ITT Cannon CLC Series Clip Lock Circular Vector Connectors

SEALED CLIP LOCK CIRCULAR CONNECTORS

ITT Cannon CLC series clip lock circular vector connectors utilize a 1mm contact system for the smallest sensor connector with dependable integrity. The CLC series is an environmentally-resistant, harsh environment connector designed for under-the-hood automotive and off-road vehicle applications where a small-size, positive-locking, sealed connection is required, for instance in sensors, valves, automotive harnesses, marine, off-road vehicles and CAN buss applications.

ITT Cannon clip lock circular connectors are user-friendly and easy to install and service, with audible and tactile feedback. The CLC series is available as a 2 pin connector and a 4 pin connector.

For full product details on the ITT Cannon CLC series clip lock circular connectors, see the specifications below.

|

ITT CANNON CLC SERIES FEATURES

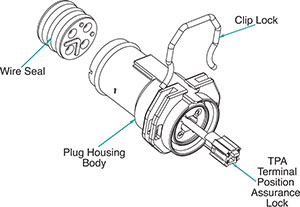

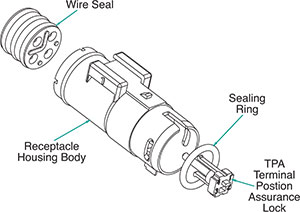

- Clip Lock

Mating connectors are securely locked together by a stainless steel clip. Connector halves simply slide together until the clip snaps into place. To unmate the connectors, just depress the clip and slide the connectors apart.

- Extremely Small Size

CLC series connectors are one of the smallest connector packages available, able to be installed in tight places where larger, bulkier connectors cannot be used.

- Terminal Position Assurance (TPA) (Optional)

The TPA system was designed with the automotive market in mind. Crimped-on contacts are inserted and extracted from the rear of the connector by hand without having to use insertion or extraction tools. Just insert the contact into the connector body until it snaps into place, then depress the bright orange TPA lock and your contacts are locked into place and cannot be removed until the TPA lock is lifted. This allows the contact to be eased out the rear of the connector for repair or replacement. Please note that the TPA lock will not permit a contact to be partially inserted.

- Strong Resistance to Environmental Contaminants

High performance thermoplastic bodies, silicone wire seals, and stainless steel clips withstand the rigors of under-the-hood contaminants including oils, fuels, greases, and salt spray.

- Cost-Effective Design

Several factors make this connector very cost efficient, including high volume reeled contacts for use with stripper crimper machines, low per unit cost, no special insertion/extraction tools needed and their ability to be robotically assembled.

ITT CANNON CLC SERIES MATERIALS & FINISHES

Connector Housing High-performance thermoplastic body, silicone wire seals with stainless steel locking clip

Platings Selective gold over nickel plating on mating surface, tin/lead over nickel plating on wire crimp area

ITT CANNON CLC SERIES ELECTRICAL DATA

Dielectric Withstanding Voltage 1000 Vac rms at sea level

Current Rating 5 Amps continuous at 150°C

Wire Range Sizes 20 - 16 AWG

Contact Resistance 10 milliohms maximum

Insulation Resistance 20 megohms minimum (USCAR)

ITT CANNON CLC SERIES MECHANICAL

Operating Temperature -40°C to 150°C (-40°F to 302°F)

Sealing 2 - 12 inches of 5% salt solution for 24 hours

Wire Sealing Range .078” - .130” (1.98mm - 3.30mm)

Insulation Strip Length .210” - .220” (5.33mm - 5.59mm)

Mating Life 25 cycles minimum

Salt Spray 5% solution 96 hours

Heat 150°C +/- 3° 1000 hours

Chemical Resistance Resistant to most common automotive contaminants

Vibration 10.2 grms 20 hours radial and longitudinal axis

Shock 100 g’s 12 shocks for 6 milliseconds

Contact Type Crimp using automatic, semi-automatic or hand tooling

Contact Insertion From rear, no insertion tool needed

Contact Retention 25 lbs. (111N) minimum

Polarization Molded key and keyway

|

|

ITT CANNON CLC SERIES APPLICATIONS

- Sensors

- Automotive harnesses

- Off highway vehicles

- Marine

- Valves

- Transmission sensors

- Under-hood (bonnet) equipment

- Control area networks (CAN Buss)

|

|

ITT CANNON CLC SERIES SELECT PART NUMBER

2

086-0058-000

086-0066-000

w/ TPA

4

086-0068-000

w/TPA 086-0068-002

w/TPA & 120** Resistor

TPA = Terminal Position Assurance

030-2464-007

110238-0446

030-2480-000

030-2480-007

Hooded 110238-0488

110238-1016 Hooded 112108-0007

Automatic/Semi-

Automatic Please Contact Us

.210 - .220 IN

(5.33 - 5.99 mm)

.095 - .130 IN

(2.42 - 3.30 mm) 225-0093-000

274-7068-001

323-9519-000

Replacement Tip

ITT CANNON CLC SERIES EXPLODED VIEW

|

|

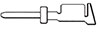

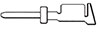

ITT CANNON CLC SERIES CONTACTS & TOOLING

030-2464-007

110238-0446

030-2480-000

030-2480-007

Hooded 110238-0488

110238-1016 Hooded 112108-0007

Automatic/Semi-

Automatic Please Contact Us

.210 - .220 IN

(5.33 - 5.99 mm)

.095 - .130 IN

(2.42 - 3.30 mm) 225-0093-000

274-7068-001

323-9519-000

Replacement Tip

|

|

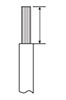

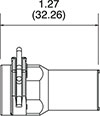

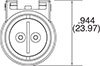

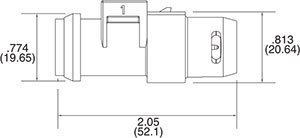

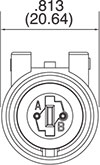

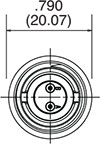

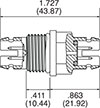

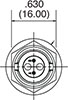

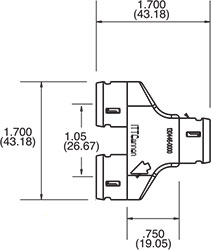

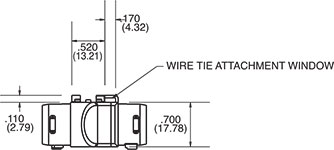

ITT CANNON CLC SERIES CLC 2 PLUG

ITT CANNON CLC SERIES CLC 2 INLINE RECEPTACLE

ITT CANNON CLC SERIES CLC 2 FEED-THROUGH RECEPTACLE

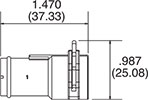

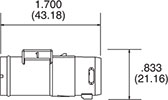

ITT CANNON CLC SERIES CLC 4 PLUG

ITT CANNON CLC SERIES CLC 4 INLINE RECEPTACLE

ITT CANNON CLC SERIES CLC 4Y-SPLICE

|

|

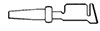

ITT CANNON CLC SERIES CRIMPING INSTRUCTIONS

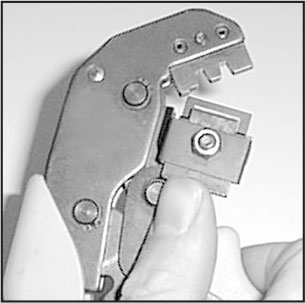

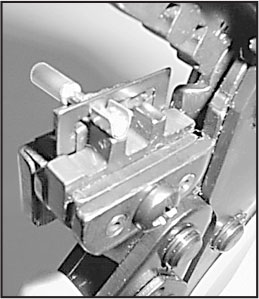

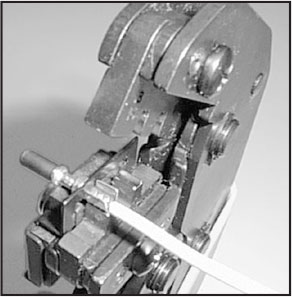

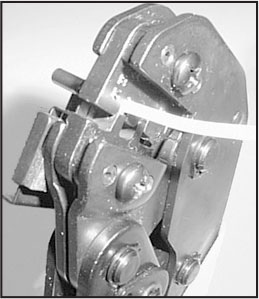

STEP 1: Squeeze handles until tool has gone through a complete cycle and opens easily.

STEP 2: Select the proper cavity for the wire size to be crimped.

STEP 3: Using your thumb or forefinger, raise the spring-loaded locator on the back of the lower jaw by pushing up.

STEP 4: While the locator is in the up position, place the contact into the front of the crimp tool (crimp side up) in the proper crimp cavity (16 AWG or 20 AWG).

STEP 5: Release the locator. The locator should rest comfortably in the indent in the contact just above the crimp

area. STEP 6: Insert the stripped wire into the crimp area until it bottoms.

STEP 7: Firmly squeeze the handle, crimp jaw, ratchet will release.

STEP 8: Using your thumb or forefinger, raise the spring-loaded locator and remove the crimped contact and wire.

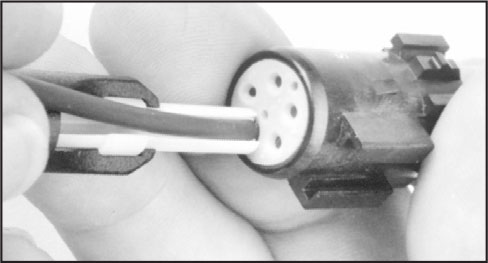

ITT CANNON CLC SERIES INSERTION INSTRUCTIONS

STEP 1: Move to the rear of the connector so that the contact cavities can be identified.

STEP 2: Insert a crimp-terminated assembly into a selected cavity.

STEP 3: Continue the forward movement until an audible snap can be felt and heard. A slight pull in the opposite direction will confirm complete insertion.

STEP 4 - For TPA version: Depress orange TPA lock and verify terminal location. Note: The TPA lock will not permit a contact to be partially inserted. If the contact had been pushed back when the TPA was depressed, simply pull the TPA tab forward, reinsert the contact and depress the TPA again to lock in the contact.

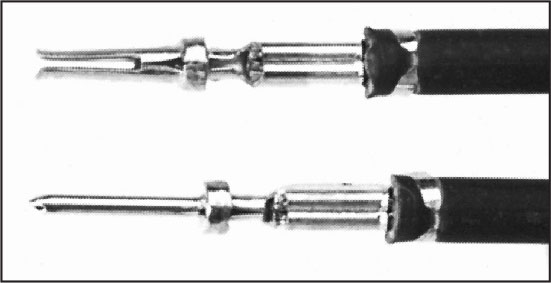

ITT CANNON CLC SERIES CRIMP INSPECTION

Note that there are no unterminated wire strands and that some strand ends can be seen at the forward edge of the crimp. Also note the insulation is gripped by the smaller, secondary crimp. Distortion is at a minimum both axially and laterally – no sharp edges. Enlargement of micro section allows for final judgment of crimp quality. This test is recommended whenever new tools or new types of wire are used.

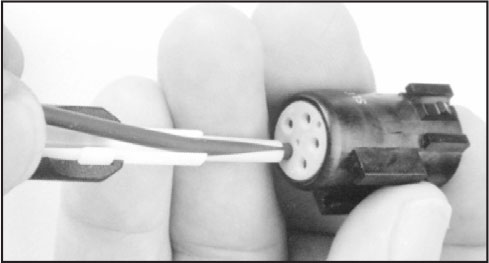

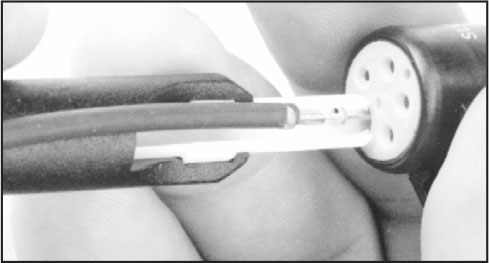

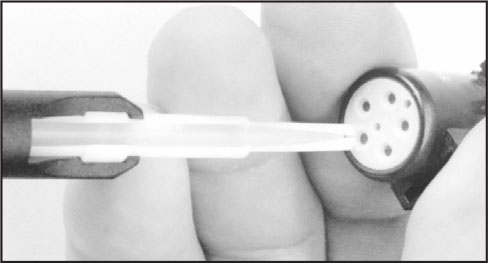

ITT CANNON CLC SERIES EXTRACTION WITHOUT TPA

STEP 1: Open the CET – SLC extraction tool and place it over the insulation of the wire.

STEP 2: Using a straight forward motion, insert the tool along the wire until it bottoms against the connector. (Do not use a screwing motion - damage will result.) STEP 3: While the CET - SLC is bottomed, simply pull the wire/contact assembly out.

STEP 4: Remove the CET - SLC. Extraction is complete.

NOTE: SLC Shown

For TPA Contact Extraction, lift orange TPA lock and gently remove contact from rear. No extraction tool is required.

|