18 UNEF .965 .374 2.305 2.362 3.636 .138 .500 2.559 .819 1.031 1.165 24 1.4375-18 UNEF 1.094 .374 2.320 2.560 3.651 .138 .500 2.559 .969 1.358 1.488 28 1.4375-18 UNEF 1.228 .374 2.490 2.560 3.896 .138 .500 2.559 1.063 1.358 1.488 32 1.7500-18 UNS 1.488 .433 2.635 2.560 4.104 .138 .598 2.756 1.311 1.717 (43.6) 1.882 36 2.0000-18 UNS 1.780 .465 2.680 3.150 4.149 .138 .598 3.150 1.516 1.717 1.882 40 2.2500-16 UN 2.016 .465 2.680 3.150 4.149 .138 .610 3.150 1.898 2.071 2.276 All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES STYLE 6, 6HD PLUGS

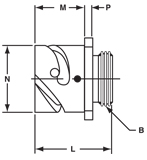

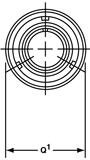

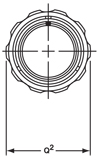

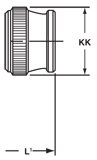

Shell Size Q1 Max. Q2 Max. B Thread Class 2A L + .012 (+ 0.3) L1 Max. KK Max. 10SL .898 (22.8) 1.007 (25.5) .6250-24 UNEF 1.087 (27.6) 1.417 (36.0) .787 (20.0) 14S 1.150 (29.2) 1.259 (31.9) .7500-20 UNEF 1.087 (27.6) 1.437 (36.5) .945 (24.0) 16S 1.260 (32.0) 1.410 (35.8) .8750-20 UNEF 1.087 (27.6) 1.437 (36.5) 1.024 (26.0) 16 1.260 (32.0) 1.410 (35.8) .8750-20 UNEF 1.331 (33.8) 1.929 (49.0) 1.024 (26.0) 18 1.437 (36.5) 1.547 (39.2) 1.0000-20 UNEF 1.331 (33.8) 1.929 (49.0) 1.161 (29.5) 20 1.571 (39.9) 1.681 (42.6) 1.1250-18 UNEF 1.331 (33.8) 1.969 (50.0) 1.299 (33.0) 22 1.697 (43.1) 1.847 (46.9) 1.2500-18 UNEF 1.331 (33.8) 1.969 (50.0) 1.417 (36.0) 24 1.835 (46.6) 1.965 (49.9) 1.3750-18 UNEF 1.331 (33.8) 2.008 (51.0) 1.543 (39.2) 28 2.102 (53.4) 2.222 (56.4) 1.6250-18 UNEF 1.406 (35.7) 2.008 (51.0) 1.811 (46.0) 32 2.366 (60.1) 2.482 (63.0) 1.8750-16 UN 1.469 (37.3) 2.087 (53.0) 2.028 (51.5) 36 2.610 (66.3) 2.721 (69.1) 2.0625-16 UN 1.469 (37.3) 2.106 (53.5) 2.283 (58.0) 40 2.850 (72.4) 2.953 (75.0) 2.3125-16 UN 1.469 (37.3) 2.126 (54.0) 2.539 (64.5) All dimensions in inches (millimeters in parentheses)

Shell Size B Thread Class 2A F Min. K1 Min. K2 Min. L2 Max. L3 Max. J ± .008 K3 + .020 L4 Max. Z Min. BB Max. JJ + .008 10SL .6250-24 UNEF .409 .374 2.110 1.969 3.197 (81.2) .138 .461 1.969 .303 .524 .610 14S .7500-20 UNEF .520 .374 2.145 1.969 3.232 .138 .461 1.969 .417 .669 .752 16S .8750-20 UNEF .638 .374 2.145 1.969 3.232 .138 .461 1.969 .531 .862 .941 16 .8750-20 UNEF .638 .374 2.240 2.362 3.571 .138 .453 2.362 .531 .862 .941 18 1.0000-20 UNEF .756 .374 2.315 2.362 3.646 .138 .453 2.362 .575 .862 .941 20 1.1875-18 UNEF .867 .374 2.300 2.362 3.631 .138 .500 2.559 .736 1.031 1.165 22 1.1875-18 UNEF .965 .374 2.305 2.362 3.636 .138 .500 2.559 .819 1.031 1.165 24 1.4375-18 UNEF 1.094 .374 2.320 2.560 3.651 .138 .500 2.559 .969 1.358 1.488 28 1.4375-18 UNEF 1.228 .374 2.490 2.560 3.896 .138 .500 2.559 1.063 1.358 1.488 32 1.7500-18 UNS 1.488 .433 2.635 2.560 4.104 .138 .598 2.756 1.311 1.717 1.882 36 2.0000-18 UNS 1.780 .465 2.680 3.150 4.149 .138 .598 3.150 1.516 1.717 1.882 40 2.2500-16 UN 2.016 .465 2.680 3.150 4.149 .138 .610 3.150 1.898 2.071 2.276 All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES PLUG STYLE 6, 6HD RIGHT ANGLE

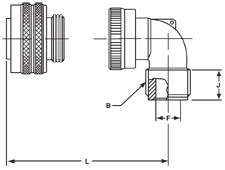

Shell Size Q1 Max. Q2 Max. B Thread Class 2A F Max. J Min. K Max. L Max. 10SL .898 (22.8) 1.007 (25.5) .6250-24 UNEF .337 (8.5) .370 (9.4) 1.181 (30.0) 1.772 (45.0) 14S 1.150 (29.2) 1.259 (31.9) .7500-20 UNEF .462 (11.7) .370 (9.4) 1.181 (30.0) 1.850 (47.0) 16S 1.260 (32.0) 1.410 (35.8) .8750-20 UNEF .587 (14.9) .370 (9.4) 1.181 (30.0) 1.890 (48.0) 16 1.260 (32.0) 1.410 (35.8) .8750-20 UNEF .587 (14.9) .370 (9.4) 1.181 (30.0) 2.244 (57.0) 18 1.437 (36.5) 1.547 (39.2) 1.0000-20 UNEF .685 (17.4) .370 (9.4) 1.378 (35.0) 2.283 (58.0) 20 1.571 (39.9) 1.681 (42.6) 1.1875-18 UNEF .810 (20.5) .370 (9.4) 1.378 (35.0) 2.402 (61.0) 22 1.697 (43.1) 1.847 (46.9) 1.1875-18 UNEF .915 (23.2) .370 (9.4) 1.378 (35.0) 2.402 (61.0) 24 1.835 (46.6) 1.965 (49.9) 1.4375-18 UNEF 1.025 (26.0) .370 (9.4) 1.575 (40.0) 2.598 (66.0) 28 2.102 (53.4) 2.222 (56.4) 1.4375-18 UNEF 1.139 (28.9) .370 (9.4) 1.575 (40.0) 2.598 (66.0) 32 2.366 (60.1) 2.482 (63.0) 1.7500-18 UNS 1.447 (36.7) .433 (11.0) 1.772 (45.0) 2.835 (72.0) 36 2.610 (66.3) 2.721 (69.1) 2.0000-18 UNS 1.687 (42.8) .496 (12.6) 1.969 (50.0) 2.953 (75.0) 40 2.850 (72.4) 2.953 (75.0) 2.2500-16 UN 1.923 (48.8) .496 (12.6) 2.165 (55.1) 3.071 (78.0) All dimensions in inches (millimeters in parentheses) AMPHENOL AIB/GT SERIES 6B PANEL PLUG

Shell Size L Approx. Q Max. P ±.008 (±0.2) R ±.004 (±0.1) S ± .012 (±0.3) T +.004-.000 (+0.1-0.0) 10SL 1.087 (27.6) .898 (22.8) .110 (2.8) .717 (18.2) 1.000 (25.4) .126 (3.2) 14S 1.091 (27.7) 1.150 (29.2) .126 (3.2) .906 (23.0) 1.181 (30.0) .126 (3.2) 16S 1.091 (27.7) 1.260 (32.0) .126 (3.2) .969 (24.6) 1.280 (32.5) .126 (3.2) 16 1.469 (37.3) 1.260 (32.0) .126 (3.2) .969 (24.6) 1.280 (32.5) .126 (3.2) 18 1.500 (38.1) 1.437 (36.5) .157 (4.0) 1.063 (27.0) 1.378 (35.0) .126 (3.2) 20 1.500 (38.1) 1.571 (39.9) .157 (4.0) 1.157 (29.4) 1.496 (38.0) .126 (3.2) 22 1.500 (38.1) 1.697 (43.1) .157 (4.0) 1.252 (31.8) 1.614 (41.0) .126 (3.2) 24 1.598 (40.6) 1.835 (46.6) .157 (4.0) 1.374 (34.9) 1.752 (44.5) .146 (3.7) 28 1.626 (41.3) 2.102 (53.4) .157 (4.0) 1.563 (39.7) 2.000 (50.8) .146 (3.7) 32 1.764 (44.8) 2.366 (60.1) .157 (4.0) 1.752 (44.5) 2.244 (57.0) .169 (4.3) 36 1.764 (44.8) 2.610 (66.3) .157 (4.0) 1.937 (49.2) 2.500 (63.5) .169 (4.3) 40 1.764 (44.8) 2.850 (72.4) .157 (4.0) 2.185 (55.5) 2.752 (69.9) .169 (4.3) All dimensions in inches (millimeters in parentheses) CUTOUTS & THICKNESSAMPHENOL AIB/GT SERIES PANEL CUTOUTS

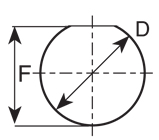

Style 0, 2, 20, 30, TB Flange Shell Size G (TP) Mounting Hole J Front K Rear 10SL 0.717 (18.2) 0.126 (3.2) 0.688 (17.5) 0.750 (19.1) 14S 0.906 (23.0) 0.126 (3.2) 0.813 (20.7) 1.000 (25.4) 16S 0.969 (24.6) 0.126 (3.2) 0.938 (23.8) 1.125 (28.6) 16 0.969 (24.6) 0.126 (3.2) 0.938 (23.8) 1.125 (28.6) 18 1.063 (27.0) 0.126 (3.2) 1.063 (27.0) 1.250 (26.7) 20 1.157 (29.4) 0.126 (3.2) 1.188 (30.2) 1.375 (35.0) 22 1.252 (31.8) 0.126 (3.2) 1.313 (33.4) 1.500 (38.1) 24 1.374 (34.9) 0.146 (3.7) 1.438 (36.5) 1.625 (41.3) 28 1.563 (39.7) 0.146 (3.7) 1.688 (42.9) 1.875 (47.6) 32 1.752 (44.5) 0.169 (4.3) 1.938 (49.2) 2.125 (54.0) 36 1.937 (49.2) 0.169 (4.3) 2.125 (54.0) 2.375 (60.3) 40 2.185 (55.5) 0.169 (4.3) 2.375 (60.3) 2.625 (66.7)  7/70 Panel Cutout Shell Size F-Flat D-Diameter 10SL 0.830 (21.1) 0.875 (22.2) 14S 1.080 (27.4) 1.125 (28.6) 16S/16 1.210 (30.7) 1.250 (31.7) 18 1.320 (33.5) 1.375 (34.9) 20 1.450 (36.8) 1.500 (38.1) 22 1.570 (39.9) 1.625 (41.3) 24 1.700 (43.2) 1.750 (44.5) 28 1.950 (49.5) 2.000 (50.8) 32 2.200 (55.9) 2.250 (57.2) 36 2.450 (62.2) 2.500 (63.5) 40 2.700 (68.6) 2.750 (69.9) AMPHENOL AIB/GT SERIES PANEL THICKNESS

Shell Size Rear Mount 10SL .303 (7.70) 14S .303 (7.70) 16S .303 (7.70) 16 .242 (6.15) 18 .303 (7.70) 20 .303 (7.70) 22 .303 (7.70) 24 .303 (7.70) 28 .343 (8.70) 32 .309 (7.85) 36 .309 (7.85) 40 .309 (7.85) All dimensions in inches (millimeters in parentheses) |

|

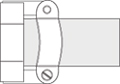

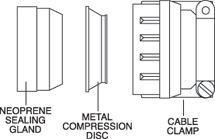

MS3057-AAMPHENOL AIB/GT SERIES M3057-A CABLE CLAMP

Standard MS3057 cable clamps have dual-clamping action to provide a balanced, positive hold on the wires and greatly reduce moisture transmission. This cable clamp accepts MS3420 bushings. MS3420 bushings can be nested to reduce the inside diameter to more closely match the diameter of the cable or wire bundle. Standard Clamp Standard Clamp and Telescopic Bushing Shell Size Thread Class 2B Low-Cost Cast Zinc Aluminum W/ Brass Screws Aluminum W/ Stainless Steel Screws Maximum Cable Diameter Inch (MM) Zinc With Low-Cost Bushing Included Bushing ID Inch (MM) 10SL 5/8-24UNEF 97-3057-1004** MS3057-4A M85049/41-4A 0.312 (7.92) 97-3057-1004-1 MS3420-4 0.220 (5.6) 14S 3/4-20UNEF 97-3057-1007** MS3057-6A M85049/41-6A 0.438 (11.10) 97-3057-1007-1 MS3420-6 0.312 (7.9) 16/16S 7/8-20UNEF 97-3057-1008** MS3057-8A M85049/41-8A 0.562 (14.27) 97-3057-1008-1 MS3420-8 0.437 (11.1) 18 1-20UNEF 97-3057-1010** MS3057-10A M85049/41-10A 0.625 (15.88) 97-3057-1010-1 MS3420-10 0.562 (14.3) 20/22 1 3/16-18UNEF 97-3057-1012** MS3057-12A M85049/41-12A 0.750 (19.0) 97-3057-1012-1 MS3420-12 0.625 (15.9) 24/28 1 7/16-18UNEF 97-3057-1016** MS3057-16A M85049/41-16A 0.938 (23.80) 97-3057-1016-1 MS3420-16, -12 0.625 (15.9) 32 1 3/4-18UNS 97-3057-1020** MS3057-20A M85049/41-20A 1.250 (31.75) 97-3057-1020-1 MS3420-20, -16 0.750 (19.0) 36 2-18UNS 97-3057-1024** MS3057-24A M85049/41-24A/p> 1.375 (34.92) 97-3057-1024-1 MS3420-24, -20 0.937 (23.8) 40 2 1/4-16UNS - MS3057-28A M85049/41-28A 1.625 (41.28) - - - ** Other platings are available. All dimensions in inches (millimeters in parentheses) MS3057-CAMPHENOL AIB/GT SERIES MS3057-C WATERPROOF CABLE CLAMP

Wire Diameter Optional Bushings Shell Size Part Number Max. Min. Part Number Max. Wire Dia. 10SL MS3057-4C 0.312 (7.93) 0.188 (4.80) MS3420-4A 0.219 (5.56) 14S MS3057-6C 0.438 (11.12) 0.281 (7.10) MS3420-6A 0.312 (7.93) 16/16S MS3057-8C 0.530 (13.48) 0.312 (7.90) MS3420-8A 0.438 (11.10) 18 MS3057-10C 0.625 (15.87) 0.375 (9.50) MS3420-10A 0.438 (11.10) 20/22 MS3057-12C 0.750 (19.00) 0.500 (12.70) MS3420-12A 0.540 (13.74) 24/28 MS3057-16C 0.940 (23.80) 0.625 (15.90) MS3420-16A 0.750 (19.00) 32 MS3057-20C 1.25 (31.75) 0.921 (23.40) MS3420-20A 0.938 (23.80) 36 MS3057-24C 1.38 (35.00) 1.00 (25.40) MS3420-24A 1.12 (28.50) 40 MS3057-28C 1.62 (41.25) 1.25 (31.80) MS3420-28A 1.125 (31.75) All dimensions in inches (millimeters in parentheses) MS3420AMPHENOL AIB/GT SERIES MS3420 TELESCOPING BUSHINGS

Shell Size First Bushing Part Number Inside Diameter 2nd Nested Bushing Inside Diameter Fits in Cable Clamp 10SL MS3420-4 .220 (5.59) NONE - MS3057-4A 14S MS3420-6 .312 (7.92) NONE - MS3057-6A 16S MS3420-8 .437 (11.10) NONE - MS3057-8A 16 MS3420-8 .437 (11.10) NONE - MS3057-8A 18 MS3420-10 .562 (14.30) NONE - MS3057-10A 20 MS3420-12 .625 (15.90) NONE - MS3057-12A 22 MS3420-12 .625 (15.90) NONE - MS3057-12A 24 MS3420-16 .750 (19.05) MS3420-12 .625 (15.90) MS3057-16A 28 MS3420-16 .750 (19.05) MS3420-12 .625 (15.90) MS3057-16A 32 MS3420-20 .937 (23.80) MS3420-16 .750 (19.05) MS3057-20A 36 MS3420-24 1.250 (31.75) MS3420-20 .937 (23.80) MS3057-24A 40 MS3420-28 1.375 (34.92) MS3420-24 1.250 (31.75) SE96-28A4 All dimensions in inches (millimeters in parentheses) MS3420-AAMPHENOL AIB/GT SERIES MS3420-A REDUCTION BUSHINGS

For use with MS3057-C cable clamps (style-C) to reduce the wire sealing diameter. Bushings can be nested, one inside the other, to progressively reduce the inside diameter of the cable clamp. The column labeled “reduction bushings” shows the acceptable nesting options for each clamp. 9767AMPHENOL AIB/GT SERIES 9767 CABLE CLAMPS

Max. Cable Outside Diameter Min. Cable Outside Diameter Shell Size Cable Clamp Inches MM Inches MM Thread Class 2B 10SL 9767-12-4 0.219 5.55 0.020 0.51 5/8-24 UNEF 14S 9767-14-4 0.219 5.55 0.020 0.51 3/4-20 UNEF 14S 9767-14-6 0.344 8.73 0.176 4.47 3/4-20 UNEF 16S/16 9767-16-4 0.219 5.55 0.020 0.51 3/4-20 UNEF 16S/16 9767-16-6 0.344 8.73 0.176 4.47 3/4-20 UNEF 16S/16 9767-16-8 0.438 11.12 0.177 4.50 7/8-20 UNEF 18 9767-18-6 0.344 8.73 0.176 4.47 1-20 UNEF 18 9767-18-8 0.438 11.12 0.177 4.50 1-20 UNEF 18 9767-18-10 0.563 14.29 0.292 7.42 1-20 UNEF 20/22 9767-22-8 0.438 11.12 0.177 4.50 1-3/16-18 UNEF 20/22 9767-22-10 0.563 14.29 0.292 7.42 1-3/16-18 UNEF 20/22 9767-22-12 0.688 17.46 0.370 9.40 1-3/16-18 UNEF 24/28 9767-28-10 0.563 14.29 0.292 7.42 1-7/16-18 UNEF 24/28 9767-28-12 0.688 17.46 0.370 9.40 1-7/16-18 UNEF 24/28 9767-28-16 0.844 21.43 0.536 13.61 1-7/16-18 UNEF 32 9767-32-20 1.031 26.19 0.590 14.99 1-3/4-18 UNS 36 9767-36-16 0.844 21.43 0.536 13.61 2-18 UNS GASKETSAMPHENOL AIB/GT SERIES GASKETS

Synthetic rubber gaskets are used to ensure a moisture-tight seal between a receptacle and the panel. Gaskets are available for front or rear-panel mounting of styles 0, 2, 20, 30 and TB connectors. Gasket thickness is approximately .031 inches (1 mm), for nonconductive and low-temperature types. Conductive shielding gaskets contain an embedded metal screen for EMI/RFI shielding in addition to moisture sealing. Gaskets are available for front or rear-panel mounting of styles 30 and TB connectors. Gasket thickness is .020 inches (.5 mm). Front Mount Rear Mount Shell Size Non-Conductive Conductive Low-Temperature Non-Conductive 10SL 10-040450-010 10-040450-10S 10-036675-010 10-580649-011 14S 10-040450-014 10-040450-14S 10-036675-014 10-580649-014 16S 10-040450-016 10-040450-16S 10-036675-016 10-580649-016 16 10-040450-016 10-040450-16S 10-036675-016 10-580649-016 18 10-040450-018 10-040450-18S 10-036675-018 10-580649-018 20 10-040450-020 10-040450-20S 10-036675-020 10-580649-020 22 10-040450-022 10-040450-22S 10-036675-022 10-580649-022 24 10-040450-024 10-040450-24S 10-036675-024 10-580649-024 28 10-040450-028 10-040450-28S 10-036675-028 10-580649-028 32 10-040450-032 10-040450-32S 10-036675-032 10-580649-032 36 10-040450-036 10-040450-36S 10-036675-036 10-580649-036 40 10-040450-040 10-040450-40S 10-036675-040 10-580649-040 METAL DUST CAPSAMPHENOL AIB/GT SERIES METAL DUST CAPS WITH SASH CHAIN

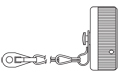

Metal dust caps are used to protect the contacts when the connectors are left unmated. Dust caps come with metal chain lanyards. Dummy Receptacles are for front or rear-panel mounting. AIB/GT Series connectors have bayonet ramps. The center of the connector is closed. Dummy receptacles mount on the same centers and have the same outside dimensions as a STYLE 2 receptacle. A version with a clearance hole through the middle of the connector is also available. Contact us for ordering information. Dust Caps Plug Cap Receptacle Dummy Receptacles Plug Seal Ring

10SL 10-580903-11* 10-580902-11* 10-580595-11* 10-564843-101 14S 10-580903-14* 10-580902-14* 10-580595-14* 10-564843-141 16S 10-580903-16* 10-580902-16* 10-580595-16* 10-564843-161 16 10-580903-17* 10-580902-17* 10-580595-17* 10-564843-161 18 10-580903-18* 10-580902-18* 10-580595-18* 10-564843-181 20 10-580903-20* 10-580902-20* 10-580595-20* 10-564843-201 22 10-580903-22* 10-580902-22* 10-580595-22* 10-564843-221 24 10-580903-24* 10-580902-24* 10-580595-24* 10-564843-241 28 10-580903-28* 10-580902-28* 10-580595-28* 10-564843-281 32 10-580903-32* 10-580902-32* 10-580595-32* 10-564843-321 36 10-580903-36* 10-580902-36* 10-580595-36* 10-564843-161 40 10-580903-40* 10-580902-40* 10-580595-40* 10-564843-401 *Select code for plating: Z = Black anodize 3 = Olive drab cadmium plate 9 = Olive drab cadmium nickel base G = Electroless nickel U = Green zinc Y = Black alloy |

|

SOLDER CONTACTSAMPHENOL AIB/GT SERIES SOLDER CONTACTS

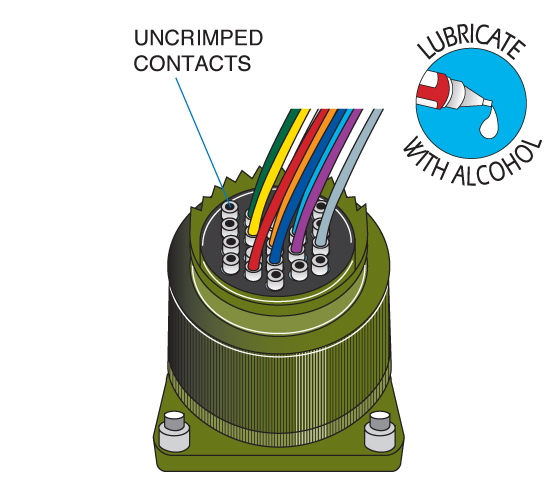

STEP 1: Slide the rear accessories over the wire bundle in the proper sequence for re-assembly: cable clamp and/or endbell first, then ferrule and (if used) coupling nut. STEP 2: Insert individual wires through the proper holes in the grommet. Use isopropyl alcohol as a lubricant. STEP 3: Solder wires to appropriate contacts on the rear of the connector. Information on standard soldering practices is available upon request. Please contact us. STEP 4: Fixture the connector for reassembly using endbell assembly tools. STEP 5: Slide the grommet down the wires (lubricating the grommet with isopropyl alcohol will help). STEP 6: Fill all unused grommet cavities with a wire hole filler to maintain the sealing integrity of the connector. STEP 7: Slide coupling nut, ferrule, and endbell accessories over rear of the connector and tighten. Click here for tooling. CRIMP TOOL OPERATIONAMPHENOL AIB/GT SERIES CRIMP TOOL OPERATION

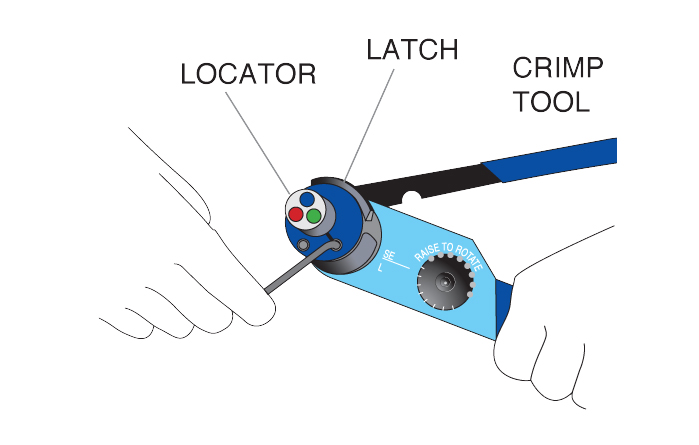

NOTE: Hand-crimp tools can be used with size 16S, 16 & 12 contacts. Size 8, 4 and 0 contacts require the use of air-powered crimp tools. Contact us for assistance in the use of these tools.

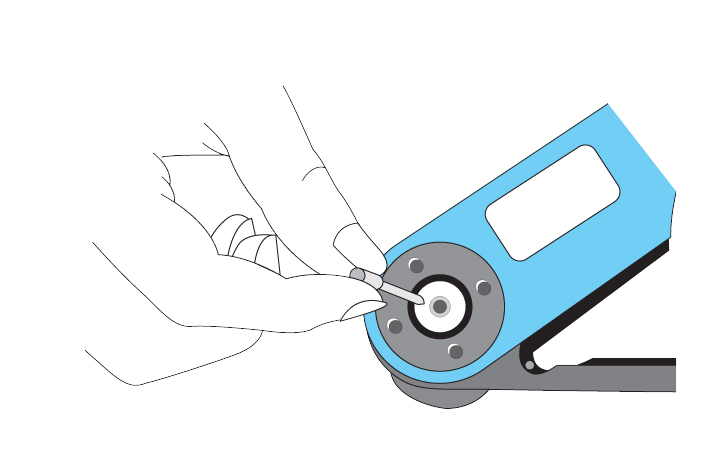

STEP 1: Strip the wires to the appropriate length. See strip lengths on the Contact Selection Guide. STEP 2: Open the crimp tool by squeezing the handles. Push the latch on the turret to pop up the locator. Attach the turret to the crimp tool using the two captive hex bolts in the turret. STEP 3: Select the proper locator position for your contact by rotating the locator until the proper color is aligned with the index mark. Push locator back down until it snaps into position. Contact Size Pin Locator Color Socket Locator Color 16S Red Red 16 Blue Green 16 Green Green

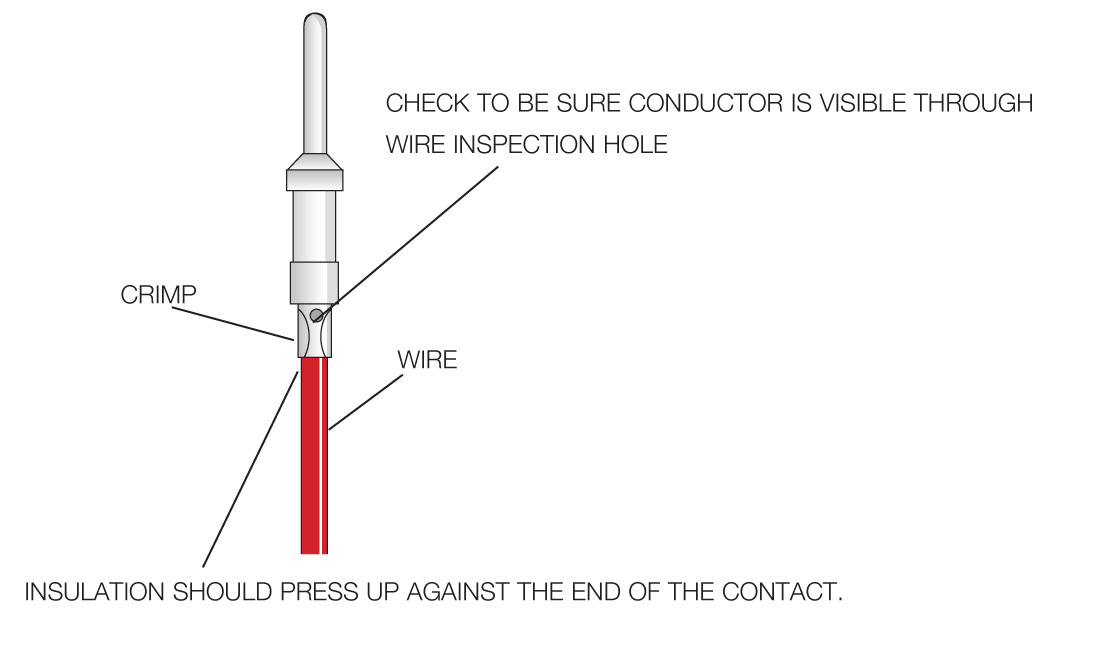

STEP 4: Adjust dial for proper wire gauge. To change the dial setting, remove the lock pin and lift center of dial. Turn to the desired wire gauge. Replace lock pin on dial. STEP 5: Cycle the tool before inserting the contact to be sure the tool is in the open position. Drop the contact, mating end first, into the crimp cavity of the tool. Squeeze the tool handle just enough to grip the contact without actually crimping it. STEP 6: Insert the stripped wire into the contact with a slight twisting motion. Be sure all wire strands are inside the contact. Squeeze the handle to cycle the tool. The handle will not release until the contact is completely crimped.

STEP 7: Remove the crimped contact. Pull on the wire slightly to be sure it is properly crimped. Be sure the contact is not bent or damaged in any way. Visually inspect the crimp.

Crimp Tensile Strength

Size Wire Gauge Lb.

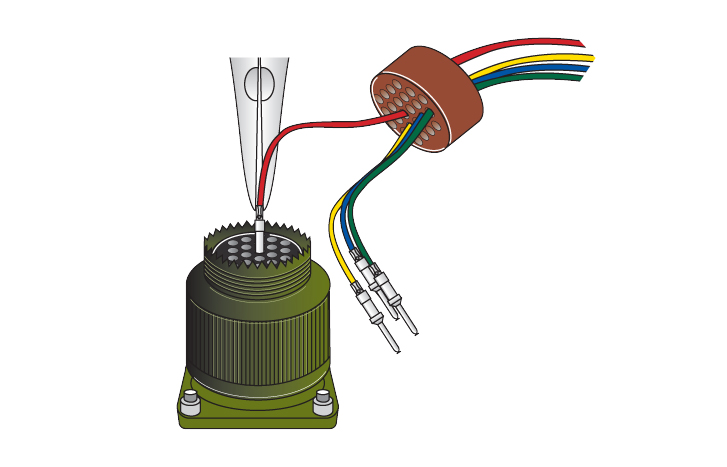

20 20 12 14 70 8 8 185 4 4 450 0 0 800 CONTACT INSERTIONAMPHENOL AIB/GT SERIES CONTACT INSERTION

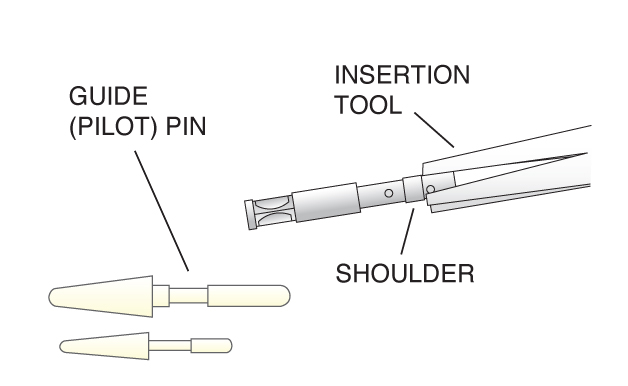

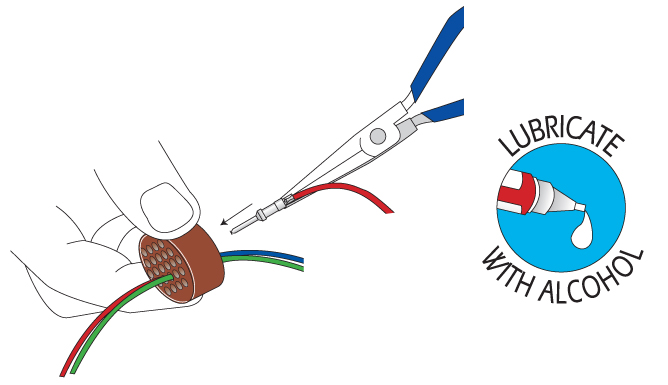

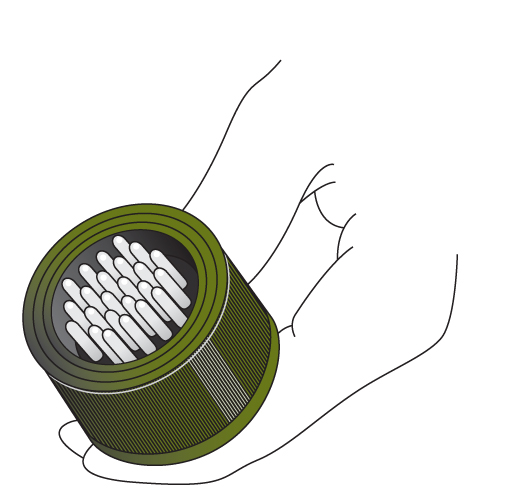

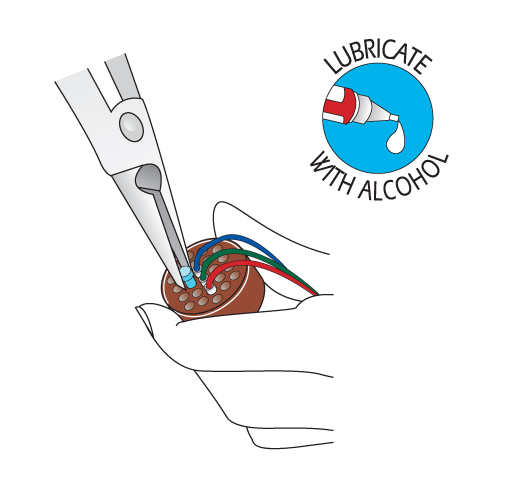

STEP 1: Slide the rear accessories over the wire bundle in the proper sequence for re-assembly: cable clamp and/or endbell first, then ferrule, and coupling nut. STEP 2: Use the proper insertion tool from the Contact Selection Chart. Place the contact in the tool. The tool should press against the shoulder of the contact. Contact sizes 16S, 16, and 12 use a pliers-style tool. Contact sizes 8, 4 and 0 use a tool with a C-shaped shaft. STEP 3: Lubricate the grommet with isopropyl alcohol (do not use any lubricant other than isopropyl alcohol). Insert the contact through the appropriate cavity in the grommet. Sizes 16S, 16 and 12 socket contacts must be installed using guide (pilot) pins. See the Contact Selection Guide for Insertion Guide (Pilot) Pin part numbers.

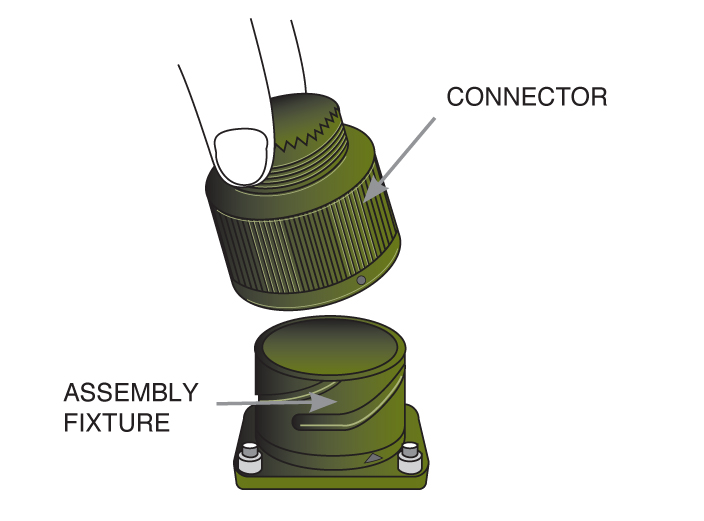

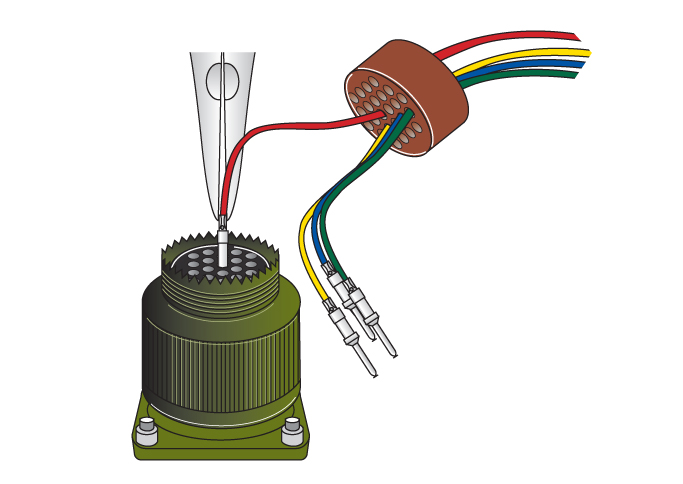

STEP 4: Place the connector into an assembly fixture (fixtures are available for production use, Contact us.) If you are not using a fixture, be sure to allow clearance on the mating face of the connector for the guide pins to come through the connector during insertion. STEP 5: Lubricate the contact cavities of the connector insulator with isopropyl alcohol (do not use any other type of lubricant). STEP 6: Using guide pins where necessary, push straight down with a firm even pressure until the contact snaps into position in the proper cavity. Start at the center of the pattern and work toward the outer edges.

STEP 7: Fill any unused cavities with contacts. STEP 8: Check the mating face of the connector to ensure that all the same size contacts are on the same plane (fully inserted). If not, the contact is not fully inserted. Remove the contact using the proper extraction tool and procedure and reinsert. Do not attempt to reinsert the insertion tool to correct the problem. STEP 9: A wire hole filler must be inserted into the grommet behind the unused contacts to maintain the sealing integrity of the connector. See the Contact Selection Chart for wire hole fillers. STEP 10: Place the connector back in the fixture for re-assembly. Slide the connector accessories back down the cable over the rear of the connector and tighten. Use the appropriate endbell tools. CONTACT EXTRACTIONAMPHENOL AIB/GT SERIES CONTACT EXTRACTION

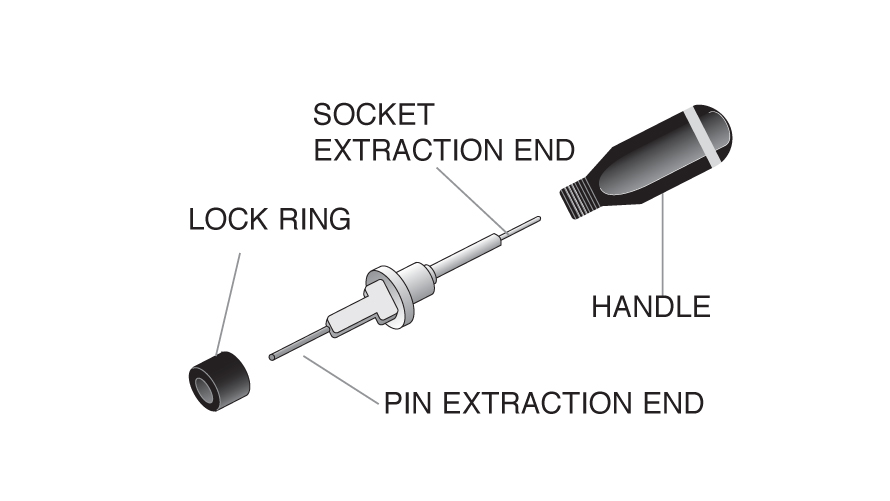

STEP 1: Remove the endbell accessories and slide them back over the wires. Use the appropriate endbell tools. STEP 2: Use the proper extraction tool from the Contact Selection Chart. The extraction tool can be used for both pin and socket contacts by removing the shaft from the handle and reversing it for pin or socket extraction.

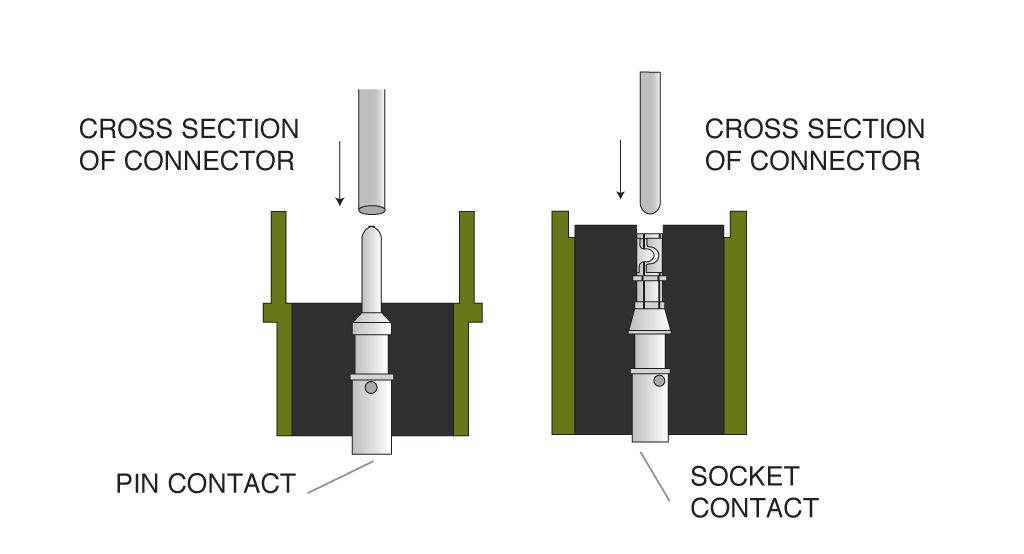

STEP 3: On the mating face of the connector, insert the tool over the pin contact or into the socket contact until the tool bottoms. Apply a slow continuous pressure to push the contact out the rear of the connector. When the shoulder of the tool “thunks” against the insulator, the contact is extracted. STEP 4: Carefully remove the extraction tool from the connector to avoid damage to the insulator. |

Philadelphia

19116

Click here for the contact information of the branch nearest you.