Amphenol JT MIL-DTL-38999 Connector Series II

LIGHT-WEIGHT, LOW-PROFILE, SPACE-SAVING DESIGN

The Amphenol MIL-DTL-38999 series II JT connector offers high-density contact arrangements and shell types in a small size. They were designed for high-performance requirements, including military and commercial aviation applications that require a very low profile. The Amphenol MIL-DTL-38999 series II JT connector is environmentally-sealed and have a wide operating temperature range to meet the demand of harsh environments/conditions.

The Amphenol JT series connector is intermateable with Souriau and all MIL-DTL-38999 series connectors, and were formerly called MIL-C-38999. A broad range of military and commercial accessories are also available. See our full list of Amphenol JT connector MIL-DTL-38999 series II features in the specifications below.

Get shopping! Mil spec part number prefixes include MS27472, MS27473, MS27474, MS27484, MS27497, MS27499, MS27500, MS27508 and MS27513.

|

FEATURESAMPHENOL JT SERIES FEATURES

MATERIALS & FINISHESAMPHENOL JT SERIES MATERIALS & FINISHES

Shell Aluminum alloy or Stainless Steel

Plating A - Clear chromate over cadmium over electroless nickel per QQ-P-416

B - Olive drab chromate over cadmium over electroless nickel per QQ-P-416 F - Electroless nickel per QQ-N-290 C - Hard, anodic, non-conductive in accordance with MIL-A-862 W52 - Olive drab zinc cobalt Contacts Copper alloy

Plating Gold-plated, 50 microinches per MIL-G-45204 type II, grade C, class 1

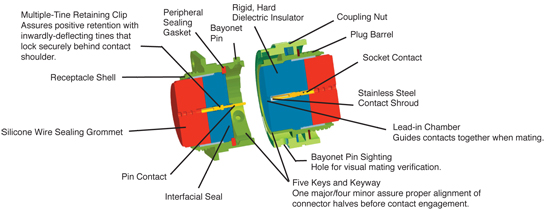

Insulator Hard dielectric wafer that contains metal retention tines for high-reliability retention of crimp contacts

Grommet & Seals Silicone-based elastomer

Grounding Springs Beryllium copper (Grounded plug only)

ELECTRICAL DATAAMPHENOL JT SERIES ELECTRICAL DATA

Test Voltage (unmated condition)Service Rating Test Voltages N M I II Sea Level 1000 1300 1800 2300 100,000 Feet 200 200 200 200 Operating Voltage Service Rating N M I II Operating Voltage 300VAC/450VDC 400VAC/500VDC 600VAC/850VDC 900VAC/1250VDC Current Rating by Contact Size & Wire Accommodation (Test Amps) Wire Size 22D 22M* 22* 20 16 12 28 1.5 1.5 - - - - 26 2.0 2.0 2.0 - - - 24 3.0 3.0 3.0 3.0 - - 22 5.0 - 5.0 5.0 - - 20 - - - 7.5 7.5 - 18 - - - - 10.0 - 16 - - - - 13 - 14 - - - - - 17.0 12 - - - - - 23.0 Contact Resistance of Mated Contacts End-to-End Contact Size Maximum Millivolt Drop 22D 73 22M* 45 22* 73 20 55 16 49 12 42 Insulation Resistance 5,000 megohms minimum

* Inactive for new designs MECHANICALAMPHENOL JT SERIES MECHANICAL

Operating Temperature A - Plating -65°C to 150°C (-85°F to 302°F)

B - Plating -65°C to 175°C (-85°F to 347°F) F - Plating -65°C to 200°C (-85°F to 392°F) C - Anodic (non-conductive) -65°C to 200°C (-85°F to 392°F) W52 - Plating -65°C to 150°C (-85°F to 302°F) Sealing Against sand, dust, per MIL-STD-202 & ice resistance

Wire Sealing Range Contact Sizes Minimum Inches Maximum Inches Minimum MM Maximum MM 22D 0.030 0.054 0.76 1.37 22M* 0.030 0.050 0.76 1.27 22* 0.034 0.060 0.60 1.52 20 0.040 0.083 1.02 2.11 16 0.065 0.109 1.65 2.77 12 0.097 0.142 2.46 3.61 Insulation Strip Length Contact Size Strip Length 22*, 22D or 22M* .125 (3.18) 20 .188 (4.77) 16 .188 (4.77) 12 .188 (4.77) All dimensions in inches (millimeters in parenthesis) Mating Life 500 cycles minimum: 250 for plug with grounding fingers (JTG06)

Salt Spray Finish A: 48-hour per MIL-STD-1344A method 1001 condition B

Finish B: 500-hour per MIL-STD-1344A method 1001 condition C Finish F: 48-hour per MIL-STD-1344A method 1001 condition B Finish C: 500-hour per MIL-STD-1344A method 1001 condition C Finish W52: 48-hour Heat Finish A: 150°C (302°F)

Finish B: 175°C (347°F) Finish F: 200°C (392°F) 1000 hours to MIL-STD-1344 method 1005 Finish C: 200°C (392°F) Finish W52: 175°C (347°F) Chemical Resistance Lubricating oils, hydraulic fluids, coolants, deicing fluids per MIL-STD-1344A Method 1016 condition A-1

Sine Vibration Not applicable

Random Vibration 43.7 grms at ambient temperatures

Shock 300g±15% for 3±1 milliseconds per MIL-DTL-38999L 4.7.23

EMI-Shielding Effectiveness 100 MHz to 10 GHz - minimum attenuation of 45 dB

Contact Type Crimp, fiber optic, co-ax, twinax, thermocouple or printed circuit

Number of Circuits 2 to 128

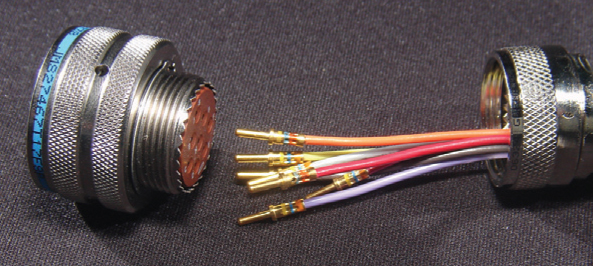

Contact Insertion Rear insertion/rear extraction with simple plastic or high-quality metal hand-tools.

Contact Retention Per MIL-C-38999L tested to MIL-STD-1344A method 2007

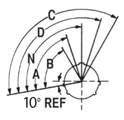

Contact Axial Load Newtons ±10% Axial Load Pounds ±10% 22*, 22D, 22M* 44 10 20 67 15 16 111 25 12 111 25 * Inactive for new designs Polarization Three-point bayonet coupling, five keyways with optional master keyway rotations, note insert and four fixed minor keyways.

Approvals MIL-DTL-38999L

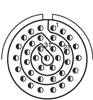

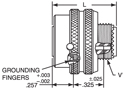

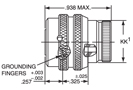

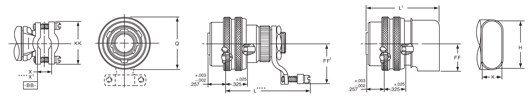

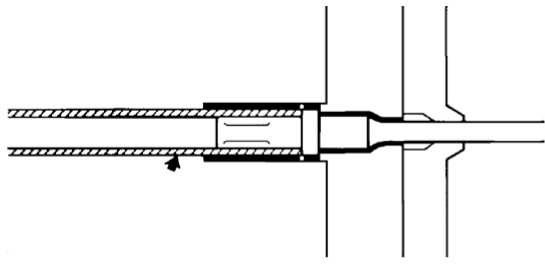

AMPHENOL JT SERIES CROSS-SECTION

AMPHENOL JT SERIES EXCERPT FROM MIL-DTL-38999K

3.43.2 JAN brand. The United States Government has adopted, and is exercising legitimate control over the certification marks “JAN” and “J”, respectively, to indicate that items so marked or identified are manufactured to, and meet all the requirements of military specification. Accordingly, items acquired to, and meeting all of the criteria specified herein and in applicable specifications shall bear the certification mark “JAN” except that items too small to bear the certification mark “JAN” shall bear the letter “J”. The “JAN” or “J” shall be placed immediately before the PIN except that if such location would place a hardship on the manufacturer in connection with such marking, the “JAN” or “J” may be located on the first line above or below the PIN. Items furnished under contracts or orders which either permit or require deviation from the conditions or requirements specified herein or in applicable specifications shall not bear “JAN” or “J”. In the event an item fails to meet the requirements of this specification and the applicable specification sheets or associated detail specifications, the manufacturer shall remove the “JAN” or the “J” from the sample tested and also from all items represented by the sample. The “JAN” or “J” certification mark shall not be used on products acquired to contractor drawings or specification. The United States Government has obtained Certificate of Registration No. 504,860 for the certification mark “JAN”. Note: The “JAN” or “J” is not part of the PIN but indicates a certification. PIN = Part Identification Number |

|

AMPHENOL JT SERIES APPLICATIONS

|

|

STEP 1: SHELLAMPHENOL JT SERIES MILITARY PART NUMBER EXAMPLE

1 2 3A 4 3B 5 6 7 MS27474 T 24 F 35 P A -LC SHELL STYLE CLASS SIZE PLATING LAYOUT CONTACT POLARI- MODIFIER AMPHENOL JT SERIES COMMERCIAL PART NUMBER EXAMPLE

1 2 3 4* 5 6 7 JT07 RE- 24-35 P A -014 -LC SHELL STYLE CLASS LAYOUT CONTACT POLARIZATION (Omit for Normal) PLATING* MODIFIER STEP 1: SELECT SHELL STYLE, PLUG OR RECEPTACLE

MS27472 (JT00R) MS27497 (JTPQ00R) JT01R MS27473 (JT06R) MS27484 (JTG06R)

MS27499E

MS27474 MS27513E MS27508E MS27500 STEP 2: CLASSSTEP 2: SELECT CLASS

E° = Grommet & Compression Nut (not applicable to box mount receptacles)

+ Most Popular STEP 3: LAYOUTSTEP 3: SELECT LAYOUT (LISTED BY SIZE)

Contacts Layout Number Service Rating Total Number 22D 22M 22 20 16 12 8-35 M 6 6 8-44 M 4 4 8-98 I 3 3 8-6 M 6 6 10-4PP● I 4 4 10-5 I 5 5 10-13 M 13 13 10-35 M 13 13 10-98 I 6 6 10-99 I 7 7 12-3 II 3 3 12-4 I 4 4 12-8 I 8 8 12-22 M 22 22 12-35 M 22 22 12-98 I 10 10 14-4● I 4 4 14-5 II 5 5 14-15 I 15 14 1 14-18 I 18 18 14-19● I 19 19 14-35 M 37 37 14-37 M 37 37 14-68● I 8 8 14-97 I 12 8 4 16-6 I 6 6 16-8 II 8 8 16-13● I 13 13 16-26 I 26 26 16-35 M 55 55 16-42 M 42 42 16-55 M 42 42 16-99 I 23 21 2 18-11 II 11 11 18-28 I 28 26 2 18-30 I 30 29 1 18-32 I 32 32 18-35 M 66 66 18-53 M 53 53 18-66 M 66 66 18-68● I 18 18 18-96 I 9 9 20-1 M 79 79 20-2 M 65 65 20-11P● I 11 11 20-16 II 16 16 20-35 M 79 79 20-39 I 39 37 2 20-41 I 41 41 22-1 I 100 100 22-2 M 85 85 22-14● I 14 14 22-21 II 21 21 22-32 I 32 32 22-35 M 100 100 22-53P● I 53 53 22-55 I 55 55 24-1 M 128 128 24-2 M 100 100 24-4 I 56 48 8 24-19● I 19 19 24-24 I 24 12 12 24-29 I 29 29 24-35 M 128 128 24-37 I 37 37 24-43P● I 43 23 20 24-61 I 61 61 ● = NOT QPL'D P = Pin Insert Only Contact us for more information. Read Less LAYOUTS BY NUMBER OF CONTACTS

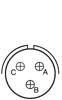

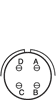

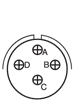

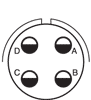

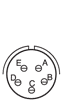

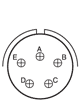

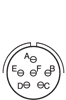

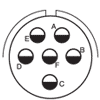

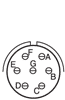

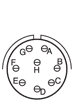

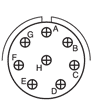

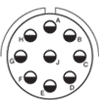

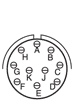

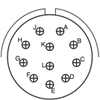

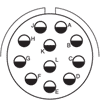

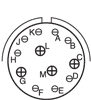

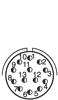

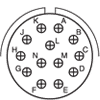

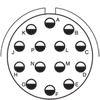

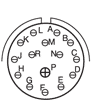

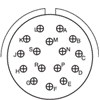

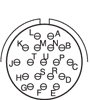

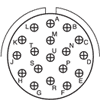

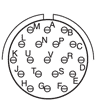

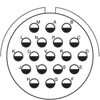

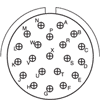

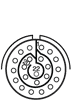

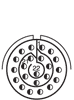

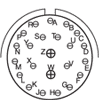

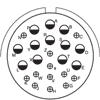

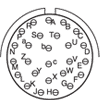

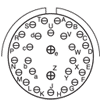

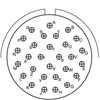

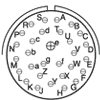

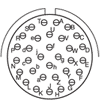

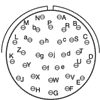

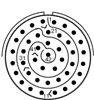

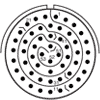

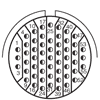

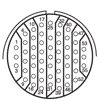

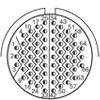

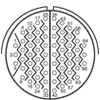

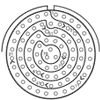

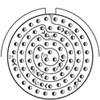

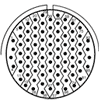

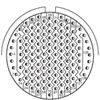

View of Mating-Face of Pin Insert

Contacts 3 4 5 6

Layout 8-98 12-3 8-44 10-4P● 12-4 14-4● 10-5 14-5 8-6 8-35 # of Contacts 3-#20 3-#16 4-#22 4-#20 4-#16 4-#12 5-#20 5-#16 6-#22M 6-#22D Service Rating I II M I I I I II M M Contacts 6 7 8 9

Layout 10-98 16-6 10-99 12-8 14-68● 16-8 18-96 # of Contacts 6-#20 6-#12 7-#20 8-#20 8-#16 8-#16 9-#12 Service Rating I I I I I II I Contacts 10 11 12 13

Layout 12-98 18-11 20-11P● 14-97P• 10-13 10-35 16-13● # of Contacts 10-#20 11-#16 11-#12 8-#20, 4-#16 13-#22M 13-#22D 13-#16 Service Rating I II I I M M M Contacts 14 15 16 18

Layout 22-14● 14-15 20-16 14-18 18-68● # of Contacts 14-#12 14-#20, 1-#16 16-#16 18-#20 18-#16 Service Rating I I II I I Contacts 19 21 22

Layout 14-19● 24-19● 22-21 12-22 12-35 # of Contacts 19-#20 19-#12 21-#16 22-#22M 22-#22D Service Rating I I II M M Contacts 23 24 26 28

Layout 16-99 24-24 16-26 18-28 # of Contacts 21-#22, 2-#16 12-#16, 12#12 26-#20 26-#20, 2-#16 Service Rating I I I I Contacts 29 30 32

Layout 24-29 18-30 18-32 22-32 # of Contacts 29-#16 29-#20, 1-#16 32-#20 32-#20 Service Rating I I I I Contacts 37 39 41

Layout 14-35 14-37 24-37 20-39 20-41 # of Contacts 37-#22D 37-#22M 37-#16 37-#20, 2-#16 41-#20 Service Rating M M I I I Contacts 42 43 53 55

Layout 16-42 24-43P● 18-53 22-53P● 16-35 16-55 # of Contacts 42-#22 23-#20, 20-#16 53-#22 53-#20 55-#22D 55-#22M Service Rating M I M I M M Contacts 55 56 61 65

Layout 22-55 24-4 24-61 20-2 # of Contacts 55-#20 48-#20, 8-#16 61-#20 65-#22 Service Rating I I I M Contacts 66 79 85

Layout 18-35 18-66 20-1 20-35 22-2 # of Contacts 66-#22D 66-#22M 79-#22M 79-#22D 85-#22 Service Rating M M M M M/p> Contacts 100 128

Layout 22-1 22-35 24-2 24-1 24-35 # of Contacts 100-#22M 100-#22D 100-#22 128-#22M 128-#22D Service Rating M M M M M ● = NOT QPL'D P = Pin Insert Only Contact us for more information. Read Less STEP 4: PLATINGSTEP 4: SELECT PLATING

Finish Military Commercial Commerical + SR Cadmium-plated nickel base A - A Olive drab cadmium- plated nickel base B 014 386 Electroless nickel F 023 424 Electroless nickel space-compatible - 453 467 Anodic coating (Alumilite) C 005 300 Chromate-tested (Iridite 14-2) - 011 344 Passivated steel (Hermetic only) E - - Stainless steel - 155 - Olive drab zinc cobalt - W52 - SR = Strain Relief STEP 5: CONTACTSTEP 5: SELECT CONTACT

Note: See Step 7 if not ordering contacts with part. P = Pin A = Less Pin Contacts STEP 6: POLARIZATIONSTEP 6: SELECT POLARIZATION

Shell Size Normal A B C D 8 100 82 - - 118 10 100 86 72 128 114 12 100 80 68 132 120 14 100 79 66 134 121 16 100 82 70 130 118 18 100 82 70 130 118 20 100 82 70 130 118 22 100 85 74 126 115 24 100 85 74 126 115 STEP 7: MODIFIERSTEP 7: SELECT MODIFIER

Note: LC is not marked on part Omit for standard contacts LC = Less contacts, wire hole fillers and plastic insertion/ extraction tool. (Purchase Order must state “Less Contacts”)

|

|

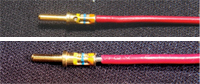

CONTACTSAMPHENOL JT SERIES CONTACTS - PIN

Contact Size Wire Size AWG Pin Contact Color Bands Color Bands Color Bands Wire Strip Lengths Wire Range Wire Range Wire Hole Filler Color 22D 28,26,24 M39029/ Orange Blue Black .125 (3.18) .030 (0.76) .054 (1.37) MS27488-22-2 Black *22M 20,22 & 24 M39029/ Orange Blue Brown .125 (3.18) .030 (0.76) .050 (1.27) MS27488-22-2 Black *22 20,22 & 24 M39029/ Orange Blue Red .125 (3.18) .034 (0.86) .060 (1.52) MS27488-22-2 Black 20 20,22 & 24 M39029/ Orange Blue Orange .188 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16,18 & 20 M39029/ Orange Blue Yellow .188 (4.77) .065 (1.65) .109 (2.77) MS27488-16-2 Blue 12 12 & 14 M39029/ Orange Blue Green .188 (4.77) .097 (2.46) .142 (3.61) MS27488-12-2 Yellow * Inactive for new design AMPHENOL JT SERIES CONTACTS - SOCKETS

Contact Size Wire Size AWG Socket Contact Color Bands Color Bands Color Bands Wire Strip Lengths Wire Range Wire Range Wire Hole Filler Color 22D 28,26,24 M39029/ Orange Green Yellow .125 (3.18) .030 (0.76) .054 (1.37) MS27488-22-2 Black *22M 20,22 & 24 M39029/ Orange Green Green .125 (3.18) .030 (0.76) .050 (1.27) MS27488-22-2 Black *22 20,22 & 24 M39029/ Orange Green Blue .125 (3.18) .034 (0.86) .060 (1.52) MS27488-22-2 Black 20 20,22 & 24 M39029/ Orange Green Violet .188 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16,18 & 20 M39029/ Orange Green Gray .188 (4.77) .065 (1.65) .109 (2.77) MS27488-16-2 Blue 12 12 & 14 M39029/ Orange Green White .188 (4.77) .097 (2.46) .142 (3.61) MS27488-12-2 Yellow Contact Color Codes 0 Black 1 Brown 2 Red 3 Orange 4 Yellow 5 Green 6 Blue 7 Violet 8 Gray 9 White All dimensions in inches (millimeters in parentheses) CONTACT TOOLSAMPHENOL JT SERIES CONTACT TOOLS - PINS

Contact Size Hand-Crimp Tool Power- Crimp Tool Turret Heads Use Locator Color Plastic Insertion/ Extraction Tool Insertion Tip Color Extraction Tip Color Metal Insertion Tool Color Band Metal Extraction Tool Color Band 22D M22520/ WA22 M22520/ - M81969/ Green White MS27495 Black MS27495 Black White *22M M22520/ WA22 M22520/ - M81969 Green White MS27495 Black MS27495 black White *22 M22520/ WA22ƗƗ M22520/ - M81969/ Green White MS27495 Black MS27495 Brown White 20 M22520/ WA27FƗƗ

M22520/ Red M81969/ Red Orange MS27495 Red MS27495 Red White 16 M22520/ WA27FƗƗ

M22520/ Blue M81969/ Blue White MS27495 Blue MS27495 Blue White 12 M22520/ WA2

7FƗƗ M22520/ Yellow M81969/ Yellow White MS27495 Yellow MS27495 Yellow White AMPHENOL JT SERIES CONTACT TOOLS - SOCKETS

Contact Size Hand-Crimp Tool Power- Crimp Tool Turret Heads Use Locator Color Plastic Insertion/ Extraction Tool Insertion Tip Color Extraction Tip Color Metal Insertion Tool Color Band Metal Extraction Tool Color Band 22D M22520/ WA22 M22520/ - M81969/ Green White MS27495 Black MS27495 Black White *22M M22520/ WA22 M22520/ - M81969 Green White MS27495 Black MS27495 black White *22 M22520/ WA22ƗƗ M22520/ - M81969/ Green White MS27495 Black MS27495 Brown White 20 M22520/ WA27FƗƗ

M22520/ Red M81969/ Red Orange MS27495 Red MS27495 Red White 16 M22520/ WA27FƗƗ

M22520/ Blue M81969/ Blue White MS27495 Blue MS27495 Blue White 12 M22520/ WA2

7FƗƗ M22520/ Yellow M81969/ Yellow White MS27495 Yellow MS27495 Yellow White Contact Color Codes 0 Black 1 Brown 2 Red 3 Orange 4 Yellow 5 Green 6 Blue 7 Violet 8 Gray 9 White ƗƗ Contact us for more tool accessories. * Inactive for new design CO-AX CONTACTSAMPHENOL JT SERIES CO-AX CONTACTS

Co-ax Pin Co-ax Socket Crimping Tools

Co-ax Contact Size Cable Type Contact Part Number Contact Part Number Crimping Tools Crimping Tools

RG-178B/U, RG-174A/U, 21-033122-564

21-033123-564

RG-174A/U, RG-180B/U,

21-033122-541

21-033123-541

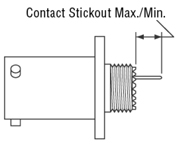

Wire Hole Filler Wire Strip Length Wire Sealing Range Co-ax Contact Size Installation Tools Installation Wire Strip Lengths Wire Sealing Range Wire Sealing Range 16 M81969/8-07 or M81969/8-08 or Contact us for details .065 (1.65) .109 (2.77) 12 M81969/8-09 or M81969/8-10 or Contact us for details .097 (2.46) .142 (3.61) All dimensions in inches (millimeters in parentheses) PCB CONTACTSAMPHENOL JT SERIES PRINTED CIRCUIT BOARD CONTACTS - PIN

Contact Stickout Max./Min. PCB Pin Size Tail Dia. +/- .001 MS27472 MS27497 MS27499 MS27508 MS27473 MS27474 10-407552-015 22M 0.019 .379 /.317 .379 /.317 .577 /.520 .577 /.520 .379/.317 .379/.317 10-407552-055 22M 0.019 .268/.206 .268/.206 .466/.409 .466/.409 .268/.206 .268/.206 10-407552-085 22M 0.019 .104/.047 .104/.047 .302/.250 .302/.250 .104/.047 .104/.047 10-407552-115 22M 0.019 .042 / NS .042 / NS .240 / .188 .240 / .188 .042 / NS .042 / NS 10-497640-015 20 0.019 .392 / .335 .392 / .335 .590 / .538 .590 / .538 .392 / .335 .392 / .335 10-497640-025 20 0.019 .257 / .220 .257 / .220 .455 / .403 .455 / .403 .257 / .220 .257 / .220 10-497640-045 20 0.019 NS NS .192 / .140 .192 / .140 NS NS 10-497596-015 20 0.025 .102 / .049 .102 / .049 .300 / .252 .300 / .252 .102 / .049 .102 / .049 10-497596-025 20 0.025 .192 / .139 .192 / .139 .390 / .342 .390 / .342 .192 / .139 .192 / .139 10-497596-035 20 0.025 .273 / .220 .273 / .220 .471 /.423 .471 /.423 .390 / .337 .390 / .337 10-497596-055 20 0.025 .390 / .337 .390 / .337 .588 / .540 .588 / .540 .390 / .337 .390 / .337 10-497695-015 16 0.040 .299 / .242 .299 / .242 .497 / .445 .497 / .445 .229 / .242 .229 / .242 10-497630-035 16 0.062 .104 / .047 .104 / .047 .302 / .250 .302 / .250 .104 / .047 .104 / .047 10-497630-055 16 0.062 .257 / .200 .257 / .200 .455 / .403 .455 / .403 .272 / .215 .272 / .200 10-597502-015 12 0.081 .272 / .215 .272 / .215 .470 / .418 .470 / .418 .272 / .215 .272 / .215 AMPHENOL JT SERIES PRINTED CIRCUIT BOARD CONTACTS - SOCKET

Contact Stickout Max./Min. PCB Socket Size Tail Dia. +/- .001 MS27472 MS27497 MS27499 MS27508 MS27473 MS27474 10-597880-051 22M 0.019 .268 / .194 .268 / .194 .466 / .395 .466 / .395 .268 / .194 .268 / .194 10-597880-171 22M 0.019 .268 / .178 .268 / .178 .466 / .409 .466 / .409 .268 / .178 .268 / .178 10-597880-081 22M 0.019 .104 / .035 .104 / .035 .302 / .236 .302 / .236 .104 / .035 .104 / .035 10-497641-025 20 0.019 .257 / .220 .257 / .220 .455 / .403 .455 / .403 .257 / .220 .257 / .220 10-497631-055 16 0.062 .257 / .220 .257 / .220 .455 / .403 .455 / .403 .257 / .220 .257 / .220 = Standard PC tail used All dimensions in inches |

|

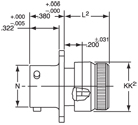

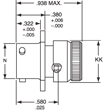

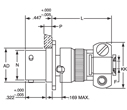

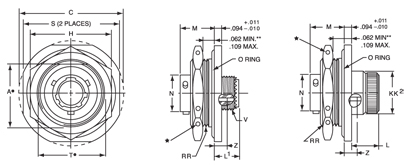

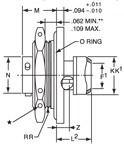

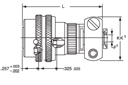

RECEPTACLE STYLESAMPHENOL JT SERIES RECEPTACLE STYLES

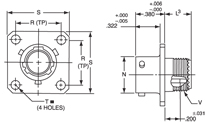

Shell Size F Diameter +.010/ F Diameter +.010 (+.254) L Max L Max L1 Max. L1 Max. L2 Max. MS27472/ L3 Max. MS27497/ N +.001/-.005 (+.025/ P Max. Panel Thickness MS27497 / JTPQ00R 8 0.125 0.444 1.094 1.14 0.609 0.468 0.547 0.5 0.473 0.142 10 0.188 0.558 1.094 1.140 0.609 0.468 0.547 0.500 0.590 0.142 12 0.312 0.683 1.094 1.140 0.609 0.468 0.547 0.500 0.750 0.142 14 0.375 0.808 1.344 1.375 0.609 0.468 0.547 0.500 0.875 0.142 16 0.500 0.909 1.344 1.375 0.609 0.468 0.547 0.500 1.000 0.142 18 0.625 1.034 1.344 1.375 0.609 0.468 0.547 0.500 1.125 0.142 20 0.625 1.159 1.344 1.375 0.609 0.468 0.547 0.5 1.250 0.142 22 0.750 1.284 1.469 1.516 0.609 0.468 0.547 0.500 1.347 0.142 24 0.800 1.409 1.469 1.500 0.688 0.540 0.547 0.500 1.500 0.142

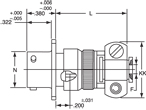

Shell Size C Max. F Diameter +.010 (-.254) F1 Diameter +.010/ L Max. L1 Max. N Diameter +.001/ S +.017/ KK Diameter Max. KK1 Diameter Max. KK2 Max. V Thread Class 2A (Plated) 8 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 0.812 .4375-28 UNEF 10 1.089 0.558 0.188 1.031 0.562 0.590 0.938 0.703 0.750 0.875 .5625-24 UNEF 12 1.183 0.683 0.312 1.031 1.562 0.750 1.031 0.828 0.875 1.000 .6875-20 UNEF 14 1.277 0.808 0.375 1.031 1.812 0.875 1.125 0.953 1.000 1.125 .8125-20 UNEF 16 1.371 0.909 0.500 1.031 1.812 1.000 1.219 1.078 1.125 1.188 .9375-20 UNEF 18 1.465 1.034 0.625 1.031 1.812 1.125 1.312 1.203 1.250 1.438 1.0625-18 UNEF 20 1.589 1.159 0.625 1.031 1.812 1.250 1.438 1.328 1.375 1.438 1.1875-18 UNEF 22 1.715 1.284 0.750 1.031 1.938 1.375 1.562 1.453 1.500 1.625 1.3125-18 UNEF 24 1.838 1.409 0.800 1.109 1.938 1.500 1.688 1.578 1.625 1.719 1.4375-18 UNEF

SS Diameter +.000/-.016 (+.000/ Shell Size R (TP) S ±.016 (±.406) T Diameter ±.005 (±.127) V Thread Class 2A (Plated) MS27497/ JTPQ00R MS27472/ JTPQ00R MS27472/ JTPQ00R KK1 Diameter Max. KK2 Diameter Max. MS27497/ JTPQ00R 8 0.594 0.812 0.125 .4375-28 UNEF 0.516 0.812 0.781 0.625 0.578 0.563 10 0.719 0.938 0.120 .5625-24 UNEF 0.663 0.875 0.844 0.750 0.703 0.680 12 0.812 1.031 0.120 .6875-24 UNEF 0.802 1.000 0.969 0.875 0.828 0.85 14 0.906 1.125 0.120 .8125-20 UNEF 0.927 1.125 1.094 1.000 0.953 0.98 16 0.969 1.219 0.120 .9375-20 UNEF 1.052 1.188 1.154 1.125 1.078 1.10 18 1.062 1.312 0.120 1.0625-18 UNEF 1.177 1.438 1.406 1.250 1.203 1.23 20 1.156 1.438 0.120 1.1875-18 UNEF 1.302 1.438 1.406 1.375 1.328 1.35 22 1.250 1.562 0.120 1.3125-18 UNEF 1.427 1.625 1.594 1.500 1.453 1.48 24 1.375 1.688 0.147 1.4375-18 UNEF 1.552 1.719 1.688 1.625 1.578 1.61

AD Diameter ±.005 (±.127)

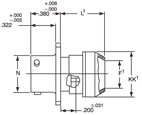

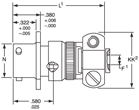

Shell Size MS27499/ JT02RE MS27513/ JT02RE MS27508/ JTP02RE N +.001/-.005 (+.025/ MS27508/ JTP02RE R (TP) S ±.016 (±.406) T Diameter ±.005 (±.127) MS27508/ JTP02R MS27499/ JT02RE MS27513/ JT02RE MS27508/ JTP02RE 8 0.286 0.225 0.473 0.147 0.594 0.812 0.120 0.516 0.438 0.531 10 0.286 0.225 0.590 0.152 0.719 0.938 0.120 0.633 0.563 0.656 12 0.286 0.225 0.750 0.152 0.812 1.031 0.120 0.802 0.688 0.828 14 0.286 0.225 0.875 0.152 0.906 1.125 0.120 0.927 0.813 0.953 16 0.286 0.225 1.000 0.152 0.969 1.219 0.120 1.052 0.938 1.078 18 0.286 0.225 1.125 0.152 1.062 1.312 0.120 1.177 1.047 1.203 20 0.286 0.225 1.250 0.179 1.156 1.438 0.120 1.302 1.172 1.328 22 0.286 0.225 1.375 0.179 1.250 1.562 0.120 1.427 1.297 1.453 24 0.286 0.225 1.500 0.169 1.375 1.688 0.147 1.552 1.422 1.578

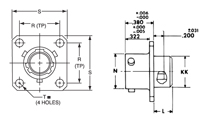

JT07RT (MS27474T) JT07RE (MS27474E) Shell Size A• +.000/-.010 (+.000/-.254) C Max. F Diameter +.010/-.025 (+.254/-.635) F1 Diameter H Hex. +.017/-.016 (+.432/-.406) L Max. L1 Max. L2 Max. L3 Max. 8 0.830 1.390 0.125 0.444 1.062 0.484 0.453 0.563 1.047 10 0.955 1.515 0.188 0.558 1.188 0.484 0.453 0.563 1.047 12 1.084 1.640 0.312 0.683 1.312 0.484 0.453 0.563 1.047 14 1.208 1.765 0.375 0.808 1.438 0.484 0.453 0.563 1.297 16 1.333 1.953 0.500 0.909 1.562 0.484 0.453 0.563 1.297 18 1.459 2.031 0.625 1.034 1.688 0.484 0.453 0.563 1.297 20 0.286 0.225 0.473 0.147 0.594 0.812 0.120 0.516 0.531 22 1.701 2.280 0.750 1.284 2.000 0.453 0.422 0.531 1.391 24 1.826 2.405 0.800 1.409 2.125 0.375 0.422 0.609 1.391

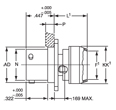

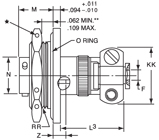

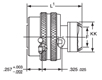

Shell Size M ±.005 (±.127) N ±.001/-.005 (+.025/ S ±.016 (±.406) T• +.010/-.000 (+.254/ V Thread Class 2A (Plated) Z ±.031 (±.787) KK Max. KK1 Dia. Max. KK2 Dia. Max. RR Thread Class 2A (Plated) 8 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 10 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 12 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 14 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 16 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 18 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 20 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 22 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF 24 0.965 0.444 0.125 1.031 1.562 0.473 0.812 0.578 0.625 .4375-28 UNEF • “D” shaped mounting hole dimensions All dimensions in inches (millimeters in parentheses) PLUG STYLESAMPHENOL JT SERIES PLUG STYLES

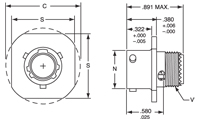

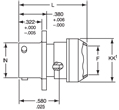

F1 Dia. +.010/

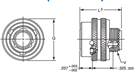

Shell Size F Dia. MS2747 MS2747 MS2748 L1 Max. MS2747 MS2747 Q Dia. Max. Class 2A UNEF Modified Major Dia. KK Dia. Max. MS2747 MS2748 MS27473 8 0.444 0.125 1.562 0.891 1.000 0.938 0.891 0.734 .4375 .421- 0.625 0.812 0.578 0.578 10 0.558 0.188 1.562 0.891 1.000 0.938 0.891 0.844 .5625-24 .542 - .538 0.750 0.875 0.703 0.703 12 0.683 0.312 1.562 0.891 1.000 0.938 0.891 1.016 .6875-24 .667 - .663 0.875 1.000 0.828 0.828 14 0.808 0.375 1.812 0.891 1.000 0.938 0.891 1.141 .8125-20 .791 - .787 1.000 1.125 0.953 0.953 16 0.909 0.500 1.812 0.891 1.000 0.938 0.891 1.265 0.937-20 0.916 -.912 1.125 1.188 1.078 1.078 18 1.034 0.625 1.812 0.891 1.000 0.938 0.891 1.391 1.0625-18 1.034-1.030 1.250 1.438 1.203 1.203 20 1.159 0.625 1.812 0.891 1.000 0.938 0.891 1.500 1.1875-18 1.158-1.154 1.375 1.438 1.328 1.328 22 1.284 0.750 1.938 0.891 1.000 0.938 0.891 1.625 1.3125-18 1.283-1.279 1.500 1.625 1.453 1.453 24 1.409 0.800 1.983 0.891 1.062 0.938 0.891 1.750 1.4375-18 1.408-1.404 1.625 1.719 1.578 1.578

JT08RE (MS27500E) JT08RP Shell Size H K L L1 Q X X1 FF FF1 KK 8 0.547 0.156 1.578 1.125 0.734 0.082 0.234 0.438 0.984 0.755 10 0.709 0.188 1.578 1.156 0.844 0.082 0.234 0.516 1.016 0.755 12 0.829 0.281 1.656 1.250 1.016 0.114 0.328 0.594 1.078 0.817 14 1.000 0.438 1.844 1.406 1.141 0.176 0.457 0.656 1.203 0.943 16 1.021 0.500 2.000 1.469 1.265 0.238 0.634 0.719 1.265 1.067 18 1.145 0.562 2.046 1.531 1.391 0.208 0.614 0.781 1.328 1.149 20 1.270 0.625 2.125 1.594 1.500 0.302 0.608 0.844 1.359 1.399 22 1.395 0.688 2.250 1.656 1.625 0.302 0.823 0.906 1.421 1.399 24 1.520 0.750 2.422 1.797 1.750 0.332 0.853 0.969 1.703 1.587 All dimensions in inches (millimeters in parentheses) |

|

TOOLING ACCESSORIESAMPHENOL JT SERIES CONNECTOR TOOLS

TG70 Strap Wrench

TG69P Non-Marring Adjustable Endbell Pliers for Field Service 600 Series Production System The 600 series is a complete system for the proper assembly and torquing of connector endbells. The system includes a bench-mounted or hand-held torque wrench, plug and receptacle holders, and a range of endbell tightening tools. When used together, these tools provide the user with consistent endbell installations. Each item is shipped with detailed assembly instructions.

Plug and Receptacle Holders

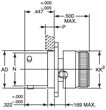

Series II MIL-DTL-38999 MIL-DTL-38999 9 600FF005-8R# 600FF005-8P# 11 600FF005-10R# 600FF005-10P# 13 600FF005-12R# 600FF005-12P# 15 600FF005-14R# 600FF005-14P# 17 600FF005-16R# 600FF005-16P# 19 600FF005-18R# 600FF005-18P# 21 600FF005-20R# 600FF005-20P# 23 600FF005-22R# 600FF005-22P# 25 600FF005-24R# 600FF005-24P# # Add Polarizations: N, A, B, C, D, E AMPHENOL JT SERIES FLANGED PANEL CUTOUTS

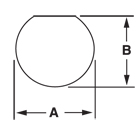

Shell A A H R 8 0.516 (13.11) 0.557 (14.15) 0.125 (3.18) 0.594 (15.09) 10 0.625 (15.88) 0.682 (17.32) 0.125 (3.18) 0.719 (18.26) 12 0.750 (19.05) 0.854 (21.69) 0.125 (3.18) 0.812 (20.62) 14 0.906 (23.01) 0.979 (24.87) 0.125 (3.18) 0.906 (23.01) 16 1.016 (25.81) 1.104 (28.04) 0.125 (3.18) 0.969 (24.61) 18 1.141 (28.98) 1.229 (31.22) 0.125 (3.18) 1.062 (26.97) 20 1.266 (32.16) 1.354 (34.39) 0.125 (3.18) 1.156 (29.36) 22 1.375 (34.93) 1.479 (37.57) 0.125 (3.18) 1.250 (31.75) 24 1.484 (37.69) 1.760 (44.70) 0.152 (3.86) 1.375 (34.93) Click here for Nut Plates and Sealing Screws AMPHENOL JT SERIES JAM NUT PANEL CUTOUTS

Shell A Diameter + .10 (.25) -0 (0) B Flat +.00 (0.0) -.010(-.25) 8 0.885 (22.48) 0.830 (21.08) 10 1.010 (25.64) 0.955 (24.26) 12 1.135 (28.83) 1.085 (27.56) 14 1.260 (32.01) 1.210 (30.73) 16 1.385 (35.18) 1.335 (33.91) 18 1.510 (38.35) 1.460 (37.08) 20 1.635 (41.53) 1.585 (40.26) 22 1.760 (44.70) 1.710 (43.43) 24 1.885 (47.88) 1.835 (46.61) AMPHENOL JT SERIES PANEL THICKNESS

Shell MS27497 MS27508 8 .142 (3.01) .147 (3.73) 10 .142 (3.01) .152 (3.86) 12 .142 (3.01) .152 (3.86) 14 .142 (3.01) .152 (3.86) 16 .142 (3.01) .152 (3.86) 18 .142 (3.01) .152 (3.86) 20 .142 (3.01) .179 (4.55) 22 .142 (3.01) .179 (4.55) 24 .142 (3.01) .169 (4.29) All dimensions in inches (millimeters in parentheses) ACCESSORIESAMPHENOL JT SERIES DUMMY RECEPTACLES, DUST CAPS & PLUG CAPS

Receptacle Dust Caps JT Shell Size Dummy Receptacles For Flanged For Jam Nut Plug Cap 8 M38999/10-8B MS27511**8C MS27511**8N MS27510**8CL 10 M38999/10-10B MS27511**10C MS27511**10N MS27510**10CL 12 M38999/10-12B MS27511**12C MS27511**12N MS27510**12CL 14 M38999/10-14B MS27511**14C MS27511**14N MS27510**14CL 16 M38999/10-16B MS27511**16C MS27511**16N MS27510**16CL 18 M38999/10-18B MS27511**18C MS27511**18N MS27510**18CL 20 M38999/10-20B MS27511**20C MS27511**20N MS27510**20CL 22 M38999/10-22B MS27511**22C MS27511**22N MS27510**22CL 24 M38999/10-24B MS27511**24C MS27511**24N MS27510**24CL ** Select code for plating B = Olive Drab Chromate over Cadmium over Nickel (500-Hour Salt Spray) (Most Popular) F = Electroless Nickel (Fluid Resistant) A = Gold Iridite over Cadmium Nickel C = Hard Anodize

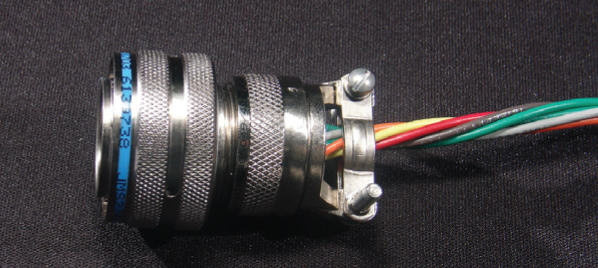

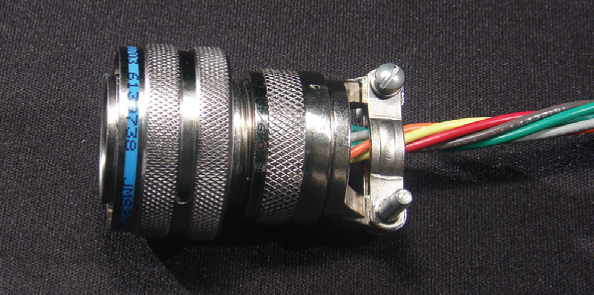

JT Shell Size Endbells Straight Low-Cost Endbells Right Angle Low-Cost Cable Range Min. Cable Range Max. 8 M85049/49-2-8** M85049/47**8 .098 (2.49) .234 (5.94) 10 M85049/49-2-10** M85049/47**10 .153 (3.89) .234 (5.94) 12 M85049/49-2-12** M85049/47**12 .190 (4.83) .328 (8.33) 14 M85049/49-2-14** M85049/47**14 .260 (6.60) .457 (11.61) 16 M85049/49-2-16** M85049/47**16 .283 (7.19) .614 (15.60) 18 M85049/49-2-18** M85049/47**18 .325 (8.25) .634 (16.10) 20 M85049/49-2-20** M85049/47**20 .343 (8.71) .698 (17.73) 22 M85049/49-2-22** M85049/47**22 .381 (9.68) .823 (20.90) 24 M85049/49-2-24** M85049/47**24 .418 (10.62) .853 (21.67) ** Select code for plating W = Olive Drab Chromate over Cadmium over Nickel (500-Hour Salt Spray) (Most Popular) N= Electroless Nickel (Fluid Resistant) A = Hard Anodize

JT Shell Size Endbells Straight Cable Range Right Angle Min. Max. 8 M85049/49-2S8** M85049/47S**8 .098 (2.49) .234 (5.94) 10 M85049/49-2S10** M85049/47S**10 .153 (3.89) .234 (5.94) 12 M85049/49-2S12** M85049/47S**12 .190 (4.83) .328 (8.33) 14 M85049/49-2S14** M85049/47S**14 .260 (6.60) .457 (11.61) 16 M85049/49-2S16** M85049/47S**16 .283 (7.19) .614 (15.60) 18 M85049/49-2S18** M85049/47S**18 .325 (8.25) .634 (16.10) 20 M85049/49-2S20** M85049/47S**20 .343 (8.71) .698 (17.73) 22 M85049/49-2S22** M85049/47S**22 .381 (9.68) .823 (20.90) 24 M85049/49-2S24** M85049/47S**24 .418 (10.62) .853 (21.67) ** Select code for connector plating W = Olive Drab Chromate over Cadmium over Nickel (1000-Hour Salt Spray) N = Electroless Nickel (Fluid Resistant) S = 300-Series Steel, Passivated AMPHENOL JT SERIES STANDARD MIL-SPEC ACCESSORIES

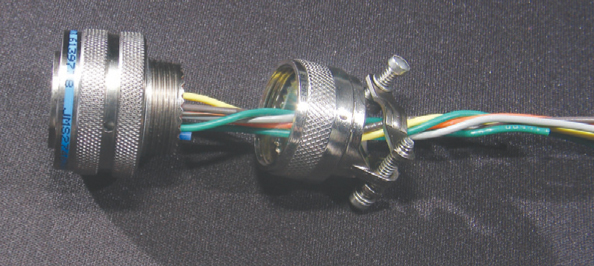

Sealed EMI/RFI Orientation Endbell Type Description M85049/62 Y N S Heat Shrink Boot Adapters Designed for use with straight or right angle shrink boots. A knurled rear section with a boot groove provides excellent surface for the boot to grab the metal endbell. Available with lock wire and drain holes. See Heat Shrink Boots. M85049/33 N Y S Shield Termination Back Shell Non-environmental designed for use with jacketed cable. Allow extra space to break out the wires and still provide stain relief clamping to the outside of the cable jacket. M85049/17 Y Y S Extender Back Shell This EMI/RFI-shielding, environmentally-sealed endbell features a standard-style cable clamp with gland seal at the end of an extender-style backshell. M85049/29 N N S Extender Back Shell This EMI/RFI-shielding, non-environmentally-sealed endbell features a standard-style cable clamp. Banding Y Y

Banding Adapter Banding adapters utilize a band of metal that fastens and grounds cable shields to the outside of endbells. This method of terminating shields has advantages in that they typically use tools to tighten and trim the bands. These tools make the termination tight, repeatable, reworkable (if you make a mistake, just cut the band off and start again) and facilitates service. Banding adapters help lower the total applied cost by having simpler designs that have fewer parts with uncomplicated assembly procedures. Custom SAB Custom Designs If the military-standard endbells don’t fit your needs, contact us and we will customize an endbell solution. Most of these customized endbells are typically assembled in 4-8 weeks or sooner! M85049/27 N N S E-Nut Wire seal compression nut All dimensions in inches (millimeters in parentheses) |

|

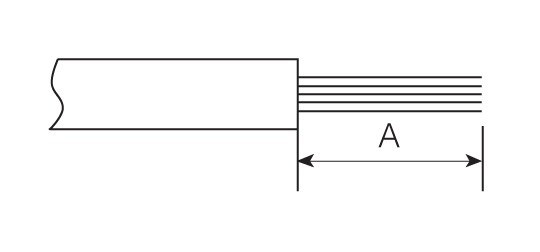

WIRE STRIPPINGAMPHENOL JT SERIES WIRE STRIPPING

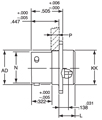

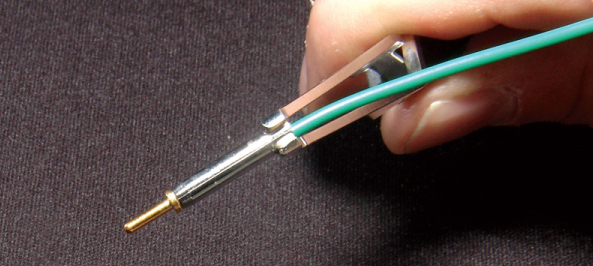

WIRE SIZE A 22, 22M, 22D .125 (3.18) 20 .188 (4.77) 16 .188 (4.77) 12 .188 (4.77) 10 .355 (8.51) All dimensions in inches (millimeters in parentheses) CONTACT CRIMPINGAMPHENOL JT SERIES CONTACT CRIMPING

Correct

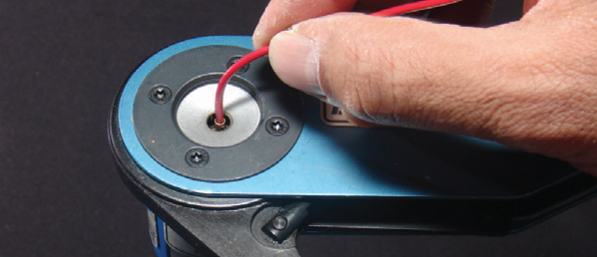

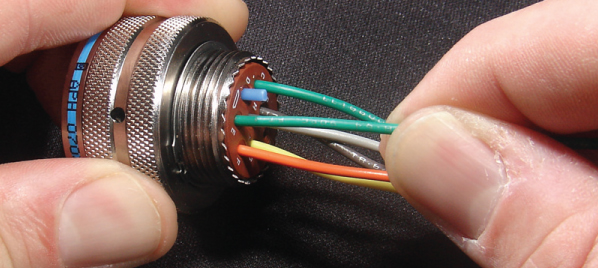

STEP 1: Insert wire into rear of contact. Wire insulation must press against rear of contact. Wire must be visible through inspection hole. STEP 2: M22520 series crimp tool and locator is recommended. Click here for choice of turret head and selection setting according to contact size, part number and wire gauge size. STEP 3: Insert contact and wire into tool jaws. To crimp, squeeze handles together fully until ratchet releases and allows handles to expand; otherwise, contact cannot be extracted from tool jaws. Maintain slight insertion pressure on wire while crimping contact to wire. CONTACT INSERTIONAMPHENOL JT SERIES CONTACT INSERTION

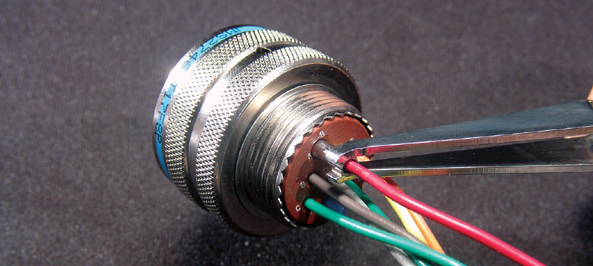

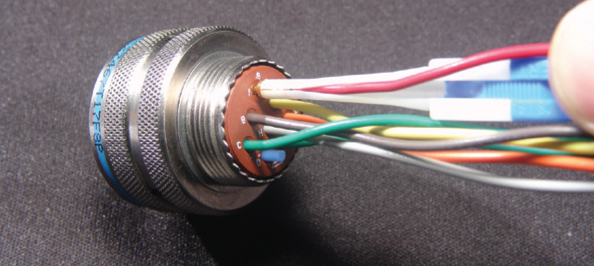

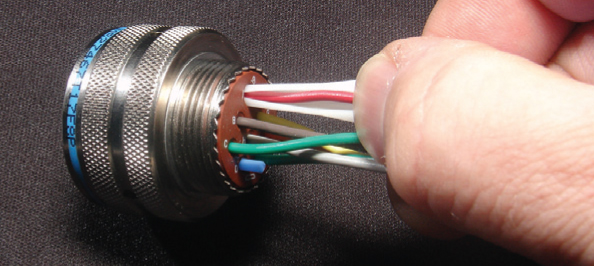

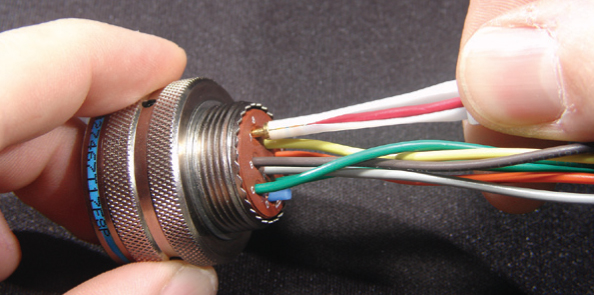

STEP 1: Remove hardware from plug or receptacle and slip over wire bundle in proper order for reassembly. STEP 2: Using proper plastic or metal insertion tool for corresponding contact, position wire in tip of the tool so that the tool tip presses against the contact shoulder. STEP 3: Press tool against contact shoulder and, with firm and even pressure, insert wired contact and tool tip into center contact cavity.

STEP 4: When contact bottoms, a slight “click” can be heard as tines of metal retaining clip snap into place behind contact shoulder. STEP 5: Remove tool and pull back lightly on wire to make sure contact is properly seated. Repeat operation with remainder of contacts to be inserted, beginning with the center cavity and working outward in alternating rows. STEP 6: After all contacts are inserted, fill any empty cavities with wire sealing plugs. Reassemble plug or receptacle hardware. CONTACT EXTRACTIONAMPHENOL JT SERIES CONTACT EXTRACTION

STEP 1: Remove hardware from plug or receptacle and slide hardware back along wire bundle. STEP 2: Using plastic or metal extraction tool with proper color code corresponding to contact size, place wire in tool. STEP 3: Insert tool into contact cavity until tool tip bottoms against the contact shoulder, expanding clip retaining tines.

STEP 4: Hold wire firmly in tool and extract wired contact and tool. Repeat operation for all contacts to be extracted. STEP 5: Fill any empty cavities with wire sealing plugs. Reassemble plug or receptacle hardware. All dimensions in inches (millimeters in parentheses) |

Philadelphia

19116

Click here for the contact information of the branch nearest you.