Amphenol PT / PT-SE Connectors (MIL-DTL-26482 Series I)

EXTREME EXPOSURE MINI-CIRCULAR CONNECTORS

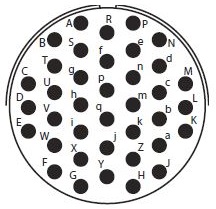

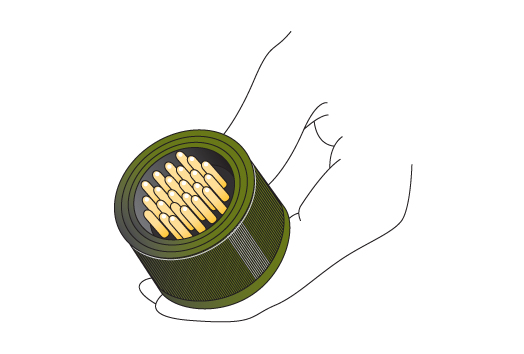

The Amphenol PT series and PT-SE series connectors (MIL-DTL-26482 Series I) provide high-density contact arrangements in a circular shell. Amphenol PT series connectors offer solder contacts, PT-SE offers high-performance crimp contacts, and PT-CE offers a commercial crimp option. These circular Amphenol PT series connectors provide quick-disconnect bayonet coupling for rapid mating and unmating, and several mounting styles and shell sizes. For full product details on Amphenol PT, PT-CE and PT-SE series connectors, see our specifications below.

Get shopping! Mil Spec prefixes include MS3110, MS3112, MS3114, MS3116, MS3119, MS3120, MS3122, MS3124 and MS3126. Amphenol proprietary prefix is PT.

|

FEATURESAMPHENOL PT/PT-SE SERIES FEATURES

MATERIALS & FINISHESAMPHENOL PT/PT-SE SERIES MATERIALS & FINISHES

Shell Aluminum Alloy

Shell Plating Cadmium, Anodized, Electroless Nickel,

Zinc Alloy, or Grey Zinc Nickel

Contacts Copper alloy

Contact Platings Gold-plated, 50 microinches minimum per MIL-G-45204 type II.

Insulator Resilient neoprene. PT-SE and PT-CE insulators encase a tough plastic wafer with contact retention tines for high-reliability retention of crimp contacts.

ELECTRICAL DATAAMPHENOL PT/PT-SE SERIES ELECTRICAL DATA

Operating Voltage/Test VoltageMaximum Operating Voltage Test Voltage Service Rating* Test Altitude DC AC (RMS) DC AC (RMS) 1 2

850 1,400 600 1,000 2,100 3,200 1,500 2,300 1 2

400 600 300 450 535 700 375 500 * Each insulator layout has a specific “service rating.” See here for solder, and here for crimp. Current Rating Contact Size Rated Current Amps Test Current Amps (Working) Potential Drop (Millivolts) Initial 20 13 7.5 16 22 13 12 41 23 Wire Range Sizes 24 to 12 AWG (and co-ax)

Contact Resistance When tested to MIL-STD-1344 Method 3004, will not exceed voltage drops listed in table. Consult MIL-DTL-26482, 3.6.4 for details.

Insulation Resistance 5,000 megohms minimum at 77˚F (25˚C)

MECHANICALAMPHENOL PT/PT-SE SERIES MECHANICAL

Operating Temperature -67˚F to +257˚F (-55˚C to +125˚C)

Sealing 48 hours in 6 feet of water per MIL-DTL-26482 4.6.14. Meets 10- and 20-day 50-95% humidity testing per MIL-STD-1344 Method 1002.2 per MIL-DTL-26482; Solder Only

Crimp: should have contacts installed in all positions when the connector is wired. Sealing plugs should be installed in the grommet holes when no wire is attached to the contact. Wire Sealing Range Per MIL-DTL-26482 1.4

Insulation Outside Diameter Limits: Inches (MM) Contact Size AWG Size Min. (PT) Min. (PT-SE/PT-CE) Max. (PT/PT-SE/PT-CE) 20 24, 22, and 20 .047 (1.19) .047 (1.19) .083 (2.11) 16 20, 18, and 16 .066 (1.68) .066 (1.68) .109 (2.77) 12 12 and 14 .097 (2.46) .097 (2.46) .142 (3.61) Insulation Strip Length

Contact Size Wire Size (AWG) Strip Length Inches (MM) 20 20-24 .275 (7.0) 16 16-20 .250 (6.4) 12 12-14 .250 (6.4) Mating Life 500 cycles minimum per MIL-DTL-26482 3.6.17

Salt Spray Unmated connectors and protective covers meet 48-hour exposure to MIL-STD-1344 Method 1001 per MIL-DTL-26482. (Cadmium plating) Olive drab/black zinc, electroless nickel meets 48-hour salt spray test, gray zinc nickel meets 500-hour salt spray test.

Heat +221˚F (+105˚C) for 1,000 hours per MIL-DTL-26482

Chemical Resistance 20-hour full-immersion unmated in hydraulic fluid and lubricating oil per MIL-DTL-26482.

Vibration 10 to 2,000Hz (15g’s) 10 microseconds maximum discontinuity. To MIL-STD-1344 Method 2005 per MIL-DTL-26482.

Shock 50g’s, 11ms duration, three major axes. 10 microseconds maximum discontinuity. To MIL-STD-1344 Method 2004 per MIL-DTL-26482.

Contact Type Solder, crimp, printed circuit, co-ax,

high voltage, first-mate last-break

Number of Circuits PT: 1 to 61; PT-SE & PT-CE: 2 to 61

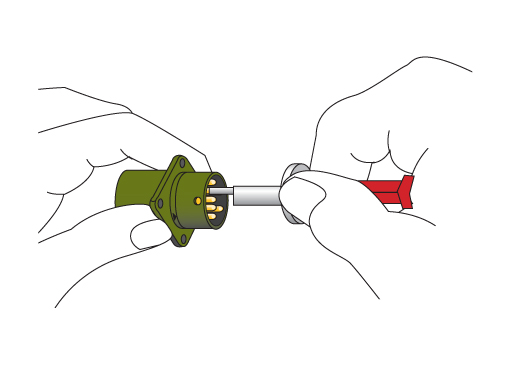

Contact Insertion (Crimp) Insertion from the rear of connector with simple hand-tool. Front release with appropriate extraction tool.

Contact Retention To MIL-STD-1344 Method 2007 per MIL-DTL-26482.

Contact Size Axial Load Min. Lbs 20 15 (66.7) 12 and 16 25 (111.2) Polarization Five keyway, three-point bayonet with optional rotational polarization. See here for solder, and here for crimp.

Approvals MIL-DTL-26482 Series I

UL #E115497 VG95328 or HE301 All dimensions in inches (millimeters in parentheses) AMPHENOL PT/PT-SE SERIES EXERPT FROM MIL-DTL-26482H

3.7.4 JAN and J Marking. The United States Government has adopted and is exercising legitimate control over the certification marks “JAN” and “J”, respectively, to indicate that items so marked or identified are manufactured to, and meet all the requirements of specifications. Accordingly, items acquired to, and meeting all of the criteria specified herein and in applicable specifications shall bear the certification mark “JAN” except that items too small to bear the certification mark “JAN” shall bear the letter “J”. The “JAN” or “J” shall be placed immediately before the PIN except that if such location would place a hardship on the manufacturer in connection with such marking, the “JAN” or “J” may be located on the first line above or below the PIN. Items furnished under contracts or orders which either permit or require deviation from the conditions or requirements specified herein or in applicable specifications shall not bear “JAN” or “J”. In the event an item fails to meet the requirements on this specification and the applicable specification sheets, the manufacturer shall remove completely the military PIN and the “JAN” or the “J” from the sample tested and also from all items represented by the sample. The “JAN” or “J” certification mark shall not be used on products acquired to contractor drawings or specification. The United States Government has obtained Certificate of Registration Number 504,860 for the certification mark “JAN” and Registration Number 1,586,261 for the certification mark “J”. COMPONENTSAMPHENOL PT/PT-SE SERIES COMPONENTS

Plugs Receptacles PT PTSE PT PTSE

|

|

AMPHENOL PT/PT-SE SERIES APPLICATIONS

|

|

STEP 1: SHELLAMPHENOL PT/PT-SE SERIES MILITARY PART NUMBER EXAMPLE

1 2 3 4 5 MS3116º Fº 16-26 P W SHELL STYLE ENDBELL LAYOUT CONTACT ROTATION AMPHENOL PT/PT-SE SERIES COMMERCIAL PART NUMBER EXAMPLE

1 2 3 4 5 6 PT06* E* 16-26 P W -SR SHELL STYLE ENDBELLS LAYOUT CONTACT ROTATION MODIFIER STEP 1: SELECT SHELL STYLE, PLUG OR RECEPTACLE

PT02E*

PT07A*

PTB*

PT06*

PT08E-SR*

PT00*

PT01*

PT07* PART NUMBER KEY: Commercial=(*) Commercial & Military=(††) Military Only=(°) STEP 2: ENDBELLSTEP 2: SELECT ENDBELL

A* E†† A-(SR)* J†† W* P†† Commercial=(*) Commercial & Military=(††) Military Only=(°) STEP 3: LAYOUTSTEP 3: SELECT LAYOUT

Contacts Rotations Layout Service Rating Total 20 16 12 Coax W X Y Z 6-1* I 1 1 - - - - 8-2†† I 2 2 58 122 - - 8-3†† I 3 3 60 210 - - 8-4†† I 4 4 45 97# 184# - 8-33* I 3 3 90 - - - 8-98* I 3 3 - - - - 10-2* I 2 2 45 90 315 - 10-5* I 5 5 45 151 180 270 10-6†† I 6 6 90 - - - 10-98†† I 6 6 90 180 240 270 12-3†† II 3 3 - - 180 - 12-4* I 4 4 38 - - - 12-8†† I 8 8 90 112 203 292 12-10†† I 10 10 60 155 270 295 12-14 A* I 14 14 - - - - 14-4 AS* I 4 4 45 - - - 14-AA*u I 4 4 45 - - - 14-5†† II 5 5 40 92 184 273 14-12†† I 12 8 4 43 90 - - 14-15†† I 15 14 1 17 110 155 234 14-18†† I 18 18 15 90 180 270 14-19†† I 19 19 30 165 315 - 14-91* HV 5k 3 3 - 60 - - 16-8†† II 8 8 54 152 180 331 16-23†† I 23 22 1 158 270 - - 16-26†† I 26 26 60 - 275 338 16-70 Coax 15 14 1 - - - - 16-99†† I 23 21 2 1 66 156 223 340 18-5* II 5 5 55 97 263 315 18-11†† II 11 11 62 119 241 340 18-30†† I 30 29 1 180 193 285 350 18-32†† I 32 32 85 138 222 265 20-16†† II 16 16 238 318 333 347 20-24†† I 24 24 70 145 215 290 20-25* I 25 25 72 144 216 288 20-27†† I 27 27 72 144 216 288 20-39†† I 39 37 2 63 144 252 333 20-41†† I 41 41 45 126 225 - 20-90* HV 7 7 45 135 225 315 22-21†† II 21 21 16 135 175 349 22-32†† I 32 32 72 145 215 288 22-34* I 34 34 62 142 218 298 22-36* I 36 36 72 144 216 288 22-41†† I 41 27 14 39 135 216 265 22-55†† I 55 55 30 142 226 314 24-31A* I 31 31 90 225 255 - 24-31A* I 61 61 90 180 270 324 PART NUMBER KEY: Commercial=(*) Commercial & Military=(††) # = Commercial Rotation Only (Not Military) A = A-Class Only S = Socket Insert Only u = 14-AA Insert Follows 14-4 MIL-STD-1669A contact spacing Read Less LAYOUTS BY NUMBER OF CONTACTS

CONTACT

SERIES

U = 14-44 Contacts 1 2 3 4

Shell Size/Layout 6-1 8-2 10-2 8-3 8-33 8-98 12-3 14-91 8-4 12-4 14-4S # of Contacts 1-#20 2-#20 2 #16 3-#20 3-#20 3-#20 3-#16 3-HV 4-#20 4-#16 4-#12 Series

Service Rating I I I I I I II HV5k I I I Contacts 4 5 6

Shell Size/Layout 14-AAU 18-76 10-5 14-5 14-22 18-5 10-6 10-98 18-91 # of Contacts 4-#12 4(coax) 5-#20 5-#16 4-#12; 5-#12 6-#20 6-#20 6-HV Series

Service Rating I (coax) I II I II I I HV5k Contacts 7 8

Shell Size/Layout 20-90 22-7 22-78 22-96 12-8 16-8 # of Contacts 7-HV 7(coax) 7(coax) 7-#12 8-#20 8-#16 Series

Service Rating I II HV5k I I I Contacts 8 9 10 11 12

Shell Size/Layout 18-80 22-71 12-10 18-11 14-12 # of Contacts 6-#20; 2(coax) 2-#20; 7(coax) 10-#20 11-#16 4-#16; 8-#20 Series

Service Rating II/(coax) (coax) I II I Contacts 14 15 16 18

Shell Size/Layout 12-14 16-76 20-70 14-15 16-70 20-16 14-18 # of Contacts 14-#20 5-#12; 10-#20; 4(coax) 1-#16; 1-#12(coax); 16-#16 18-#20 Series

Service Rating I Size 12 (coax) I II not rated I I Contacts 19 21 23 24 25

Shell Size/Layout 14-19 22-21 16-23 16-99 20-24 20-25 # of Contacts 19-#20 21-#16 1-#16; 22-#20 2-#16; 21-#20 24-#20 25-#20 Series

Service Rating I II I I I I Contacts 25 26 27 24 25

Shell Size/Layout 22-25 16-26 20-27 18-30 24-31 # of Contacts 25-#16 26-#20 27-#20 1-#16; 29-#20 31-#16 Series

Service Rating I I I I I Contacts 32 34 36 39

Shell Size/Layout 18-32 22-32 22-34 22-36 20-39 # of Contacts 32-#20 32-#20 34-#20 36-#20 2-#16 37-#20 Series

Service Rating I I I I I Contacts 41 51 55 61

Shell Size/Layout 20-41 22-41 24-51 22-55 24-61 # of Contacts 41-#20 14-#16; 27-#20 4-#12(coax); 47-#20 55-#20 61-#20 Series

Service Rating I I I I I Read Less STEP 5: ROTATIONSTEP 5: SELECT ROTATION

See Layout Chart on Step 3 (Omit for normal) Rotations Layout W X Y Z 6-1* - - - - 8-2†† 58 122 - - 8-3†† 60 210 - - 8-4†† 45 97# 184# - 8-33* 90 - - - 8-98* - - - - 10-2* 45 90 315 - 10-5* 45 151 180 270 10-6†† 90 - - - 10-98†† 90 180 240 270 12-3†† - - 180 - 12-4* 38 - - - 12-8†† 90 112 203 292 12-10†† 60 155 270 295 12-14 A* - - - - 14-4 AS* 45 - - - 14-AA*u 45 - - - 14-5†† 40 92 184 273 14-12†† 43 90 - - 14-15†† 17 110 155 234 14-18†† 15 90 180 270 14-19†† 30 165 315 - 14-91* - 60 - - 16-8†† 54 152 180 331 16-23†† 158 270 - - 16-26†† 60 - 275 338 16-70 - - - - 16-99†† 66 156 223 340 18-5* 55 97 263 315 18-11†† 62 119 241 340 18-30†† 180 193 285 350 18-32†† 85 138 222 265 20-16†† 238 318 333 347 20-24†† 70 145 215 290 20-25* 72 144 216 288 20-27†† 72 144 216 288 20-39†† 63 144 252 333 20-41†† 45 126 225 - 20-90* 45 135 225 315 22-21†† 16 135 175 349 22-32†† 72 145 215 288 22-34* 62 142 218 298 22-36* 72 144 216 288 22-41†† 39 135 216 265 22-55†† 30 142 226 314 24-31A* 90 225 255 - 24-31A* 90 180 270 324 PART NUMBER KEY: Commercial=(*) Commercial & Military=(††) # = Commercial Rotation Only (Not Military) A = A-Class Only S = Socket Insert Only u = 14-AA Insert Follows 14-4 MIL-STD-1669A contact spacing STEP 6: MODIFIERSTEP 6: SELECT MODIFIER

SR* = F-Style Strain Relief (not military) 002* = Black Anodized 005* = Anodic Coating (Alumilite) 014* = Olive Drab Chromate over Cadmium over Nickel (500-hour salt spray) 023* = Electroless Nickel (RoHS) 024* = Olive Drab Zinc Alloy 025* = Black Alloy (RoHS) 027* = Conductive Black Alloy (RoHS) 072 = Gray Zinc Nickel (RoHS) 424* = Electroless Nickel and Strain Relief (SR & 023) (RoHS) 466* = Olive Drab Zinc Alloy with Strain Relief (SR & 024) 470* = Black Alloy with Strain Relief (SR & 025) (RoHS) 476* = Conductive Black Zinc Alloy with Strain Relief (SR & 027) (RoHS) SCC* = Self-Closing Cap Box Mount (02) Shell sizes 8,10, 12 & 18 only LC = Less Contacts Commercial=(*) |

|

STEP 1: SHELLAMPHENOL PT/PT-SE SERIES MILITARY PART NUMBER EXAMPLE

1 2 3 4 5 MS3126º Fº 16-26 P W SHELL STYLE FINISH LAYOUT CONTACT ROTATION AMPHENOL PT/PT-SE SERIES COMMERCIAL PART NUMBER EXAMPLE

1 2 3 4 5 6 PT06* SE* 16-26 P W -SR SHELL STYLE ENDBELLS LAYOUT CONTACT ROTATION MODIFIER STEP 1: SELECT SHELL STYLE, PLUG OR RECEPTACLE

PT02SE*

PT00*

PT06*

PT08SE-SR*

PT01*

PT07* PART NUMBER KEY: SE=(*) CE=(††) Military=(°) STEP 2: ENDBELLSTEP 2: SELECT ENDBELL

SE* SE-(SR)* SP* SE=(*) CE=(††) Military=(°) STEP 3: LAYOUTSTEP 3: SELECT LAYOUT

Contacts Insert Rotations Layout Service Rating Total 20 16 12 12 Coax 8 Coax W X Y Z 8-2†† I 2 2 58 122 - - 8-3†† I 3 3 60 210 - - 8-4†† I 4 4 45 97# 184# - 8-33*º I 3 3 90 - - - 10-6††*º I 6 6 90 - - - 10-98†† I 6 6 90 180 240 270 12-3††*º II 3 3 - - 180 - 12-8††*º I 8 8 90 112 203 292 12-10††*º I 10 10 60 155 270 295 14-5††*º II 5 5 40 92 184 273 14-12††*º I 12 8 4 43 90 - - 14-15††*º I 15 14 1 17 110 155 234 14-18††*º I 18 18 15 90 180 270 14-19††*º I 19 19 30 165 315 - 14-22* I 5 1 4 45 - - - 14-91* HV 5k 3 3 - 60 - - 16-8††*º II 8 8 54 152 180 331 16-23††*º I 23 22 1 158 270 - - 16-26††*º I 26 26 60 - 275 338 16-76* Coax 14 8 1 5 - - - - 16-99*º I 23 21 2 1 66 156 223 340 18-5††* II 5 5 55 97 263 315 18-11††* II 11 11 62 119 241 340 18-30††*º I 30 29 1 180 193 285 350 18-32††*º I 32 32 85 138 222 265 18-80†† I/Coax 8 6 2 45 90 135 160 18-91††* HV 5k 6 6 90 180 240 270 20-16††*º II 16 16 238 318 333 347 20-27†† I 27 27 72 144 216 288 20-39††*º I 39 37 2 63 144 252 333 20-41††*º I 41 41 45 126 225 - 22-7* Coax 7 7 19 41 - - 22-21††*º II 21 21 16 135 175 349 22-25* I 25 25 60 125 211 336 22-32†† I 32 32 72 145 215 288 22-34†† I 34 34 62 142 218 298 22-36†† I 36 36 72 144 216 288 22-41††*º I 41 27 14 39 135 264 - 22-55††*º I 55 55 30 142 226 314 22-78* Coax 7 7 19 41 - - 22-96* II 7 7 19 41 - - 24-31†† I 31 31 90 225 255 - 24-38 I 38 38 85 138 222 265 24-51* I/Coax 51 47 4 22 171 313 - 24-61††*º I/Coax 61 61 90 180 270 324 PART NUMBER KEY: SE= (*) CE= (††) Military= (º) # = Commercial Rotation Only (Not Military) Read Less LAYOUTS BY NUMBER OF CONTACTS

CONTACT

SERIES

U = 14-44 Contacts 1 2 3 4

Shell Size/Layout 6-1 8-2 10-2 8-3 8-33 8-98 12-3 14-91 8-4 12-4 14-4S # of Contacts 1-#20 2-#20 2 #16 3-#20 3-#20 3-#20 3-#16 3-HV 4-#20 4-#16 4-#12 Series

Service Rating I I I I I I II HV5k I I I Contacts 4 5 6

Shell Size/Layout 14-AAU 18-76 10-5 14-5 14-22 18-5 10-6 10-98 18-91 # of Contacts 4-#12 4(coax) 5-#20 5-#16 4-#12; 5-#12 6-#20 6-#20 6-HV Series

Service Rating I (coax) I II I II I I HV5k Contacts 7 8

Shell Size/Layout 20-90 22-7 22-78 22-96 12-8 16-8 # of Contacts 7-HV 7(coax) 7(coax) 7-#12 8-#20 8-#16 Series

Service Rating I II HV5k I I I Contacts 8 9 10 11 12

Shell Size/Layout 18-80 22-71 12-10 18-11 14-12 # of Contacts 6-#20; 2(coax) 2-#20; 7(coax) 10-#20 11-#16 4-#16; 8-#20 Series

Service Rating II/(coax) (coax) I II I Contacts 14 15 16 18

Shell Size/Layout 12-14 16-76 20-70 14-15 16-70 20-16 14-18 # of Contacts 14-#20 5-#12; 10-#20; 4(coax) 1-#16; 1-#12(coax); 16-#16 18-#20 Series

Service Rating I Size 12 (coax) I II not rated I I Contacts 19 21 23 24 25

Shell Size/Layout 14-19 22-21 16-23 16-99 20-24 20-25 # of Contacts 19-#20 21-#16 1-#16; 22-#20 2-#16; 21-#20 24-#20 25-#20 Series

Service Rating I II I I I I Contacts 25 26 27 24 25

Shell Size/Layout 22-25 16-26 20-27 18-30 24-31 # of Contacts 25-#16 26-#20 27-#20 1-#16; 29-#20 31-#16 Series

Service Rating I I I I I Contacts 32 34 36 38

Shell Size/Layout 18-32 22-32 22-34 22-36 24-38 # of Contacts 32-#20 32-#20 34-#20 36-#20 38-#16 Series

Service Rating I I I I I Contacts 39 41 51

Shell Size/Layout 20-39 20-41 22-41 24-51 # of Contacts 2-#16 37-#20 41-#20 14-#16; 27-#20 4-#12(coax); 47-#20 Series

Service Rating I I I I Contacts 55 61

Shell Size/Layout 22-55 24-61 # of Contacts 55-#20 61-#20 Series

Service Rating I I Read Less STEP 5: ROTATIONSTEP 5: SELECT ROTATION

See Layout Chart on Step 3 (Omit for normal) Insert Rotations Layout W X Y Z 8-2* 58 122 - - 8-3* 60 210 - - 8-4* 45 97# 184# - 8-33†† 90 - - - 10-6†† 90 - - - 10-98* 90 180 240 270 12-3†† - - 180 - 12-8†† 90 112 203 292 12-10†† 60 155 270 295 14-5†† 40 92 184 273 14-12†† 43 90 - - 14-15†† 17 110 155 234 14-18†† 15 90 180 270 14-19†† 30 165 315 - 14-22* 45 - - - 14-91* - 60 - - 16-8†† 54 152 180 331 16-23†† 158 270 - - 16-26†† 60 - 275 338 16-76* - - - - 16-99†† 66 156 223 340 18-5* 55 97 263 315 18-11†† 62 119 241 340 18-30†† 180 193 285 350 18-32†† 85 138 222 265 18-80 45 90 135 160 18-91* 90 180 240 270 20-16†† 238 318 333 347 20-27* 72 144 216 288 20-39†† 63 144 252 333 20-41†† 45 126 225 - 22-7* 19 41 - - 22-21†† 16 135 175 349 22-25* 60 125 211 336 22-32†† 72 145 215 288 22-34* 62 142 218 298 22-36* 72 144 216 288 22-41†† 39 135 264 - 22-55†† 30 142 226 314 22-78* 19 41 - - 22-96* 19 41 - - 24-31* 90 225 255 - 24-51* 22 171 313 - 24-61†† 90 180 270 324 PART NUMBER KEY: Commercial=(*) Commercial & Military=(††) # = Commercial Rotation Only (Not Military) A = A-Class Only S = Socket Insert Only u = 14-AA Insert Follows 14-4 MIL-STD-1669A contact spacing STEP 6: MODIFIERSTEP 6: SELECT MODIFIER

SR* = F-Style Strain Relief (not military) 002* = Black Anodized 005* = Anodic Coating (Alumilite) 014* = Olive Drab Chromate over Cadmium over Nickel (500-hour salt spray) 023* = Electroless Nickel (RoHS) 024* = Olive Drab Zinc Alloy 025* = Non-Conductive Black Zinc Alloy (RoHS) 027* = Conductive Black Zinc Alloy (RoHS) 072 = Gray Zinc Nickel (RoHS) 424* = Electroless Nickel and Strain Relief (SR & 023) (RoHS) 466* = Olive Drab Zinc Alloy with Strain Relief (SR & 024) 470* = Non-conductive Black Zinc Alloy with Strain Relief (SR & 025) (RoHS) 476* = Conductive Black Zinc Alloy with Strain Relief (SR & 027) (RoHS) SCC* = Self-Closing Cap Box Mount (02) Shell sizes 8,10, 12 & 18 only LC = Less Contacts Commercial=(*) |

|

CRIMP CONTACTSAMPHENOL PT/PT-SE SERIES PIN & SOCKET CRIMP CONTACTS

Pin Crimp Contacts

Wire Strip Length

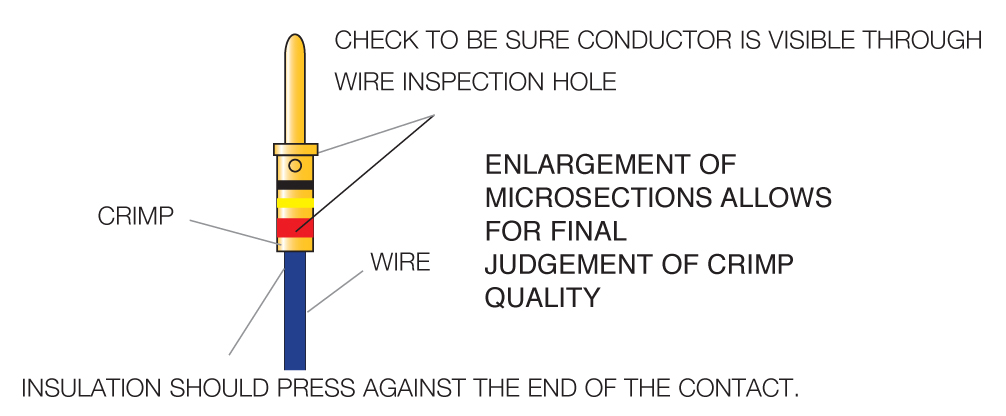

Color Bands Wire Sealing Range Contact Size Wire Size AWG Pin Contact Part Number 1 2 3 Wire Strip Length Min. Max. SE Crimp Contacts 20 20-24 M39029/31-240 Red Yellow Black .275 (7.0) .047 (1.2) .083 (2.1) 16 16-20 M39029/31-228 Red Red Grey .250 (6.4) .066 (1.7) .109 (2.7) 12 12-14 M39029/31-235 Red Orange Green .275 (7.0) .047 (1.2) .083 (2.1) 20 Chromel 20 Alumel 20 Iron 20 Constantan 20-24 20-24 20-24 20-24 10-330940-01P 10-330940-02P 10-330940-03P 10-330940-04P - - - - - - - - - - - - .250 (6.4) .047 (1.2) .083 (2.1) CE Crimp Contacts 20 20-24 10-189000-20F - - - .275 (7.0) .047 (1.2) .083 (2.1) 20 16-20 10-195962-20F - - - .275 (7.0) .047 (1.2) .083 (2.1) 16 16-20 10-189004-16F - - - .250 (6.4) .066 (1.7) .109 (2.7) 20 Chromel 20 Alumel 20 Iron 20 Constantan 20-24 20-24 20-24 20-24 10-252900-01P 10-252900-02P 10-252900-03P 10-252900-04P - - - - - - - - - - - - .275 (7.0) .047 (1.2) .083 (2.1) Socket Crimp Contacts

Wire Strip Length

Color Bands Wire Sealing Range Contact Size Wire Size AWG Socket Contact Part Number 1 2 3 Wire Strip Length Min. Max. SE Crimp Contacts 20 20-24 M39029/32-259 Red Green White .275 (7.0) .047 (1.2) .083 (2.1) 16 16-20 M39029/32-247 Red Yellow Violet .250 (6.4) .066 (1.7) .109 (2.7) 12 12-14 M39029/32-254 Red Green Yellow .275 (7.0) .047 (1.2) .083 (2.1) 20 Chromel 20 Alumel 20 Iron 20 Constantan 20-24 20-24 20-24 20-24 10-330940-01S 10-330940-02S 10-330940-03S 10-330940-04S - - - - - - - - - - - - .250 (6.4) .047 (1.2) .083 (2.1) CE Crimp Contacts 20 20-24 10-597817-351 - - - .275 (7.0) .047 (1.2) .083 (2.1) 20 16-20 10-195963-20F - - - .275 (7.0) .047 (1.2) .083 (2.1) 16 16-20 10-189006-16F - - - .250 (6.4) .066 (1.7) .109 (2.7) 20 Chromel 20 Alumel 20 Iron 20 Constantan 20-24 20-24 20-24 20-24 10-252900-01S 10-252900-02S 10-252900-03S 10-252900-04S - - - - - - - - - - - - .275 (7.0) .047 (1.2) .083 (2.1) All dimensions in inches (millimeters in parentheses) CRIMP TOOLSAMPHENOL PT/PT-SE SERIES PIN & SOCKET CRIMP TOOLS

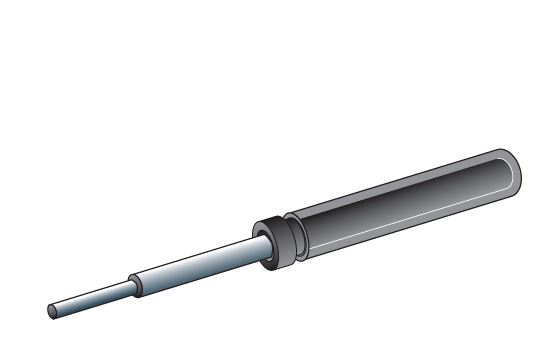

Wire Hole Filler Crimp Tools Insertion Tool Extraction Tool

Contact Size Part Number Color Hand-Crimp Tool Power-Crimp Tool Turret Head Color Use Locator Insertion Tool Extraction Tool SE Crimp Contacts 20 16 12 20 Chromel 20 Alumel 20 Iron 20 Constantan MS27488-20-2 MS27488-16-2 MS27488-12-2

Red Blue Yellow

Red Blue Yellow

M81969/17-03 M81969/17-04 M81969/17-05

M81969/19-07 M81969/19-08 M81969/19-09

CE Crimp Contacts 20 16 12 20 Chromel 20 Alumel 20 Iron 20 Constantan MS27488-20-2 MS27488-20-2 MS27488-16-2

Red Red Blue

Red Red Blue

11-6782 11-6782 11-6781

*Contact us for more tool accessories. CO-AX CONTACTSAMPHENOL PT/PT-SE SERIES PIN & SOCKET SOLDER CO-AX CONTACTS

Contact Part # Outer Shell Crimp Ferrule Cable Pin Socket Fits In Shell Size MIL-C_22520/5-01 Use With Die Part # (Locator Cavity) MIL-C_22520/10-01 Use With Die Part # (Locator Cavity) Clamp Nut Wrench Contact Size 12 RG-161/U RG-174A/U/U RG-179B/U RG-187A/U RG-188A/U RG-316/U

M22520/5-03 (A) M22520/5-08 (A) M22520/5-35 (B)

RG-196A/U 21-033020-031+ 21-033061-031+ 10-18 M22520/5-03 (B) M22520/10-05 (B) 11-8676-1 "Thermatics 2929-29” 21-033020-033 21-033061-033 10-18 M22520/5-37 (B) 11-8676-1 Contact Size 8 RG-58C/U RG-141A/U RG-303/U 21-033020-002 21-033019-002 10-18

M22520/5-41 (B) M22520/10-07 (B) 11-8676-2 RG-59B/U RG-62A/U RG-62B/U RG-210/U 21-033020-003 21-033019-003 10-18 M22520/5-45 (B) - 11-8676-3 RG-142B/U Times MI51115 21-033020-007* 21-033019-007* 10-18 M22520/5-43 (B) - 11-8676-2 RG-178B/U 21-033020-004 21-033019-004 10-18 M22520/5-03 (B) M22520/10-05 (B) 11-8676-2 RG-180B/U RG-195A/U Raychem - 5022D1312-9 21-033020-005* 21-033019-005* 10-18

M22520/5-41 (B) M22520/10-07 (B) 11-8676-2 Raychem - 5021D1331-9 21-033020-006* 21-033019-006* 10-18 M22520/5-05 (B) M22520/10-07 (B) 11-8676-2 RG-59B/U RG-62A/U RG-62B/U RG-210/U 21-033020-001 21-033019-001 20-24 M22520/5-45 (B) - 11-8676-3 Note: Solder contacts are supplied with outer contact body bonded into the insert (insulator). Contact us for wire strip lengths and assembly instructions. * Please check availability + Only mate with one another SOLDER (PT) CRIMP (PT-SE) Pin Socket Pin Socket

Note: Illustrations are chart above. Note: Illustrations are for chart below. AMPHENOL PT/PT-SE SERIES PIN & SOCKET SE CRIMP CO-AX CONTACTS

Inner Solder Contact Pins Sockets Hand-Crimp Tool Cable .00005 Gold Over Silver .00010 Gold Over Copper .00005 Gold Over Silver .00010 Gold Over Copper MIL-C22520/5-01 Use With Die Part # (Locator Cavity) MIL-C22520/10-01 Use With Die Part # (Locator Cavity) Clamp Nut Wrench Insertion Tool Extraction Tool Contact Size 12 RG-161/U

RG-178B/U 21-033012-003* 21-033038-003* 21-033011-003* 21-033037-003* - M22520/10-05 (A) 11-8676-1 11-8369-1 11-7880-12 RG-188 or 21-033012-006* 21-033038-006* 21-033011-006* 21-033037-006* M22520/5-37 (B) - 11-8676-1 11-8369-2 11-7880-12 Westrex

Contact Size 8 RG-55B/U 21-033012-21 21-033038-21 21-033011-21 21-033037-21

M22520/10-07 (A) 11-8676-2 11-8369-5 11-7880-8 RG-58C/U 21-033012-022 21-033038-022* 21-033011-022 21-033037-022

M22520/10-07 (B) 11-8676-2 11-8369-4 11-7880-8 RG-59B/U N/A N/A N/A N/A M22520/5-45 (B)

11-8676-2 11-8369-5 11-7880-8 RG-140/U N/A N/A N/A N/A - M22520/10-07 (A) 11-8676-2 11-8369-5 11-7880-8 RG-161/U

RG-178B/U 21-033012-035 21-033038-035 21-033011-035 21-033037-035

M22520/10-05 (A) 11-8676-2 11-8369-1 11-7880-8 RG-180B/U N/A N/A 21-033011-024 21-033037-024

M22520/10-07 (B) 11-8676-2 11-8369-4 11-7880-8 Thermax N/A N/A N/A N/A M22520/05-37 (B)

11-8676-2 11-8369-5 11-7880-8 RG-195 21-033012-028 21-033038-028* 21-033011-028 21-033037-028* M22520/05-43 (B)

11-8676-2 11-8369-4 11-8660-4 RG-122/U 21-033012-023 21-033038-023* 21-033011-023 21-033037-023*

M22520/10-07 (B) 11-8676-2 11-8369-4 11-7880-8 Tyco 21-033012-031 21-033038-031 21-033011-031 21-033037-031

M22520/10-07 (B) 11-8676-2 11-8369-4 11-7880-8 Tyco N/A N/A N/A N/A

M22520/10-07 (B) 11-8676-2 11-8369-4 11-7880-8 Tyco N/A N/A N/A N/A

M22520/10-05 (A) 11-8676-2 11-8369-2 11-7880-8 Italicized = Matched impedance contacts. *Contact us for availability. Availability of co-ax contacts varies widely. Contact us for strip lengths and assembly instructions. CONNECTOR TOOLSAMPHENOL PT/PT-SE SERIES CONNECTOR TOOLS

TG70 Strap Wrench

TG69P Non-Marring Adjustable Endbell Pliers for Field Service 600 Series Production System The 600 series is a complete system for the proper assembly and torquing of connector endbells. The system includes a bench-mounted or hand-held torque wrench, plug and receptacle holders, and a range of endbell tightening tools. When used together, these tools provide the user with consistent endbell installations. Each item is shipped with detailed assembly instructions.

Rotations Pin Socket W = G W = H X = I X = J Y = K Y = L Z = M Z = N

Plug & Receptacle Holders MIL-DTL-26482 Shell Size For PT, PT-SE, MS311_, MS312_ For PT, PT-SE, MS311_, MS312_ 8 600D005-8R 600D005-8P 10 600D005-10R 600D005-10P 12 600D005-12R 600D005-12P 14 600D005-14R 600D005-14P 16 600D005-16R 600D005-16P 18 600D005-18R 600D005-18P 20 600D005-20R 600D005-20P 22 600D005-22R 600D005-22P 24 600D005-24R 600D005-24P AMPHENOL PT/PT-SE SERIES TORQUE VALUES

IMPORTANT NOTE: If barrel/shell has three threads or less, torque to 30 to 35 inch/Lbs (3.4 to 4.0 NM) per L-725-2. ENDBELL Inch-Lbs. N-M Shell Size Min. Max. Min. Max. 6 20 26 2.3 2.9 8 20 26 2.3 2.9 10 26 32 2.9 3.6 12 30 36 3.4 4.1 14 40 46 4.5 5.2 16 50 55 5.6 6.2 18 60 65 6.8 7.3 20 75 80 8.5 9.0 22 85 90 9.6 10.2 24 100 110 11.3 12.4 JAM NUT Inch-Lbs. N-M Shell Size Min. Max. Min. Max. 8 26 32 2.9 3.6 10 30 36 3.4 4.1 12 46 50 5.2 5.6 14 55 60 6.2 6.8 16 70 75 7.9 8.5 18 80 85 9.0 9.6 20 90 95 10.2 10.7 22 100 110 11.3 12.4 24 110 120 12.4 13.6 |

|

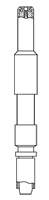

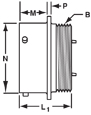

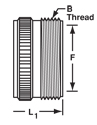

PRINTED CIRCUIT BOARDAMPHENOL PT/PT-SE SERIES PRINTED CIRCUIT BOARD

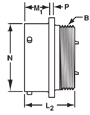

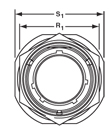

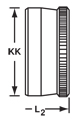

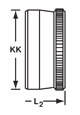

Box Mount Shell Size Part Number PT02 with PCB Contacts M N P R S T L Max. KK Y X 6 71-570120* 0.431 (10.9) 0.348 (8.8) 0.062 (1.6) 0.469 (11.9) 0.688 (17.5) 0.120 (3.0) 0.774 (19.7) 0.323 (8.2) 0.380 (9.7) 0.661 (16.8) 8 71-570121* 0.431 (10.9) 0.473 (12.0) 0.062 (1.6) 0.594 (15.1) 0.812 (20.6) 0.120 (3.0) 0.774 (19.7) 0.449 (11.4) 0.380 (9.7) 0.661 (16.8) 10 71-570122* 0.431 (10.9) 0.590 (15.0) 0.062 (1.6) 0.719 (18.3) 0.938 (23.8) 0.120 (3.0) 0.774 (19.7) 0.573 (14.6) 0.380 (9.7) 0.661 (16.8) 12 71-570123* 0.431 (10.9) 0.750 (19.1) 0.062 (1.6) 0.812 (20.6) 1.031 (26.2) 0.120 (3.0) 0.774 (19.7) 0.699 (17.8) 0.380 (9.7) 0.661 (16.8) 14 71-570124* 0.431 (10.9) 0.875 (22.2) 0.062 (1.6) 0.906 (23.0) 1.125 (28.6) 0.120 (3.0) 0.774 (19.7) 0.823 (20.9) 0.380 (9.7) 0.661 (16.8) 16 71-570125* 0.431 (10.9) 1.000 (25.4) 0.062 (1.6) 0.969 (24.6) 1.219 (31.0) 0.120 (3.0) 0.774 (19.7) 0.949 (24.1) 0.380 (9.7) 0.661 (16.8) 18 71-570126* 0.431 (10.9) 1.125 (28.6) 0.062 (1.6) 1.062 (27.0) 1.312 (33.3) 0.120 (3.0) 0.774 (19.7) 1.073 (27.3) 0.380 (9.7) 0.661 (16.8) 20 71-570127* 0.556 (14.1) 1.250 (31.8) 0.094 (2.4) 1.156 (29.4) 1.438 (36.5) 0.120 (3.0) 1.025 (26.0) 1.199 (30.5) 0.286 (7.3) 0.661 (16.8) 22 71-570128* 0.556 (14.1) 1.375 (34.9) 0.094 (2.4) 1.250 (31.8) 1.561 (39.6) 0.120 (3.0) 1.025 (26.0) 1.323 (33.6) 0.286 (7.3) 0.661 (16.8) 24 71-570129* 0.589 (14.9) 1.500 (38.1) 0.094 (2.4) 1.375 (34.9) 1.688 (42.9) 0.147 (3.7) 1.058 (26.9) 1.449 (36.8) 0.253 (6.4) 0.628 (16.0) Jam Nut Panel Thickness Shell Size Part Number PT07 with PCB Contacts B Thread Class 2A UNEF M1 N P1 R1 S1 Min. Max. L1 Y1 X1 6 71-533720* 0.4375-28 0.696 (17.7) 0.348 (8.8) 0.125 (3.2) 0.625 (15.9) 0.812 (20.6) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 8 71-533721* 0.5625-24 0.696 (17.7) 0.473 (12.0) 0.125 (3.2) 0.750 (19.1) 0.938 (23.8) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 10 71-533722* 0.6875-24 0.696 (17.7) 0.590 (15.0) 0.125 (3.2) 0.875 (22.2) 1.062 (27.0) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 12 71-533723* 0.8750-20 0.696 (17.7) 0.750 (19.1) 0.125 (3.2) 1.062 (27.0) 1.250 (31.8) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 14 71-533724* 1.0000-20 0.696 (17.7) 0.875 (22.2) 0.125 (3.2) 1.188 (30.2) 1.375 (34.9) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 16 71-533725* 1.1250-18 0.696 (17.7) 1.000 (25.4) 0.125 (3.2) 1.312 (33.3) 1.500 (38.1) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 18 71-533726* 1.2500-18 0.696 (17.7) 1.125 (28.6) 0.125 (3.2) 1.438 (36.5) 1.625 (41.3) 0.062 (1.6) 0.125 (3.2) 0.821 (20.9) 0.376 (9.6) 0.501 (12.7) 20 71-533727* 1.3750-18 0.884 (22.5) 1.250 (31.8) 0.156 (4.0) 1.562 (39.7) 1.812 (46.0) 0.062 (1.6) 0.250 (6.4) 1.040 (26.4) 0.367 (9.3) 0.523 (13.3) 22 71-533728* 1.5000-18 0.884 (22.5) 1.375 (34.9) 0.156 (4.0) 1.688 (42.9) 1.938 (49.2) 0.062 (1.6) 0.250 (6.4) 1.040 (26.4) 0.367 (9.3) 0.523 (13.3) 24 71-533729* 1.6250-18 0.917 (23.3) 1.500 (38.1) 0.156 (4.0) 1.812 (46.1) 2.062 (52.4) 0.062 (1.6) 0.250 (6.4) 1.073 (27.2) 0.334 (8.5) 0.490 (12.4) Part number prefix codes: 58 = Conductive Black Alloy (027) RoHS 71 = Olive Drab Chromate over Cadmium (typical) 72 = Anodic Coating (005) 91 = Electroless Nickel (023) RoHS 93 = Non-Conductive Black Alloy (025) RoHS FL = Grey Zinc Nickel (072) RoHS *Click here for insert arrangement (layout) codes. All dimensions in inches (millimeters in parentheses) RECEPTACLESAMPHENOL PT/PT-SE SERIES RECEPTACLE STYLES

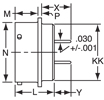

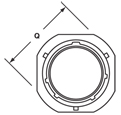

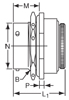

PT00 PT01 PT02 PTB

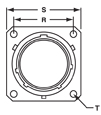

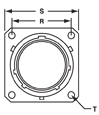

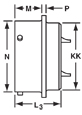

PT00/PT02/PTB PT01 PT00/PT02/PTB PT00 PT02 PTB PT00/PT01 Shell Size M N +.001 -.005 MS31_0 MS31_1 M1 Max. Q R S T L1 Max. L3 Max. KK Dia. Max. L4 Max. L2 Max. B Thread Class 2A 6 0.431 (10.9) 0.348 (8.8) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 0.812 (20.6) 0.469 (11.9) 0.688 (17.5) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 0.323 (8.2) 1.050 (26.7) 0.906 (23.0) .3125-32 NEF 8 0.431 (10.9) 0.473 (12.0) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 0.938 (23.8) 0.594 (15.1) 0.812 (20.6) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 0.449 (11.4) 1.050 (26.7) 0.906 (23.0) .4375-28 UNEF 10 0.431 (10.9) 0.590 (15.0) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 1.062 (27.0) 0.719 (18.3) 0.938 (23.8) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 0.573 (14.6) 1.050 (26.7) 0.906 (23.0) .5625-24 NEF 12 0.431 (10.9) 0.750 (19.1) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 1.156 (29.4) 0.812 (20.6) 1.031 (26.2) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 0.699 (17.8) 1.050 (26.7) 0.906 (23.0) .6875-24 NEF 14 0.431 (10.9) 0.875 (22.2) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 1.250 (31.8) 0.906 (23.0) 1.125 (28.6) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 0.823 (20.9) 1.050 (26.7) 0.906 (23.0) .8125-20 UNEF 16 0.431 (10.9) 1.000 (25.4) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 1.344 (34.1) 0.969 (24.6) 1.219 (31.0) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 0.949 (24.1) 1.050 (26.7) 0.906 (23.0) .9375-20 UNEF 18 0.431 (10.9) 1.125 (28.6) 0.062 (1.6) 0.093 (2.4) 0.400 (10.1) 1.438 (36.5) 1.062 (27.0) 1.312 (33.3) 0.120 (3.0) 0.906 (23.0) 0.825 (21.0) 1.073 (27.3) 1.050 (26.7) 0.906 (23.0) 1.0625-18 NEF 20 0.556 (14.1) 1.250 (31.8) 0.094 (2.4) 0.115 (2.9) 0.535 (13.6) 1.562 (39.7) 1.156 (29.4) 1.438 (36.5) 0.120 (3.0) 1.125 (28.6) 1.076 (27.3) 1.199 (30.5) 1.330 (33.8) 1.125 (28.6) 1.1875-18 NEF 22 0.556 (14.1) 1.375 (34.9) 0.094 (2.4) 0.115 (2.9) 0.535 (13.6) 1.688 (42.9) 1.250 (31.8) 1.562 (39.6) 0.120 (3.0) 1.125 (28.6) 1.076 (27.3) 1.323 (33.6) 1.330 (33.8) 1.125 (28.6) 1.3125-18 NEF 24 0.589 (14.9) 1.500 (38.1) 0.094 (2.4) 0.115 (2.9) 0.568 (14.4) 1.812 (46.0) 1.375 (34.9) 1.688 (42.9) 0.147 (3.7) 1.188 (30.2) 1.109 (28.2) 1.449 (36.8) 1.330 (33.8) 1.188 (30.2) 1.4375-18 NEF AMPHENOL PT/PT-SE SERIES JAM NUT RECEPTACLES

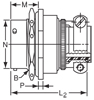

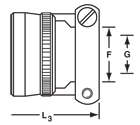

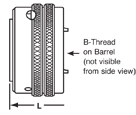

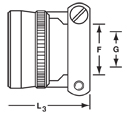

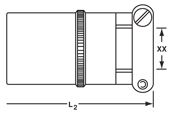

PT07 PT07 Shell Size B Thread UNEF-2A M N P R S Panel Thickness Min. Panel Thickness Max. 6 .4375-28 0.696 0.348 0.125 0.625 0.812 0.062 0.125 8 .5625-24 0.696 0.473 0.125 0.750 0.938 0.062 0.125 10 .6875-24 0.696 0.590 0.125 0.875 1.062 0.062 0.125 12 .8750-20 0.696 0.750 0.125 1.062 1.250 0.062 0.125 14 1.0000-20 0.696 0.875 0.125 1.188 1.375 0.062 0.125 16 1.1250-18 0.696 1.000 0.125 1.312 1.500 0.062 0.125 18 1.2500-18 0.696 1.125 0.125 1.438 1.625 0.062 0.125 20 1.3750-18 0.884 1.250 0.156 1.562 1.812 0.062 0.250 22 1.5000-18 0.884 1.375 0.156 1.688 1.938 0.062 0.250 24 1.6250-18 0.917 1.500 0.156 1.816 2.062 0.062 0.250 PT07A PT07E-SR PT07E- PT07E-SR PT07A PT07E-SR PT07SE-SR PT07P PT07SP Shell Size L L1 Max. L2 Max. L1 Max. L2 Max. F L3 Max. L3 Max. 6 0.821 (20.9) 1.282 (32.6) - - - 0.202 (5.1) 1.289 (32.7) - 8 0.821 (20.9) 1.282 (32.6) 1.758 (44.7) 1.438 (36.5) 1.922 (48.8) 0.327 (8.3) 1.289 (32.7) - 10 0.821 (20.9) 1.282 (32.6) 1.758 (44.7) 1.438 (36.5) 1.922 (48.8) 0.444 (11.3) 1.289 (32.7) 1.656 (42.1) 12 0.821 (20.9) 1.282 (32.6) 1.758 (44.7) 1.438 (36.5) 1.922 (48.8) 0.558 (14.2) 1.289 (32.7) 1.656 (42.1) 14 0.821 (20.9) 1.282 (32.6) 1.758 (44.7) 1.438 (36.5) 1.922 (48.8) 0.683 (17.3) 1.289 (32.7) 1.656 (42.1) 16 0.821 (20.9) 1.282 (32.6) 1.884 (47.9) 1.438 (36.5) 2.000 (50.8) 0.808 (20.5) 1.289 (32.7) 1.656 (42.1) 18 0.821 (20.9) 1.282 (32.6) 1.884 (47.9) 1.438 (36.5) 2.000 (50.8) 0.909 (23.1) 1.289 (32.7) 1.656 (42.1) 20 1.040 (26.4) 1.514 (38.5) 2.134 (54.2) 1.625 (41.4) 2.172 (55.2) 1.034 (26.3) 1.602 (40.7) 1.922 (48.8) 22 1.040 (26.4) 1.514 (38.5) 2.134 (54.2) 1.625 (41.4) 2.172 (55.2) 1.159 (29.4) 1.602 (40.7) 1.922 (48.8) 24 1.073 (27.2) 1.547 (39.3) 2.167 (55.0) 1.688 (48.8) 2.234 (56.7) 1.284 (32.6) 1.635 (41.5) 1.951 (49.6) All dimensions in inches (millimeters in parentheses) ENDBELL STYLESAMPHENOL PT/PT-SE SERIES ENDBELL STYLES

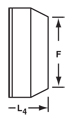

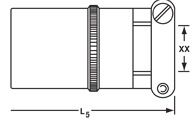

A E F/SR P J W A Endbell E Endbell F/SR Endbell P Endbell W/J Endbell Shell Size F Max. L1 B Thread Class L2 KK Max. F G L3 Max. F L4 Max. XL L5 Max. XX Min. XX Max. 6 0.175 (4.4) 1.553 (39.4) .3750-32 NEF 1.266 (32.2) 0.440 (11.2) - - - 0.192 (4.9) 1.438 (36.5) - - - - 8 0.297 (7.5) 1.553 (39.4) .5000-28 UNEF 1.266 (32.2) 0.560 (14.2) 0.240 (6.1) 0.125 (3.2) 1.922 (48.8) 0.317 (8.1) 1.438 (36.5) 1.705 (43.3) 2.271 (57.7) 0.168 (4.3) 0.230 (5.8) 10 0.421 (10.7) 1.553 (39.4) .6250-24 NEF 1.266 (32.2) 0.685 (17.3) 0.302 (7.7) 0.188 (4.8) 1.922 (48.8) 0.434 (11.0) 1.438 (36.5) 1.705 (43.3) 2.271 (57.7) 0.205 (5.2) 0.312 (7.9) 12 0.546 (13.9) 1.553 (39.4) .7500-20 UNEF 1.266 (32.2) 0.813 (20.7) 0.428 (10.9) 0.312 (7.9) 1.922 (48.8) 0.548 (13.9) 1.438 (36.5) 1.848 (46.9) 2.411 (61.2) 0.338 (8.6) 0.442 (11.2) 14 0.663 (16.8) 1.553 (39.4) .8750-20 UNEF 1.266 (32.2) 0.930 (23.6) 0.552 (14.0) 0.375 (9.5) 1.922 (48.8) 0.673 (17.1) 1.438 (36.5) 2.040 (51.8) 2.599 (66.0) 0.416 (10.6) 0.539 (13.7) 16 0.787 (20.0) 1.553 (39.4) 1.0000-20 UNEF 1.266 (32.2) 1.057 (26.8) 0.615 (15.6) 0.500 (12.7) 2.047 (52.0) 0.798 (20.3) 1.438 (36.5) 2.256 (57.3) 2.943 (74.8) 0.550 (14.0) 0.616 (15.6) 18 0.879 (22.3) 1.553 (39.4) 1.1875-18 NEF 1.266 (32.2) 1.175 (29.8) 0.740 (18.8) 0.625 (15.9) 2.078 (52.8) 0.899 (22.8) 1.438 (36.5) 2.486 (63.1) 3.172 (80.6) 0.600 (15.2) 0.672 (17.1) 20 1.041 (26.4) 1.703 (43.3) 1.1875-18 NEF 1.516 (38.5) 1.301 (33.0) 0.740 (18.8) 0.625 (15.9) 2.344 (59.5) 1.024 (26.0) 1.656 (42.1) 2.922 (74.2) 3.610 (91.7) 0.635 (16.1) 0.747 (19.0) 22 1.135 (28.8) 1.703 (43.3) 1.4375-18 NEF 1.516 (38.5) 1.430 (36.3) 0.928 (23.6) 0.750 (19.1) 2.344 (59.5) 1.149 (29.2) 1.656 (42.1) 3.086 (78.4) 3.766 (95.7) 0.670 (17.0) 0.846 (21.5) 24 1.259 (32.0) 1.765 (44.8) 1.4375-18 NEF 1.578 (40.1) 1.555 (39.5) 0.990 (25.1) 0.800 (20.3) 2.406 (61.1) 1.274 (32.4) 1.717 (43.6) 3.310 (84.1) 3.985 (101.2) 0.740 (18.8) 0.894 (22.7) All dimensions in inches (millimeters in parentheses) PLUGSAMPHENOL PT/PT-SE SERIES STRAIGHT PLUGS

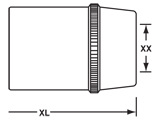

PT06E PT06 PT06A PT06E PTSE06E Shell Size Q L Max. B Thread Class 2A F L1 Max. B Thread Class 2A L2 Max. KK L2 Max. 6 0.625 (15.9) 0.906 (23.0) .3125-32 NEF 0.175 (4.4) 1.553 (39.4) .3750-32 NEF 1.266 (32.2) 0.440 (11.2) - 8 0.750 (19.1) 0.906 (23.0) .4375-28 UNEF 0.297 (7.5) 1.553 (39.4) .5000-28 UNEF 1.266 (32.2) 0.560 (14.2) 1.328 (33.7) 10 0.859 (21.8) 0.906 (23.0) .5625-24 NEF 0.421 (10.7) 1.553 (39.4) .6250-24 NEF 1.266 (32.2) 0.685 (17.3) 1.328 (33.7) 12 1.013 (25.7) 0.906 (23.0) .6875-24 NEF 0.546 (13.9) 1.553 (39.4) .7500-20 UNEF 1.266 (32.2) 0.813 (20.7) 1.328 (33.7) 14 1.156 (29.4) 0.906 (23.0) .8125-20 UNEF 0.663 (16.8) 1.553 (39.4) .8750-20 UNEF 1.266 (32.2) 0.930 (23.6) 1.328 (33.7) 16 1.281 (32.5) 0.906 (23.0) .9375-20 UNEF 0.787 (20.0) 1.553 (39.4) 1.0000-20 UNEF 1.266 (32.2) 1.057 (26.8) 1.328 (33.7) 18 1.319 (33.5) 0.906 (23.0) 1.0625-18 NEF 0.879 (22.3) 1.553 (39.4) 1.1875-18 NEF 1.266 (32.2) 1.175 (29.8) 1.328 (33.7) 20 1.531 (38.9) 1.062 (27.0) 1.1875-18 NEF 1.014 (25.8) 1.703 (43.3) 1.1875-18 NEF 1.438 (36.5) 1.301 (33.0) 1.297 (32.9) 22 1.656 (42.1) 1.062 (27.0) 1.3125-18 NEF 1.135 (28.8) 1.703 (43.3) 1.4375-18 NEF 1.438 (36.5) 1.430 (36.3) 1.297 (32.9) 24* 1.776 (45.1) 1.125 (28.6) 1.4375-18 NEF 1.259 (32.0) 1.765 (44.8) 1.4375-18 NEF 1.500 (38.1) 1.555 (39.5) 1.359 (34.5) PT06E-SR PT06P

PT06E/SR PTSE06/SR PT06P PT06W/SR PT06J/SR PT06W/J Shell Size F G L3 Max. L3 Max. F Dia. L1 Max. XL L2 Max. XX Min. XX Max. 6 - - - - 0.192 (4.9) 1.526 (38.8) - - - - 8 0.240 (6.1) 0.125 (3.2) 1.906 (48.4) 2.413 (61.3) 0.317 (8.1) 1.526 (38.8) 1.705 (43.3) 2.271 (57.7) 0.168 (4.3) 0.230 (5.8) 10 0.302 (7.7) 0.188 (4.8) 1.906 (48.4) 2.413 (61.3) 0.434 (11.0) 1.526 (38.8) 1.705 (43.3) 2.271 (57.7) 0.205 (5.2) 0.312 (7.9) 12 0.428 (10.9) 0.312 (7.9) 1.906 (48.4) 2.413 (61.3) 0.548 (13.9) 1.526 (38.8) 1.848 (46.9) 2.411 (61.2) 0.338 (8.6) 0.442 (11.2) 14 0.552 (14.0) 0.375 (9.5) 1.906 (48.4) 2.413 (61.3) 0.673 (17.1) 1.526 (38.8) 2.040 (51.8) 2.599 (66.0) 0.416 (10.6) 0.539 (13.7) 16 0.615 (15.6) 0.500 (12.7) 2.047 (52.0) 2.528 (64.2) 0.798 (20.3) 1.526 (38.8) 2.256 (57.3) 2.943 (74.8) 0.550 (14.0) 0.616 (15.6) 18 0.740 (18.8) 0.625 (15.9) 2.078 (52.8) 2.528 (64.2) 0.899 (22.8) 1.526 (38.8) 2.486 (63.1) 3.172 (80.6) 0.600 (15.2) 0.672 (17.1) 20 0.740 (18.8) 0.625 (15.9) 2.250 (57.2) 2.753 (70.0) 1.024 (26.0) 1.546 (39.3) 2.844 (72.2) 3.610 (91.7) 0.635 (16.1) 0.747 (19.0) 22 0.928 (23.6) 0.750 (19.1) 2.250 (57.2) 2.753 (70.0) 1.149 (29.2) 1.546 (39.3) 3.000 (76.2) 3.766 (95.7) 0.670 (17.0) 0.846 (21.5) 24* 0.990 (25.1) 0.800 (20.3) 2.312 (58.7) 2.830 (71.9) 1.274 (32.4) 1.656 (42.1) 3.210 (81.5) 3.985 (101.2) 0.740 (18.8) 0.894 (22.7) AMPHENOL PT/PT-SE SERIES RIGHT ANGLE PLUGS

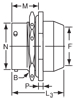

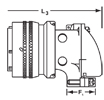

PT08E

PT08P

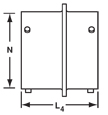

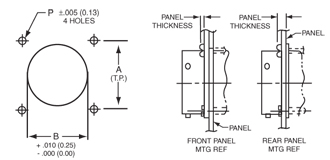

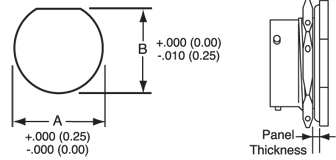

PT08E PTSE08E PT08P PTSE08P Shell Size Q F1 L3 Max. L3 Max. F2 L4 Max. L4 Max. 6 - - - - - - - 8 0.796 (20.2) 0.169 (4.3) 1.786 (45.4) - 0.312 (7.9) 1.656 (42.1) - 10 0.921 (23.4) 0.170 (4.3) 1.880 (47.8) 2.137 (54.3) 0.438 (11.1) 1.781 (45.2) 2.031 (51.6) 12 1.046 (26.6) 0.264 (6.7) 1.965 (49.9) 2.222 (56.4) 0.516 (13.1) 1.743 (44.3) 2.093 (53.2) 14 1.171 (29.7) 0.310 (7.9) 2.113 (53.7) 2.370 (60.2) 0.625 (15.9) 1.953 (49.6) 2.203 (56.0) 16 1.297 (32.9) 0.330 (8.4) 2.315 (58.8) 2.572 (65.3) 0.656 (16.7) 2.000 (50.8) 2.250 (57.2) 18 1.422 (36.1) 0.444 (11.3) 2.423 (61.5) 2.680 (68.1) 0.703 (17.9) 2.046 (52.0) 2.296 (58.3) 20 1.562 (39.7) 0.510 (13.0) 2.695 (68.5) 2.753 (68.9) 0.766 (19.5) 2.218 (56.3) 2.343 (59.5) 22 1.672 (42.5) 0.515 (13.1) 2.742 (69.6) 2.799 (71.1) 0.812 (20.6) 2.265 (57.5) 2.390 (60.7) 24 1.797 (45.6) 0.656 (16.7) 2.980 (75.7) 3.037 (77.1) 0.918 (23.3) 2.624 (66.6) 2.624 (66.6) All dimensions in inches (millimeters in parentheses) PANEL CUTOUT/THICKNESSAMPHENOL PT/PT-SE SERIES PT00/PT02/PTB

Panel Thickness Shell Size B Front Mount A P ±.005 (±.125) Screw Size B PT00/PT02 B PTB 6 0.492 (12.5) 0.469 (11.9) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 8 0.618 (15.7) 0.594 (15.1) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 10 0.735 (18.7) 0.719 (18.3) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 12 0.859 (21.8) 0.812 (20.6) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 14 0.985 (25) 0.906 (23.0) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 16 1.113 (28.3) 0.969 (24.6) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 18 1.235 (31.4) 1.062 (27.0) 0.125 (3.2) #4 0.087 (2.2) 0.218 (5.5) 20 1.361 (34.6) 1.156 (29.4) 0.125 (3.2) #4 0.212 (5.4) 0.344 (8.7) 22 1.485 (37.7) 1.250 (31.8) 0.125 (3.2) #4 0.212 (5.4) 0.344 (8.7) 24 1.611 (40.9) 1.375 (34.9) 0.155 (3.9) #6 0.212 (5.4) 0.311 (7.9) AMPHENOL PT/PT-SE SERIES PT07

Panel Thickness Shell Size A +010-.000 (+.25-.00) B +.000-.010 (+.00-.25) Min. Max. 6 0.447 (11.4) 0.420 (10.7) 0.062 (1.6) 0.125 (3.2) 8 0.572 (14.5) 0.542 (13.8) 0.062 (1.6) 0.125 (3.2) 10 0.697 (17.7) 0.669 (17.0) 0.062 (1.6) 0.125 (3.2) 12 0.884 (22.5) 0.830 (21.1) 0.062 (1.6) 0.125 (3.2) 14 1.007 (25.6) 0.955 (24.3) 0.062 (1.6) 0.125 (3.2) 16 1.134 (28.8) 1.084 (27.5) 0.062 (1.6) 0.125 (3.2) 18 1.259 (32.0) 1.208 (30.7) 0.062 (1.6) 0.125 (3.2) 20 1.384 (35.2) 1.333 (33.9) 0.062 (1.6) 0.250 (6.4) 22 1.507 (38.3) 1.459 (37.1) 0.062 (1.6) 0.250 (6.4) 24 1.634 (41.5) 1.575 (40.0) 0.062 (1.6) 0.250 (6.4) All dimensions in inches (millimeters in parentheses) |

|

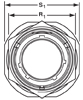

AMPHENOL PT/PT-SE SERIES MS3057-C WATERPROOF CABLE CLAMP

Flange Mount Receptacle Accessories Gasket Nut Plate Sealing Screws Dummy Receptacle Dust Caps Plug Dust Cap Receptacle Flange Dust Cap Receptacle Jam Nut Dust Cap Cable Clamp Flange Mount Receptacle Accessories Dust Caps Shell Size Gasket Nut Plate Sealing Screws Dummy Receptacle Plugs Receptacles Receptacles Cable Clamp for A Endbells 8 10-101949-008 M85049/95-8A S440-1/2 MS3115-8 MS3180-8C* MS3181-8C* MS3181-8N* MS3057-3A 10 10-101949-010 M85049/95-10A S440-1/2 MS3115-10 MS3180-10C* MS3181-10C* MS3181-10N* MS3057-4A 12 10-101949-012 M85049/95-12A S440-1/2 MS3115-12 MS3180-12C* MS3181-12C* MS3181-12N* MS3057-6A 14 10-101949-014 M85049/95-14A S440-1/2 MS3115-14 MS3180-14C* MS3181-14C* MS3181-14N* MS3057-8A 16 10-101949-016 M85049/95-16A S440-1/2 MS3115-16 MS3180-16C* MS3181-16C* MS3181-16N* MS3057-10A 18 10-101949-018 M85049/95-18A S440-1/2 MS3115-18 MS3180-18C* MS3181-18C* MS3181-18N* MS3057-12A 20 10-101949-020 M85049/95-20A S440-1/2 MS3115-20 MS3180-20C* MS3181-20C* MS3181-20N* MS3057-12A 22 10-101949-022 M85049/95-22A S440-1/2 MS3115-22 MS3180-22C* MS3181-22C* MS3181-22N* MS3057-16A 24 10-101949-024 M85049/95-24B S632-1/2 MS3115-24 MS3180-24C* MS3181-24C* MS3181-24N* MS3057-16A *A = Anodized plating (omit A for olive drab) All dimensions in inches (millimeters in parenthesis) |

|

SOLDER CONTACTSAMPHENOL PT/PT-SE SERIES PT SOLDER CONTACTS

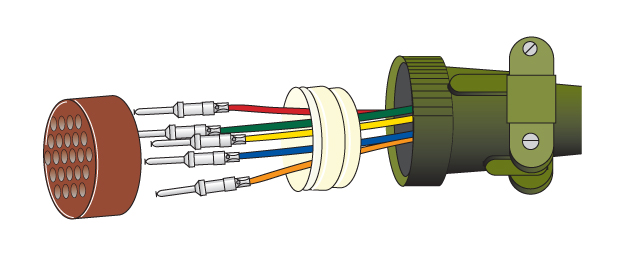

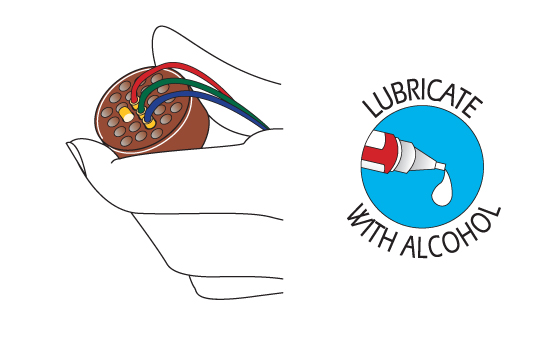

STEP 1: Slide the rear accessories over the wire bundle in the proper sequence for re-assembly: cable clamp and/ or endbell first, then ferrule and, if used, coupling nut. STEP 2: Insert individual wires through the proper holes in the grommet. Use isopropyl alcohol as a lubricant. STEP 3: Solder wires to appropriate contacts on the rear of the connector. Information on standard soldering practices is available upon request. Please contact us. STEP 4: Fixture the connector for reassembly using the endbell assembly tools or a mating connector with contacts installed. STEP 5: Slide the grommet down the wires (lubricating the grommet with isopropyl alcohol will help). STEP 6: Fill all unused grommet cavities with a wire hole filler to maintain the sealing integrity of the connector. STEP 7: Slide coupling nut, ferrule, and endbell accessories over rear of the connector and tighten. Click here for more information. CRIMP TOOL OPERATIONAMPHENOL PT/PT-SE SERIES PTSE & PTCE CRIMP TOOL OPERATION

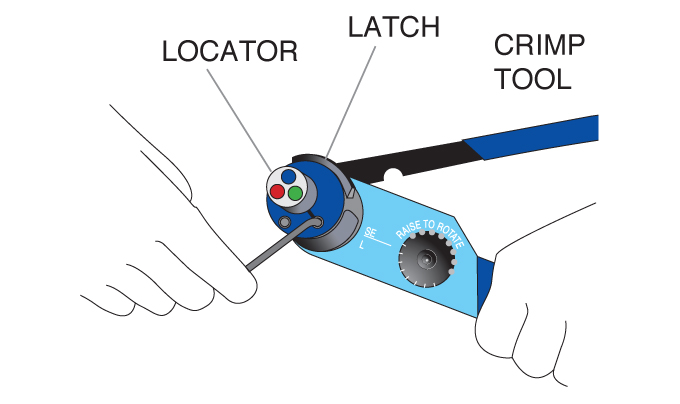

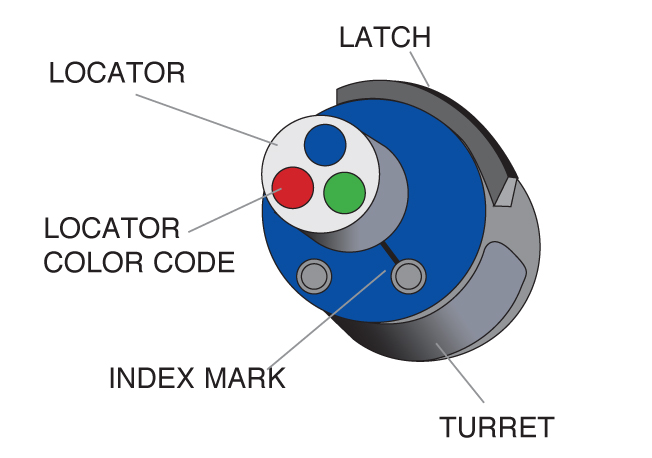

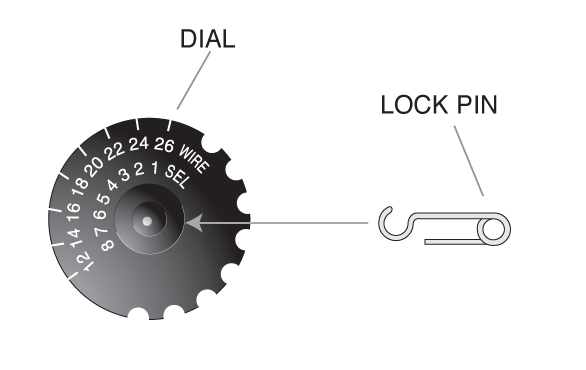

STEP 1: Strip the wires to the appropriate length. Contact Size Strip Length 20 .275 (7.0) 16 .250 (6.4) 12 .250 (6.4) STEP 2: Open the AF8 (M22520/1-01) crimp tool by squeezing the handles. Push the latch on TH1A (M22520/1-02) to pop up the locator on the turret. Attach the turret to the AF8 crimp tool using the two captive hex bolts in the turret. STEP 3: Select the proper locator position for your contact by rotating the locator until the proper color is aligned with the index mark. Push locator back down until it snaps into position. Contact Size Locator Color 20 Red 16 Blue 12 Yellow

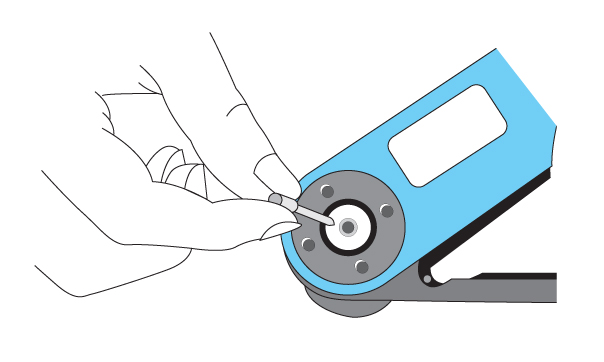

STEP 4: Adjust dial for proper wire gauge. To change the dial setting, remove the lock pin and lift center of dial. Turn to the desired wire gauge. Replace lock pin on dial. STEP 5: Cycle the tool before inserting the contact to be sure the tool is in the open position. Drop the contact, mating end first, into the crimp cavity of the tool. Squeeze the tool handle just enough to grip the contact without actually crimping it. STEP 6: Insert the stripped wire into the contact with a slight twisting motion. Be sure all wire strands are inside the contact. Squeeze the handle to cycle the tool. The handle will not release until the contact is completely crimped.

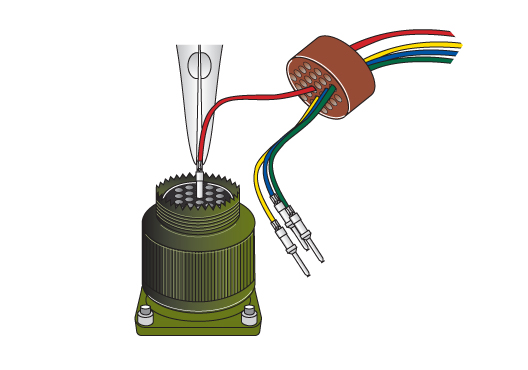

STEP 7: Remove the crimped contact. Pull on the wire slightly to be sure it is properly crimped. Be sure the contact is not bent or damaged in any way. Visually inspect the crimp. CONTACT INSERTIONAMPHENOL PT/PT-SE SERIES CONTACT INSERTION

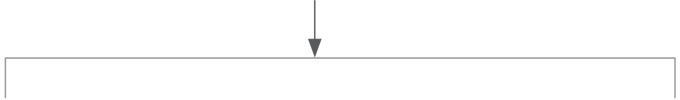

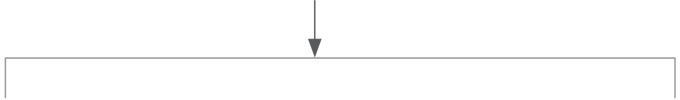

STEP 1: Slide the rear accessories over the wire bundle in the proper sequence for re-assembly: cable clamp and/or endbell first, then ferrule, and coupling nut. STEP 2: Using the proper insertion tool from the Contact Selection Chart, slide the tool over the wire side of the contact until the tool bottoms on the contact. The tool for size 16 contacts presses against the shoulder of the contact. The rear, or insulation support, of the size 20 contacts presses against an internal shoulder in the tool tip. STEP 3: Dip the contact and tool tip in isopropyl alcohol (do not use any lubricant other than isopropyl alcohol). Hold the tool perpendicular to the rear of the connector. Beginning with the center cavity and working outwards in a circular pattern, insert the wired contact into the rear of the connector until the contact snaps into place. A light pull on the wire will ensure that the contact is locked securely.   STEP 4: Fill any unused cavities with contacts. A wire hole filler must be inserted into the grommet behind the unused contacts to maintain the sealing integrity of the connector. STEP 5: Check the mating face of the connector to ensure that all the same size contacts are on the same plane (fully inserted). If not, the contact is not fully inserted. Remove the contact using the proper extraction tool and procedure and re-insert. Do not attempt to reinsert the insertion tool to correct the problem. STEP 6: Fixture the connector for re-assembly using endbell assembly tools or a mating connector with contacts installed. Slide the connector accessories back down the cable over the rear of the connector and tighten. Torque as shown. CONTACT EXTRACTIONAMPHENOL PT/PT-SE SERIES CONTACT EXTRACTION

STEP 1: Remove the endbell accessories and slide them back over the wires. STEP 2: Use the proper extraction tool from the Pin & Socket Crimp Contact chart. STEP 3: On the mating face of the connector, insert the tool over the contact and into the insulator until the tool bottoms. While keeping an even pressure against the tool, push the plunger on the tool shaft forward with your thumb and index finger. This will release the contact from the retention tine and push it toward the rear of the connector. STEP 4: Carefully remove the extraction tool from the connector. Pull the wire by hand to completely remove the contact from the rear of the connector. |

Philadelphia

19116

Click here for the contact information of the branch nearest you.

= 20

= 20 = 16

= 16 = HV

= HV = 20

= 20 = coax

= coax = PT-Solder

= PT-Solder = PT-SE Crimp

= PT-SE Crimp = Solder: Military & PT

= Solder: Military & PT = Crimp: Military & PT-SE

= Crimp: Military & PT-SE = PT-CE

= PT-CE