Amphenol MB Series Connectors (MIL-DTL-26482 Series II)

HIGH-PERFORMANCE MINIATURE CONNECTOR PERFECT FOR AEROSPACE APPLICATIONS

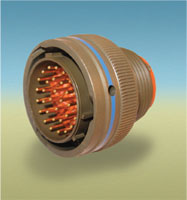

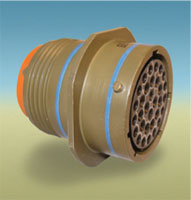

Amphenol’s MB MIL-DTL-26482 series II (Matrix®) miniature cylindrical connectors have a quick-mating, three-point bayonet coupling system. Given their small size and high-quality contact retention and seal, MB series connectors are excellent for high-reliability applications in the harshest conditions, including the aerospace industry. These connectors intermate with all MIL-DTL-26482 series I connectors. Space-rated Class G outgassing is available in 48 hours. For full product details on Amphenol MB series connectors, please see the specifications below.

Get shopping! Mil Spec prefixes include MS3470, MS3471, MS3472, MS3474, MS3476 and MS3475. Amphenol proprietary prefix is MB.

|

FEATURESAMPHENOL MB SERIES FEATURES

MATERIALS & FINISHESAMPHENOL MB SERIES MATERIALS & FINISHES

Shell High-grade aluminum alloy per QQ-A-367, QQ-A-591 or QQ-A-225; stainless

steel 303 grade (AMS 5640)

Jam Nut Aluminum alloy per QQ-A-225

Coupling Nut High-grade aluminum alloy per QQ-A-591; stainless steel

303 grade (AMS 5640)

Shell Plating Cadmium, Anodized, Electroless Nickel, Zinc Alloy, or Passivated

Bayonet Pins Passivated stainless steel per QQ-S-763

Contacts Copper alloy

Contact Plating Gold-plated per MIL-G-45204 50 microinches

Insulator Rigid-plastic dielectric

Grommet & Seals Silicone-based elastomer

ELECTRICAL DATAAMPHENOL MB SERIES ELECTRICAL DATA

Working & Test Voltage Service Rating Working Test At Sea Level 70,000 feet At Sea Level 70,000 feet I 600 300 1,500 375 II 1,000 450 2,300 500 Current Rating

Max. Current Potential drop 24 20 3 20 20 7.5 20 16 7.5 16 16 13 14 12 17 12 12 23 Wire Range Sizes 24 – 12 AWG

Insulation Resistance 5,000 megohms minimum at 77°F (25°C) 500 megohms minimum at 392°F (200°C)

Class L and 347°F (175°C) Class W MECHANICALAMPHENOL MB SERIES MECHANICAL

Operating Temperature Electroless nickel and olive drab chromate over cadmium over nickel

-67°F up to +392°F (-55°C up to +200°C)

Wire Sealing Range Min. Wire Sealing Range Max. 20 .040 (1.02) .083 (2.11) 16 .053 (1.35) .103 (2.62) 12 .097 (2.46) .158 (4.01) Insulation Strip Length

Wire Size Strip Length 20 20-24 .188 (4.76) 16 16-20 .281 (7.14) 12 12-14 .281 (7.14) All dimensions in inches (millimeters in parentheses) Mating Life 500 cycles minimum, 250 cycles minimum for shielded plug

Salt Spray Class L, 48 hours unmated; Class W, 500 hours mated; 452 hours mated per

MIL-STD-1344 Method, 1001 per MIL-DTL-26482 black zinc, 500 hours

Heat All platings and materials, +392°F (+200°C); for 1000 hours to MIL-STD-1344

Method 1005.1

Chemical Resistance Tested unmated according to MIL-DTL-26482 4.6.28 for hydraulic fluid, lubricating

oil, deicing fluids, jet fuels, solvents and coolants

Vibration 10 to 2000Hz (20g’s) 10 microseconds maximum discontinuity.

To MIL-STD-1344 Method 2005 per MIL-DTL-26482

Shock 150g’s 6ms duration, three major axes. 10 microsecond

maximum discontinuity

Contact Type Crimp, co-ax, twinax, thermocouple, printed circuit board, and fiber optic

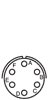

Number of Circuits 3 to 61

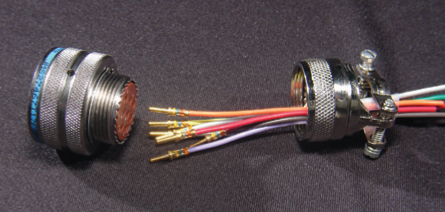

Contact Insertion & Extraction Insertion from rear of connector with simple plastic or high-quality metal hand-tool. Extraction from rear with plastic or high-quality metal hand-tools

Contact Retention Per MIL-STD-1344A Method 2007 per MIL-DTL-26482

Axial Load Pounds Min. 20 20 16 25 12 30 Approvals MIL-DTL-26482

Excerpt from MIL-DTL-26482H

3.7.4 JAN and J marking. The United States Government has adopted and is exercising legitimate control over the certification marks “JAN” and “J”, respectively, to indicate that items so marked or identified are manufactured to, and meet all the requirements of specifications. Accordingly, items acquired to, and meeting all of the criteria specified herein and in applicable specifications shall bear the certification mark “JAN” except that items too small to bear the certification mark “JAN” shall bear the letter “J”. The “JAN” or “J” shall be placed immediately before the PIN except that if such location would place a hardship on the manufacturer in connection with such marking, the “JAN” or “J” may be located on the first line above or below the PIN. Items furnished under contracts or orders which either permit or require deviation from the conditions or requirements specified herein or in applicable specifications shall not bear “JAN” or “J”. In the event an item fails to meet the requirements of this specification and the applicable specification sheets, the manufacturer shall remove completely the military PIN and the “JAN” or the “J” from the sample tested and also from all the items represented by the sample. The “JAN” or “J” certification mark shall not be used on products acquired to contractor drawings or specification. The United States Government has obtained Certificate of Registration Number 504,860 for the certification mark “JAN” and Registration Number 1,586,261 for the certification mark “J”. PIN = Part Identification Number |

|

AMPHENOL MB SERIES APPLICATIONS

|

|

STEP 1: SHELLAMPHENOL MB SERIES MILITARY PART NUMBER EXAMPLE

1 2 3 4 5 6 MS3470° L° 24-61 P W -LC SHELL STYLE FINISH LAYOUT CONTACT ROTATION MODIFIER AMPHENOL MB SERIES COMMERCIAL PART NUMBER EXAMPLE

1 2 3 4 5 6 MB10* B* 24-61 P W -A15 SHELL STYLE FINISH LAYOUT CONTACT ROTATION MODIFIER STEP 1: SELECT SHELL STYLE, PLUG OR RECEPTACLE

MS3476 MS3475 MS3470 MS3471 MS3472 MS3474 + Most Popular STEP 2: FINISHSTEP 2: SELECT FINISH

L° (R)* = Electroless Nickel (RoHS) W*° = Olive Drab Chromate over Cadmium over Nickel 500 Hour Salt Spray G* = Stainless Steel 303 Grade (AMS 5640) A*° = Black Anodized B* = Conductive Black Alloy (RoHS with A15 mod code) * Commercial ° Military ** Green Zinc & Durmalon platings are available, please contact us for details. STEP 3: LAYOUTSTEP 3: SELECT LAYOUT

Rotations

Service Rating Total Number of Contacts

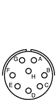

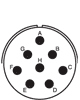

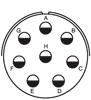

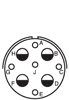

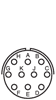

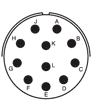

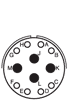

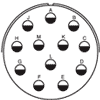

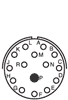

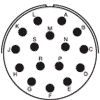

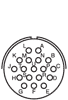

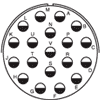

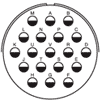

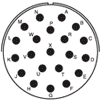

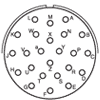

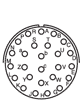

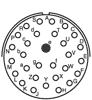

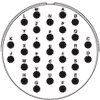

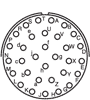

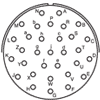

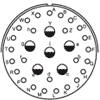

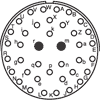

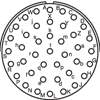

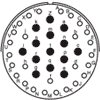

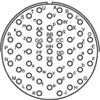

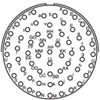

8-33 I 3 3 90 - - - 8-98 I 3 3 - - - - 10-6 I 6 6 90 - - - 12-3 II 3 3 - - 180 - 12-8 I 8 8 90 112 203 292 12-10 I 10 10 60 155 270 295 14-4 I 4 4 45 - - - 14-5 II 5 5 40 92 184 273 14-9S I 9 5 4 15 90 180 270 14-12 I 12 8 43 90 - - 14-15 I 15 14 17 110 155 234 14-18 I 18 18 15 90 180 270 14-19 I 19 19 30 165 315 - 16-8 II 8 8 54 152 180 331 16-23S I 23 22 1 158 270 - - 16-26 I 26 26 60 - 275 338 18-8 I 8 8 180 - - - 18-11S II 11 11 62 119 241 340 18-30S I 30 29 1 180 193 285 350 18-32 I 32 32 85 138 222 265 20-16 II 16 16 238 318 333 347 20-24S I 24 24 70 145 215 290 20-39 I 39 37 2 63 144 252 333 20-41 I 41 41 45 126 225 - 22-12S I 12 12 - - - - 22-19S I 19 19 15 90 225 308 22-21 II 21 21 16 135 175 349 22-32S I 32 32 72 145 215 288 22-41 I 41 27 14 39 135 264 - 22-55 I 55 55 30 142 226 314 22-95S I 32 26 6 26 180 266 - 24-19S II 19 19 30 165 315 - 24-31 I 31 31 90 225 255 - 24-61 I 61 61 90 180 270 324 Arrangements designated with an S are tooled in socket only. Read Less LAYOUTS BY NUMBER OF CONTACTS

Contacts 3 4 5 6 8 9

Shell Size/Layout 8-33 8-98 12-3 14-4 14-5 10-6 12-8 16-8 18-8 14-9S # of Contacts 3-#20 3-#20 3 #16 4-#12 5-#16 6-#20 8-#20 8-#16 8-#12 5-#20, 4-#12 Service Rating I I II I II I I II I I Contacts 10 11 12 15 16 18

Shell Size/Layout 12-10 18-11S 14-12 22-12S 14-15 20-16 14-18 # of Contacts 10-#20 11-#16 8-#20, 4-#16 12-#12 14-#20, 1-#16 16-#16 18-#20 Service Rating I II I I I II I Contacts 19 21 23 24

Shell Size/Layout 14-19 22-19S 24-19S 22-21 16-23S 20-24S # of Contacts 19-#20 19-#12 19-#12 21-#16 22-#20, 1-#16 24-#20 Service Rating I I II II I I Contacts 26 30 31 32

Shell Size/Layout 16-26 18-30S 24-31 18-32 22-32S 22-95S # of Contacts 26-#20 29-#20, 1-#16 31-#16 32-#20 32-#20, 1-#16 26-#20, 6-#12 Service Rating I I I I I I Contacts 39 41 55 61

Shell Size/Layout 20-39 20-41 22-41 22-55 24-61 # of Contacts 37-#20, 2-#16 41-#20 27-#20, 14-#16 55-#20 61-#20 Service Rating I I I I I Arrangements designated with an S are tooled in socket only. Read Less STEP 4: CONTACTSTEP 4: SELECT CONTACT

P = Pin STEP 5: ROTATIONSTEP 5: SELECT ROTATION

(Omit for normal) Rotations Layout Number W X Y Z 8-33 90 - - - 8-98 - - - - 10-6 90 - - - 12-3 - - 180 - 12-8 90 112 203 292 12-10 60 155 270 295 14-4 45 - - - 14-5 40 92 184 273 14-9S 15 90 180 270 14-12 43 90 - - 14-15 17 110 155 234 14-18 15 90 180 270 14-19 30 165 315 - 16-8 54 152 180 331 16-23S 158 270 - - 16-26 60 - 275 338 18-8 180 - - - 18-11S 62 119 241 340 18-30S 180 193 285 350 18-32 85 138 222 265 20-16 238 318 333 347 20-24S 70 145 215 290 20-39 63 144 252 333 20-41 45 126 225 - 22-12S - - - - 22-19S 15 90 225 308 22-21 16 135 175 349 22-32S 72 145 215 288 22-41 39 135 264 - 22-55 30 142 226 314 22-95S 26 180 266 - 24-19S 30 165 315 - 24-31 90 225 255 - 24-61 90 180 270 324 STEP 6: MODIFIERSTEP 6: SELECT MODIFIER

For other commercial modifications, i.e., less tools, with PC contact or end bell, please contact us. (omit for standard contacts) A15* = For use with B class for conductive black alloy finish |

|

CONTACTSAMPHENOL MB SERIES CONTACTS - PINS

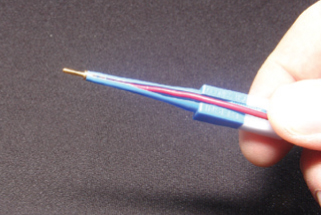

Color Bands Wire Insulation Range Contact Size Wire Size AWG Pin Contact 1 2 3 Wire Strip Lengths Min. Max. Wire Hole Filler Color 20 20,22 & 24 M39029/ Brown Brown Black .1875 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16, 18 & 20 M39029/ Brown Brown Brown .2812 (7.14) .053 (1.35) .103 (2.62) MS27488-16-2 Blue 12 12 & 14 M39029/ Brown Brown Orange .2812 (7.14) .097 (2.46) .158 (4.01) MS27488-12-2 Yellow 20 20,22 & 24 M39029/ Brown Orange Yellow .1875 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 20 20,22 & 24 M39029/ Brown Orange Green .1875 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 Fiber

MIL-T-29504/10 - - - - - - - - 12 Co-ax* - Contact Us - - - - - - - - AMPHENOL MB SERIES CONTACTS - SOCKETS

Color Bands Wire Insulation Range Contact Size Wire Size AWG Pin Contact 1 2 3 Wire Strip Lengths Min. Max. Wire Hole Filler Color 20 20,22 & 24 M39029/ Brown Brown Green .1875 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16, 18 & 20 M39029/ Brown Brown Blue .2812 (7.14) .053 (1.35) .103 (2.62) MS27488-16-2 Blue 12 12 & 14 M39029/ Brown Brown Grey .2812 (7.14) .097 (2.46) .158 (4.01) MS27488-12-2 Yellow 20 20,22 & 24 M39029/ Brown Yellow Black .1875 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 20 20,22 & 24 M39029/ Brown Yellow Brown .1875 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 Fiber

MIL-T-29504/11 - - - - - - - - 12 Co-ax* - Contact Us - - - - - - - - *Special – contact us for information. All dimensions in inches (millimeters in parentheses) CONTACT TOOLSAMPHENOL MB SERIES CONTACT TOOLS - PINS

Metal Plastic Contact Size Hand-Crimp Tool Power-Crimp Tool Turret Heads Use Locator Color Insertion Tool Extraction Tool Insertion/Extraction Tool Insertion Tip Color Extraction Tip Color 20 M22520/1-01 WA27FƗƗ M22520/1-02 Blue DAK83-20B DRK83-20B M81969/14-11 Red White 16 M22520/1-01 WA27FƗƗ M22520/1-02 Red DAK83-16B DRK83-16B M81969/14-03 Blue White 12 M22520/1-01 WA27FƗƗ M22520/1-02 Yellow DAK83-12B DRK83-12B M81969/14-04 Yellow White 20 - - - - - - - - - 20 - - - - - - - - - 20 Fiber - - - - - - - - - 20 Co-ax* - - - - - - - - - AMPHENOL MB SERIES CONTACT TOOLS - SOCKETS

Metal Plastic Contact Size Hand-Crimp Tool Power-Crimp Tool Turret Heads Use Locator Color Insertion Tool Extraction Tool Insertion/Extraction Tool Insertion Tip Color Extraction Tip Color 20 M22520/1-01 WA27FƗƗ M22520/1-02 Blue DAK83-20B DRK83-20B M81969/14-11 Red White 16 M22520/1-01 WA27FƗƗ M22520/1-02 Red DAK83-16B DRK83-16B M81969/14-03 Blue White 12 M22520/1-01 WA27FƗƗ M22520/1-02 Yellow DAK83-12B DRK83-12B M81969/14-04 Yellow White 20 Alumel* - - - - - - - - - 20 Chromel* - - - - - - - - - 20 Fiber Optic* - - - - - - - - - 20 Co-ax* - - - - - - - - - *Special – contact us for information. ƗƗ Contact us for more tool accessories. All dimensions in inches (millimeters in parentheses) |

|

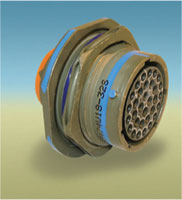

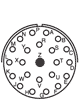

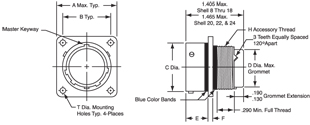

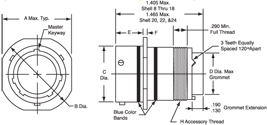

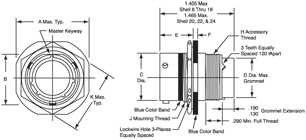

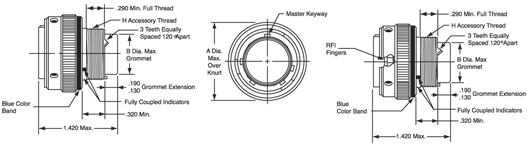

RECEPTACLESAMPHENOL MB SERIES RECEPTACLES

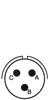

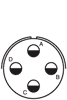

MB10 (MS3470) MB11 (MS3472) MB13 (MS3471)

B Dia.

Shell Size MS3470/ MS3472/ MS3470/ MS3472/ MS3471/ C D MS3470/ MS3472/ F ± .016 H Thread Class 2A MS3470/ MS3472/ 8 0.828 (21.0) 1.065 (27.1) 0.594 (15.1) 0.734 (18.6) 0.938 (23.8) 0.471 (12.0) 0.305 (7.7) .462/.431 .493/.462 0.062 (1.6) .5000-20 UNF 0.120 (3.0) 0.150 (3.8) 10 0.954 (24.2) 1.141 (29.0) 0.719 (18.3) 0.812 (20.6) 1.062 (27.0) 0.588 (14.9) 0.405 (10.3) .462/.431 .493/.462 0.062 (1.6) .6250-24 UNEF 0.120 (3.0) 0.150 (3.8) 12 1.047 (26.6) 1.266 (32.2) 0.812 (20.6) 0.938 (23.8) 1.156 (29.4) 0.748 (19.0) 0.531 (13.5) .462/.431 .493/.462 0.062 (1.6) .7500-20 UNEF 0.120 (3.0) 0.150 (3.8) 14 1.141 (29.0) 1.360 (34.5) 0.906 (23.0) 1.031 (26.2) 1.250 (31.8) 0.873 (22.2) 0.665 (16.9) .462/.431 .493/.462 0.062 (1.6) .8750-20 UNEF 0.120 (3.0) 0.150 (3.8) 16 1.234 (31.3) 1.453 (36.9) 0.969 (24.6) 1.125 (28.6) 1.344 (34.1) 0.998 (25.3) 0.790 (20.1) .462/.431 .493/.462 0.062 (1.6) 1.0000-20 UNEF 0.120 (3.0) 0.150 (3.8) 18 1.328 (33.7) 1.532 (38.9) 1.062 (27.0) 1.203 (30.6) 1.438 (36.5) 1.123 (28.5) 0.869 (22.1) .462/.431 .493/.462 0.062 (1.6) 1.0625-18 UNEF 0.120 (3.0) 0.150 (3.8) 20 1.453 (36.9) 1.688 (42.9) 1.156 (29.4) 1.297 (32.9) 1.562 (39.7) 1.248 (31.7) 0.994 (25.2) .587/.556 .587/.556 0.094 (2.4) 1.1875-18 UNEF 0.120 (3.0) 0.150 (3.8) 22 1.578 (40.1) 1.766 (44.9) 1.250 (31.8) 1.375 (34.9) 1.688 (42.9) 1.373 (34.9) 1.119 (28.4) .587/.556 .587/.556 0.094 (2.4) 1.3125-18 UNEF 0.120 (3.0) 0.150 (3.8) 24 1.703 (43.3) 1.891 (48.0) 1.375 (34.9) 1.500 (38.1) 1.812 (46.0) 1.498 (38.0) 1.244 (31.6) .620/.589 .620/.589 0.094 (2.4) 1.4375-18 UNEF 0.147 (3.7) 0.150 (3.8) AMPHENOL MB SERIES JAM NUT RECEPTACLES

MB14 (MS3474) Shell Size A Max B±.005 (±0.127) C Diameter ±.003 (±0.076) D Diameter Max. E Max./Min. F Max./Min. H Thread Class 2A K Max. J Mounting ThreadClass 2A 8 0.954 (24.2) 0.525 (13.3) 0.471 (12.0) 0.305 (7.7) .707/.658 (17.9/ .113/.086 (2.8/2.1) .5000-20 UNF 0.767 (19.5) .5625-24 UNEF 10 1.078 (27.4) 0.650 (16.5) 0.588 (14.9) 0.405 (10.3) .707/.658 (17.9/ .113/.086 (2.8/2.1) .6250-24 UNEF 0.892 (22.7) .6875-24 UNEF 12 1.266 (32.2) 0.813 (20.7) 0.748 (19.0) 0.531 (13.5) .707/.658 (17.9/ .113/.086 (2.8/2.1) .7500-20 UNEF 1.079 (27.4) .8750-20 UNEF 14 1.391 (35.3) 0.937 (23.8) 0.873 (22.2) 0.665 (16.9) .707/.658 (17.9/ .113/.086 (2.8/2.1) .8750-20 UNEF 1.205 (30.6) 1.0000-20 UNEF 16 1.516 (38.5) 1.061 (26.9) 0.998 (25.3) 0.790 (20.1) .707/.658 (17.9/ .113/.086 (2.8/2.1) 1.0000-20 UNEF 1.329 (33.8) 1.1250-18 UNEF 18 1.641 (41.7) 1.186 (30.1) 1.123 (28.5) 0.869 (22.1) .707/.658 (17.9/ .113/.086 (2.8/2.1) 1.0625-18 UNEF 1.455 (37.0) 1.2500-18 UNEF 20 1.828 (46.4) 1.311 (33.3) 1.248 (31.7) 0.994 (25.2) .772/.721 (19.6/ .148/.096 (3.7/2.4) 1.1875 UNEF 1.579 (40.1) 1.3750 UNEF 22 1.954 (49.6) 1.436 (36.5) 1.373 (34.9) 1.119 (28.4) .772/.721 (19.6/ .148/.096 (3.7/2.4) 1.3125-18 UNEF 1.705 (43.3) 1.5000-18 UNEF 24 2.078 (52.8) 1.561 (39.6) 1.498 (38.0) 1.244 (31.6) .772/.721 (19.6/ .148/.096 (3.7/2.4) 1.4375-18 UNEF 1.829 (46.5) 1.6250-18 UNEF All dimensions in inches (millimeters in parentheses) PLUGSAMPHENOL MB SERIES PLUGS

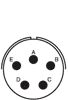

MB16 (MS3476) MB18 (MS3475)

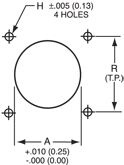

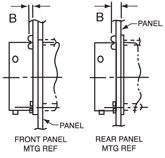

Shell Size A Diameter Max. B Diameter Max. H Thread Class 2A 8 0.782 (19.9) 0.305 (7.7) .5000-20 UNF 10 0.926 (23.5) 0.405 (10.3) .6250-24 UNEF 12 1.043 (26.5) 0.531 (13.5) .7500-20 UNEF 14 1.183 (30.0) 0.665 (16.9) .8750-20 UNEF 16 1.305 (33.1) 0.790 (20.1) 1.0000-20 UNEF 18 1.391 (35.3) 0.869 (22.1) 1.0625-18 UNEF 20 1.530 (38.9) 0.994 (25.2) 1.1875-18 UNEF 22 1.656 (42.1) 1.119 (28.4) 1.3125-18 UNEF 24 1.777 (45.1) 1.244 (31.6) 1.4375-18 UNEF All dimensions in inches (millimeters in parentheses) PANEL THICKNESS & CUTOUTSAMPHENOL MB SERIES MB FLANGED PANEL CUTOUTS

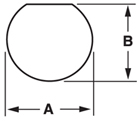

MS3470 (MB10) MS3470/MB10 Narrow Flange MS3472/MB11 Wide Flange Shell Size A Diameter R Screw H Size R Screw H Size 8 .620 (15.7) .594 (15.0) .125 (3.1) #4 .734 (18.6) .155 (3.9) #6 10 .740 (18.8) .719 (18.2) .125 (3.1) #4 .812 (20.6) .155 (3.97) #6 12 .864 (21.9) .812 (20.6) .125 (3.1) #4 .938 (23.9) .155 (3.97) #6 14 .990 (25.1) .906 (23.0) .125 (3.1) #4 1.031 (26.1) .155 (3.97) #6 16 1.118 (28.4) .969 (24.6) .125 (3.1) #4 1.125 (28.5) .155 (3.97) #6 18 1.240 (31.5) 1.062 (26.9) .125 (3.1) #4 1.203 (30.5) .155 (3.97) #6 20 1.366 (34.7) 1.156 (29.3) .125 (3.1) #4 .812 (20.6) 1.297 (32.9) #6 22 1.490 (37.8) 1.250 (31.7) .125 (3.1) #4 1.375 (34.9) .155 (3.97) #6 24 1.616 (41.0) 1.375 (34.9) .155 (3.9) #6 1.500 (38.1) .155 (3.97) #6 For MS3470/MB10 gaskets. For nut plates and seal screws. AMPHENOL MB SERIES JAM NUT PANEL CUTOUTS

MS3474 (MB14) Shell Size A Diameter ±.005 (±0.13) B±.005 (±0.13) 8 .572 (15.5) .536 (13.6) 10 .697 (17.7) .661 (16.7) 12 .895 (22.7) .824 (20.9) 14 1.010 (25.6) .948 (24.0) 16 1.135 (28.3) 1.072 (27.2) 18 1.260 (32.0) 1.197 (30.4) 20 1.385 (35.1) 1.322 (33.5) 22 1.510 (38.3) 1.447 (36.7) 24 1.635 (41.5) 1.572 (39.9) AMPHENOL MB SERIES PANEL THICKNESS

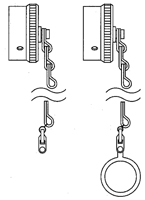

MS3470 (MB10) Narrow Flange Narrow Flange MS3470/MB10 Wide Flange MS3472/MB11 Shell Size *B Max. 8 10 12 14 16 18 0.087 (2.2) .118 (3.0) 20 22 24 .212 (5.3) .212 (5.3) * (Screw head front-mount or panel thickness plus screw head rear-mount) AMPHENOL MB SERIES DUMMY RECEPTACLES & METAL DUST CAPS

Dummy Receptacles Metal Dust Caps Shell Size Chain Dummy Receptacle For Plug For Receptacle For Receptacle 8 MS3115-8 MS3180-8CA MS3181-8CA MS3181-8NA 10 MS3115-10 MS3180-10CA MS3181-10CA MS3181-10NA 12 MS3115-12 MS3180-12CA MS3181-12CA MS3181-12NA 14 MS3115-14 MS3180-14CA MS3181-14CA MS3181-14NA 16 MS3115-16 MS3180-16CA MS3181-16CA MS3181-16NA 18 MS3115-18 MS3180-18CA MS3181-18CA MS3181-18NA 20 MS3115-20 MS3180-20CA MS3181-20CA MS3181-20NA 22 MS3115-22 MS3180-22CA MS3181-22CA MS3181-22NA 24 MS3115-24 MS3180-24CA MS3181-24CA MS3181-24NA ** Sash chain for mounting screw on flanged receptacles. Sash chain with ring for mounting to jam nut receptacle. Dust caps are anodized-plated. All dimensions in inches (millimeters in parentheses) |

|

AMPHENOL MB SERIES ACCESSORIES

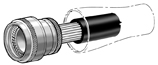

STANDARD CABLE CLAMPS

Straight Clamp 90° Cable Entry Shell Size Low Cost Self-Locking Low Cost Self Locking Max. Min. 8 M85049/52-1-8* M85049/52S8* M85049/51-1-8* M85049/51S8* .204 (5.18) .125 (3.18) 10 M85049/52-1-10* M85049/52S10* M85049/51-1-10* M85049/51S10* .286 (7.26) .187 (4.75) 12 M85049/52-1-12* M85049/52S12* M85049/51-1-12* M85049/51S12* .416 (10.57) .291 (7.39) 14 M85049/52-1-14* M85049/52S14* M85049/51-1-14* M85049/51S14* .476 (12.09) .351 (8.92) 16 M85049/52-1-16* M85049/52S16* M85049/51-1-16* M85049/51S16* .625 (15.88) .501 (12.72) 18 M85049/52-1-18* M85049/52S18* M85049/51-1-18* M85049/51S18* .706 (17.93) .518 (13.16) 20 M85049/52-1-20* M85049/52S20* M85049/51-1-20* M85049/51S20* .831 (21.11) .581 (14.76) 22 M85049/52-1-22* M85049/52S22* M85049/51-1-22* M85049/51S22* .956 (24.28) .644 (16.36) 24 M85049/52-1-24* M85049/52S24* M85049/51-1-24* M85049/51S24* 1.081 (27.46) .706 (17.93) * Select plating code to match connector plating N = Electroless nickle W = Olive drab chromate over cadmium over electroless nickle (500-hour salt spray)

Part Number

M85049/60 X

Environmental M85049/7 M85049/9 M85049/11 X X X

EMI/RFI Non-Environmental M85049/23 M85049/24 M85049/25 X X X

EMI/RFI Environmental M85049/6 M85049/8 M85049/10 X X X

EMI/RFI Crimp Ring M85049/26 X

EMI/RFI Banding M85049/82 M85049/83 M85049/84 X X X

Cable Tie M85049/55 M85049/53 M85049/54 X X X

Wire Seal Compression Nuts “E” M85049/31 X NOTE: If military-standard versions won’t work for your applications, please contact us with your requirements. All dimensions in inches (millimeters in parenthesis) |

|

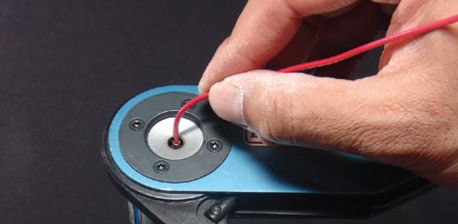

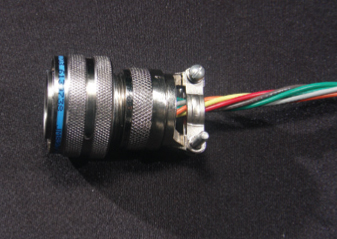

WIRE-STRIPPING AND CONTACT-CRIMPINGAMPHENOL MB SERIES WIRE-STRIPPING AND CONTACT-CRIMPING

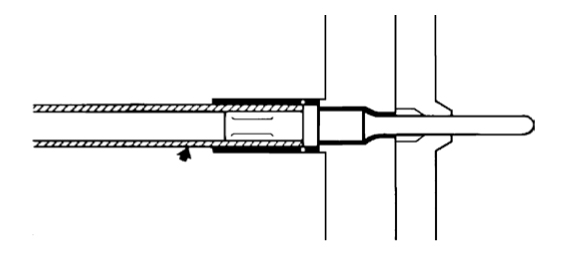

STEP 1: Strip wires. (See above for correct strip length by contact.) Insert wire into rear of contact. Wire insulation must push against rear of contact. Wire must be visible through inspection hole. STEP 2: Use M22520/1-01 crimp tool with proper crimp locator M22520/1-02. Click here for additional tooling. Contact Size Color 20 Red 16 Blue 12 Yellow STEP 3: Insert contact and wire into tool jaws. To crimp, squeeze handles together fully until ratchet releases and allows handles to expand; otherwise, contact cannot be extracted from tool jaws. Maintain slight insertion pressure on wire while crimping contact to wire. IMPORTANT NOTE: Microsection the contact to verify crimp quality. CONTACT INSERTIONAMPHENOL MB SERIES CONTACT INSERTION

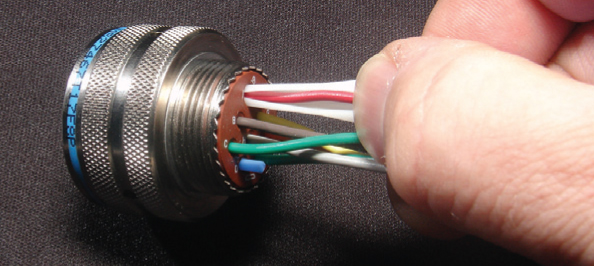

STEP 1: Remove backshell and put wired contacts through cable clamp opening. STEP 2: Use colored end of CIET tool for insertion. Place wire into tool at large opening. To facilitate contact insertion, a six-inch minimum of free wire is recommended. STEP 3: Slide back tool on wire while holding thumb against wire at opening. Wire will slip into tool.

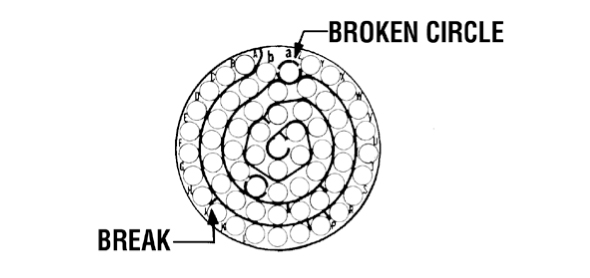

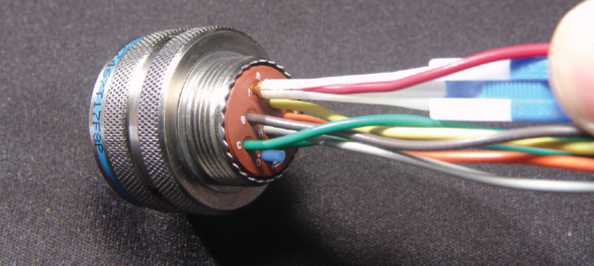

STEP 4: With tool pressed against shoulder of contact, starting at the center cavity, insert wired contact and tool into properly-identified cavity at rear of plug with firm, even pressure. Do not use excessive pressure. STEP 5: When contact touches bottom, a slight click can be heard as tines of metal retaining clip snap into place behind contact shoulder. STEP 6: Check face of plug or receptacle for proper contact installation. In socket inserts with a large number of contacts, cavities are identified in a spiral pattern. A projecting line from the spiral indicates omission of a letter; a broken circle around a cavity indicates transition between capitals, and lower case and double letters. STEP 7: Withdraw tool from rear of plug. To be sure that contact is locked, pull back lightly on wire. Remove tool from wire and proceed with other contacts. STEP 8: After all contacts are inserted, fill unwired cavities with sealing plugs (insert head first and leave end protruding for ease of removal), assemble backshell on rear of connector.

CONTACT EXTRACTIONAMPHENOL MB SERIES CONTACT EXTRACTION

STEP 1: Remove backshell and slide back along wires to allow access. To extract a contact, use white end of CIET tool. Place wire into tool at large opening. Slide back tool on wire while holding thumb against wire at opening. Wire will slip into tool. STEP 2: Push tool into rear of plug until it touches bottom. At this point, tool releases tines on retaining clip so that contact can be extracted. STEP 3: While maintaining slight insertion force on tool, firmly hold wire against serrated shoulder at center of tool and extract both wired contact and tool from plug.

|

Philadelphia

19116

Click here for the contact information of the branch nearest you.