ITT Cannon KP Series Connectors

HIGH DENSITY MINIATURE CIRCULAR INTERCONNECTS FOR THE HARSHEST ENVIRONMENTS

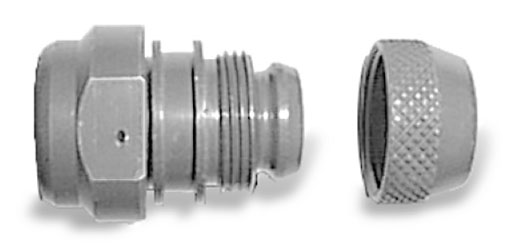

ITT Cannon KPT / KPSE / KPTC connectors offer high-density contact arrangements in a miniature circular connector. Available in 10 shells sizes, with 40 layouts ranging from 2 to 61 contacts; the KP family feature a secure 3-point locking system and five-way polarization for precise alignment. The KPT series (thru-bulkhead) offers a range of solder cup contacts while the KPSE connector offers crimp contacts. Both series are engineered to be comparable to MIL-DTL-26482 and are intermatable with VG95328 connectors and 26482-Style Series I connectors.

The ITT Cannon KPT / KPSE connector series also offers a comprehensive range of back shells, accessories and plating options making it and ideal solution in harsh environment applications. For full details on ITT Cannon KPT / KPSE connector series, please see the product specifications below.

|

FEATURESITT CANNON KPT SERIES FEATURES

MATERIALS & FINISHESITT CANNON KPT SERIES MATERIALS & FINISHES

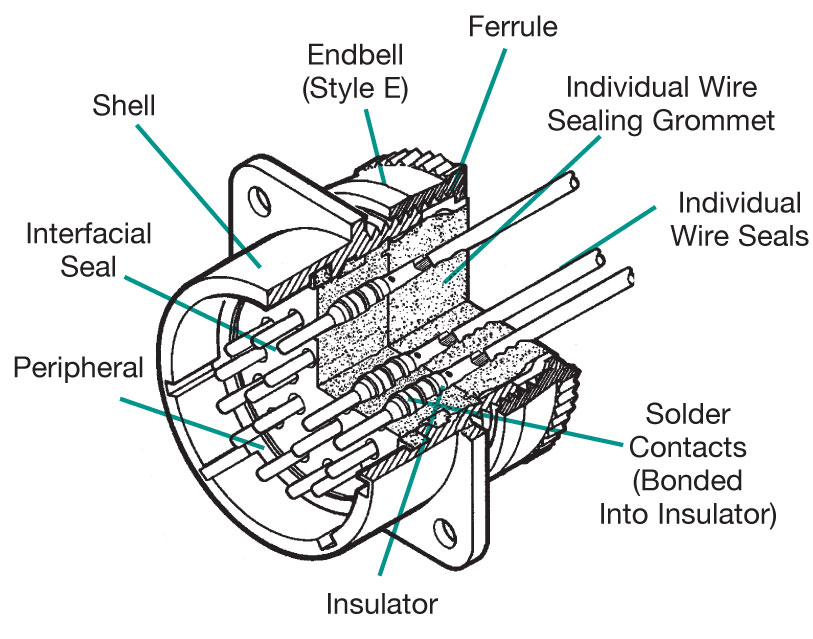

Shell Aluminum alloy

Plating Olive drab chromate coating over cadmium plating, black zinc cobalt or electroless nickel

Contacts Copper alloy

Platings Gold plate, 50 microinches minimum per MIL-G-45204 Type II

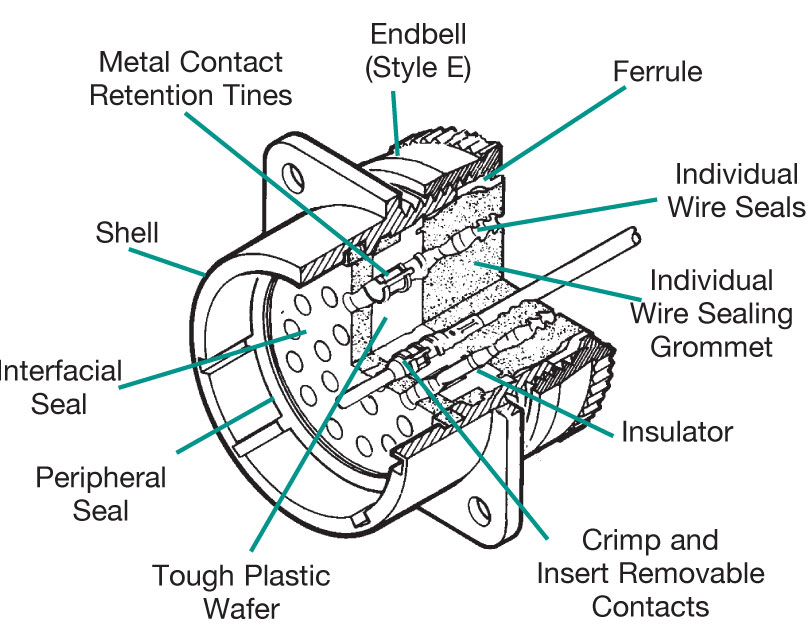

Insulator Resilient polychloroprene (Neoprene). KPSE insulators also encase a tough plastic wafer which contains metal contact retention tines for high reliability retention of crimp contacts.

Optional zero halogen and high temperature insulators are available. Contact us for information. ELECTRICAL DATAITT CANNON KPT SERIES ELECTRICAL DATA

Operating Voltage & Test Voltage Service Rating Test Altitude Maximum Operating Voltage DC Maximum Operating Voltage AC (RMS) Test Voltage DC Test Voltage AC (RMS) I II Sea Level 850 1,275 600 1,000 2,100 3,200 1,500 2,300 I II 70,000 feet - - 300 450 535 770 375 500 *Each insulator has a specific "Service Rating." The Service Ratings for each layout are listed here. Current Rating Contact Size Rated Current Amps Test Current Amps Potential Drop (Millivolts) Initial 20 7.5 7.5 < 55 16 22 13 < 50 Wire Range Sizes 24 to 16 AWG

Contact Resistance When tested to MIL-STD-1344 Method 3004, will not exceed voltage drops listed in table. Consult MIL-DTL-26482, 3.6.4 for details.

Insulation Resistance 5,000 Megohms minimum at 77˚F (25˚C)

MECHANICALITT CANNON KPT SERIES MECHANICAL

Operating Temperature -67˚F to +257˚F (-55˚C to +125˚C)

Sealing 48 hours in 6 feet of water per MIL-DTL-26482 4.6.14. Meets 10- and 20-day 50 to 95% humidity testing per MIL-STD-1344 Method 1002.2 per MIL-DTL-26482; Solder Only.

Crimp: should have contacts installed in all positions when the connector is wired. Sealing plugs should be installed in the grommet holes when no wire is attached to the contact. Wire Sealing Range Contact Size AWG Wire Size Min. (KPT) Min. (KPSE) Max. (KPT/KPSE) 20 24, 22, and 20 .060 (1.52) .047 (1.19) .083 (2.77) 16 20, 18, and 16 .066 (1.68) .066 (1.68) .109 (2.77) Insulation Strip Lengths Contact Size Wire Size (AWG) Strip Length Inches (mm) 20 20-24 .375 (9.5) 16 16-20 .250 (6.35) Mating Life 500 cycles minimum

Salt Spray Unmated connectors and protective covers meet 48-hour exposure to MIL-STD-1344 Method 1001 per MIL-DTL-26482. (Cadmium Plating)

Heat +347˚F (+175˚C) for 1,000 hours to MIL-STD-1344 Method 1005.1 per MIL-DTL-26482

Chemical Resistance 20 hour full immersion unmated in hydraulic fluid and lubricating oil per MIL-DTL-26482

Vibration 10 to 2,000Hz (15g’s) 10 microseconds maximum discontinuity.

To MIL-STD-1344 Method 2005 per MIL-DTL-26482. Shock 50g’s, 11ms duration, three major axes. 10 microseconds maximum discontinuity.

To MIL-STD-1344 Method 2004 per MIL-DTL-26482. Contact Type Solder, crimp, printed circuit, thermocouple

Number of Circuits KPT: 2 to 61; KPSE: 3 to 61

Contact Insertion (crimp) Insertion from the rear of connector with simple hand tool. Front release with appropriate extraction tool.

Contact Retention To MIL-STD-1344 Method 2007 per MIL-DTL-26482.

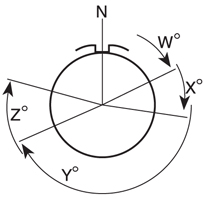

Contact Size Axial Load Min. Newtons (Lbs) 20 66.7 (15) 16 111.2 (25) Polarization Five keyway, three-point bayonet with optional rotational polarization.

Approvals VG95328

|

|

ITT CANNON KPT SERIES APPLICATIONS

Military and Industrial environments requiring a miniature, high-density, environmental connector.

|

|

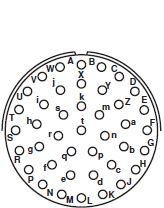

STEP 1: STYLEITT CANNON KPT SERIES COMMERCIAL EXAMPLE

1 2 3 4 5 6 KPT06 F 16-26 P W A206 SHELL STYLE ENDBELLS LAYOUT CONTACT ROTATION MODIFIER ITT CANNON KPT SERIES MILITARY EXAMPLE

1 2 3 4 5 MS3116 F 16-26 P W SHELL STYLE ENDBELLS LAYOUT CONTACT ROTATION STEP 1: SELECT SHELL STYLE, PLUG OR RECEPTACLE

KPT02E* KPT07A* KPTB* KPT06* KPT08*

KPT00* KPT01* KPT07* PART NUMBER KEY: Commercial= (*) Military = (°) STEP 2: ENDBELLSSTEP 2: CHOOSE ENDBELL

PART NUMBER KEY: Commercial= (*) Military = (°) STEP 3: LAYOUTSTEP 3: CHOOSE LAYOUT

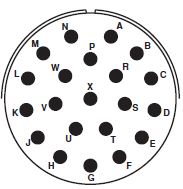

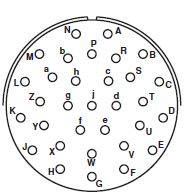

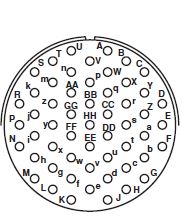

Contacts Rotations Layout KPT Rating Total 20 16 W X Y Z 8-2

I 2 2 58 122 - - 8-3

I 3 3 60 210 - - 8-3A

I 3 3 60 210 - - 8-4

I 4 4 45 - - - 8-33

I 3 3 90 - - - 10-6

I 6 6 90 - - - 10-98

I 6 6 90 180 240 270 12-3

II 3 3 - - 180 - 12-8

I 8 8 90 112 203 292 12-10

I 10 10 60 155 270 295 14-5

II 5 5 40 92 184 273 14-12

I 12 8 4 43 90 - - 14-15

I 15 14 1 17 110 155 234 14-18

I 18 18 15 90 180 270 14-19

I 19 19 30 165 315 - 16-8

II 8 8 54 152 180 331 16-23

I 23 22 1 158 270 - - 16-26

I 26 26 60 - 275 338 16-99

I 23 21 2 66 156 223 340 18-11

II 11 11 62 119 241 340 18-30

I 30 29 1 180 193 285 350 18-32

I 32 32 85 138 222 333 20-16

II 16 16 238 318 333 347 20-24

I 24 24 70 145 215 288 20-39

I 39 37 2 63 144 252 333 20-41

I 41 41 45 126 225 - 22-21

II 21 21 16 135 175 349 22-32

I 32 32 72 145 215 288 22-34

I 34 34 62 142 218 298 22-36

I 36 36 72 144 216 288 22-41

I 41 27 14 39 135 264 - 22-55

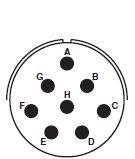

I 55 55 30 142 226 314 24-61

I 61 61 90 180 270 324

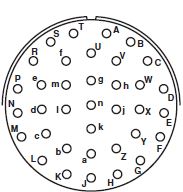

Read Less LAYOUTS BY NUMBER OF CONTACTS

CONTACT LEGEND: SERIES LEGEND:

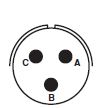

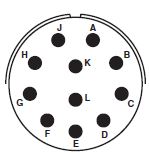

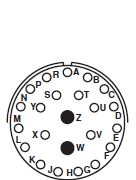

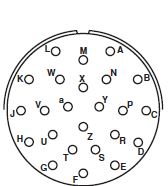

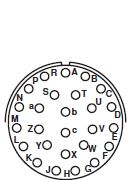

2 3 Contacts 4 5 6 Contacts

Shell Size/Layout 8-2 8-3 8-3A 8-33 12-3 8-4 14-5 10-6 10-98 # of Contacts 2-#20 3-#20 3-#20 3-#20 3-#16 4-#20 5-#16 6-#20 6-#20 Series

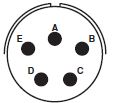

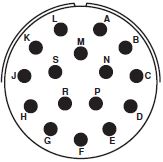

Service Rating I I I I II I II I I 8 Contacts 10 11 Contacts 12 15 16 Contacts

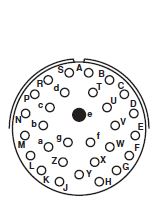

Shell Size/Layout 12-8 16-8 12-10 18-11 14-12 14-15 20-16 # of Contacts 8-#20 8-#16 10-#20 11-#16 8-#20 4-#16 1-#16; 14-#20 16-#16 Series

Service Rating I I I II I II I 18 19 21 Contacts 23 Contacts 24 Contacts 26

Shell Size/Layout 14-18 14-19 22-21 16-23 16-99 20-24 16-26 # of Contacts 18-#20 19-#20 21-#16 1-#16; 2-#16; 24-#20 26-#20 Series

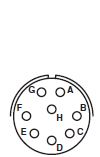

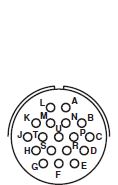

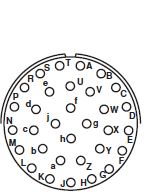

Service Rating I I II I I I I 30 Contacts 32 Contacts 34 Contacts 36

Shell Size/Layout 18-30 18-32 22-32 22-34 22-36 # of Contacts 1-#16; 29-#20 32-#20 32-#30 34-#20 36-#20 Series

Service Rating I I I I I 39 Contacts 41 Contacts 55 Contacts 61

Shell Size/Layout 20-39 20-41 22-41 22-55 24-61 # of Contacts 2-#16; 37-#20 41-#20 14-#16; 27-#20 55-#20 61-#20 Series

Service Rating I I I I I Read Less STEP 5: ROTATIONSTEP 5: CHOOSE ROTATION

See chart in STEP 3 (omit for normal) STEP 6: MODIFIERSTEP 6: CHOOSE MODIFIER (COMMERCIAL ONLY)

A71 = Electroless Nickel A206 = Conductive Black Zinc (RoHS) DN = Shrink Boot Adapter DZ = Shrink Boot Adapter |

|

STEP 1: STYLEITT CANNON KPT SERIES COMMERCIAL EXAMPLE

1 2 3 4 5 6 KPSE06 F 16-26 P W A206 SHELL STYLE ENDBELLS LAYOUT CONTACT ROTATION MODIFIER ITT CANNON KPT SERIES MILITARY EXAMPLE

1 2 3 4 5 6 MS3126 F 16-26 P W -L C SHELL STYLE ENDBELLS LAYOUT CONTACT ROTATION MODIFIER STEP 1: SELECT SHELL STYLE, PLUG OR RECEPTACLE

KPSE02E* KPSE07A* KPSE00* KPSE06* KPSE08*

KPSE01* KPSE07 PART NUMBER KEY: Commercial= (*) Military = (°) STEP 2: ENDBELLSSTEP 2: CHOOSE ENDBELL

PART NUMBER KEY: Commercial= (*) Military = (°) STEP 3: LAYOUTSTEP 3: CHOOSE LAYOUT

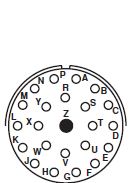

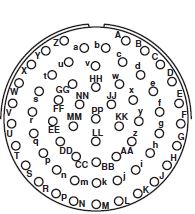

Contacts Rotations Layout KPSE Rating Total 20 16 W X Y Z 8-3A

I 3 3 60 210 - - 10-6

I 6 6 90 - - - 12-3

II 3 3 - - 180 - 12-10

I 10 10 60 155 270 295 14-5

II 5 5 40 92 184 273 14-12

I 12 8 4 43 90 - - 14-15

I 15 14 1 17 110 155 234 14-19

I 19 19 30 165 315 - 16-8

II 8 8 54 152 180 331 16-26

I 26 26 60 - 275 338 18-11

II 11 11 62 119 241 340 18-32

I 32 32 85 138 222 333 20-16

II 16 16 238 318 333 347 20-39

I 39 37 2 63 144 252 333 20-41

I 41 41 45 126 225 - 22-21

II 21 21 16 135 175 349 22-55

I 55 55 30 142 226 314 24-61

I 61 61 90 180 270 324

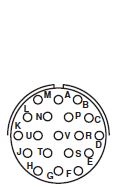

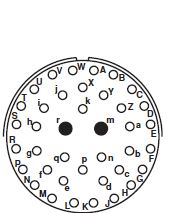

Read Less LAYOUTS BY NUMBER OF CONTACTS

CONTACT LEGEND: SERIES LEGEND:

2 3 Contacts 4 5 6 Contacts

Shell Size/Layout 8-2 8-3 8-3A 8-33 12-3 8-4 14-5 10-6 10-98 # of Contacts 2-#20 3-#20 3-#20 3-#20 3-#16 4-#20 5-#16 6-#20 6-#20 Series

Service Rating I I I I II I II I I 8 Contacts 10 11 Contacts 12 15 16 Contacts

Shell Size/Layout 12-8 16-8 12-10 18-11 14-12 14-15 20-16 # of Contacts 8-#20 8-#16 10-#20 11-#16 8-#20 4-#16 1-#16; 14-#20 16-#16 Series

Service Rating I I I II I II I 18 19 21 Contacts 23 Contacts 24 Contacts 26

Shell Size/Layout 14-18 14-19 22-21 16-23 16-99 20-24 16-26 # of Contacts 18-#20 19-#20 21-#16 1-#16; 2-#16; 24-#20 26-#20 Series

Service Rating I I II I I I I 30 Contacts 32 Contacts 34 Contacts 36

Shell Size/Layout 18-30 18-32 22-32 22-34 22-36 # of Contacts 1-#16; 29-#20 32-#20 32-#30 34-#20 36-#20 Series

Service Rating I I I I I 39 Contacts 41 Contacts 55 Contacts 61

Shell Size/Layout 20-39 20-41 22-41 22-55 24-61 # of Contacts 2-#16; 37-#20 41-#20 14-#16; 27-#20 55-#20 61-#20 Series

Service Rating I I I I I Read Less STEP 5: ROTATIONSTEP 5: CHOOSE ROTATION

See chart in STEP 3 (omit for normal) STEP 6: MODIFIERSTEP 6: CHOOSE MODIFIER (COMMERCIAL ONLY)

A71 = Electroless Nickel A206 = Conductive Black Zinc (RoHS) -LC = Less Crimp Contacts DN = Shrink Boot Adaptor DZ = Shrink Boot Adaptor |

|

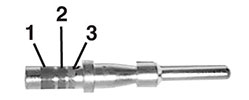

CONTACTSITT CANNON KPT SERIES CONTACTS - PINS

Size Wire Size AWG Pin Color Band 1 Color Band 2 Color Band 3 Wire Strip Lengths Wire Sealing Range Min. Wire Sealing Range Max. Wire Hole Filler Crimp Tools Use Turret Head Locator Color Insertion/ Extraction Tool M81969 20 20-24 M39029/ Red Yellow Black .250 (6.4) .047 (1.2) .083 (2.1) MS27488 -20-2 AF8 Hand Tool WA27F Air Powered TH1A Turret Head Red /17-03 (INS) 16 16-20 M39029/ Red Red Grey .250 (6.4) .066 (1.7) .109 (2.7) MS27488 -16-2 AF8 Hand Tool WA27F Air Powered TH1A Turret Head Blue /17-04 (INS) ITT CANNON KPT SERIES CONTACTS - SOCKETS

Size Wire Size AWG Socket Color Band 1 Color Band 2 Color Band 3 Wire Strip Lengths Wire Sealing Range Min. Wire Sealing Range Max. Wire Hole Filler Crimp Tools Use Turret Head Locator Color Insertion/ Extraction Tool M81969 20 20-24 M39029/ Red Green White .250 (6.4) .047 (1.2) .083 (2.1) MS27488 -20-2 AF8 Hand Tool WA27F Air Powered TH1A Turret Head Red /17-03 (INS) 16 16-20 M39029/ Red Yellow Violet .250 (6.4) .066 (1.7) .109 (2.7) MS27488 -16-2 AF8 Hand Tool WA27F Air Powered TH1A Turret Head Blue /17-04 (INS) All dimensions in inches (millimeters in parentheses) ITT CANNON KPT SERIES TOOLS

KPSE Crimp Kit  Kit contains:

COMPONENTSITT CANNON KPT SERIES COMPONENTS

Plugs Receptacles KPT KPSE KPT KPSE

|

|

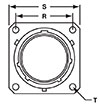

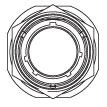

RECEPTACLESITT CANNON KPT SERIES RECEPTACLE STYLES

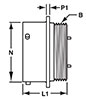

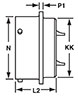

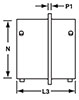

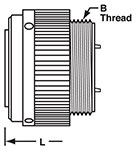

KPT00 KPT01 KPT02 KPTB All Types

Shell Size N Dia. Max +.003 (+/- 0.1) R (TP) S Max. T Dia. P1 P2 Q Max. L1 Max. B Thread Class 2A L2 Max. KK Dia. Max. L3 Max. 8 .471 (12.0) .594 (15.1) .828 (21.0) .120 (3.0) .062 (1.6) .094 (2.4) .958 (24.3) .850 (21.6) 0.4375-28UNEF .791 (20.1) .469 (11.9) 1.125 (38.6) 10 .588 (14.9) .719 (18.3) .954 (24.2) .120 (3.0) .062 (1.6) .094 (2.4) 1.082 (27.5) .850 (21.6) .5625-24UNEF .791 (20.1) .593 (15.1) 1.125 (38.6) 12 .748 (19.0) .812 (20.6) 1.047 (26.6) .120 (3.0) .062 (1.6) .094 (2.4) 1.176 (29.9) .850 (21.6) .6875-24UNEF .791 (20.1) .719 (18.3) 1.125 (38.6) 14 .873 (22.2) .906 (23.0) 1.141 (29.0) .120 (3.0) .062 (1.6) .094 (2.4) 1.270 (32.3) .850 (21.6) .8125-20UNEF .791 (20.1) .843 (21.4) 1.125 (38.6) 16 .998 (25.3) .969 (24.6) 1.234 (31.3) .120 (3.0) .062 (1.6) .094 (2.4) 1.364 (34.6) .850 (21.6) .9375-20UNEF .791 (20.1) .969 (24.6) 1.125 (38.6) 18 1.123 (28.5) 1.062 (27.0) 1.328 (33.7) .120 (3.0) .062 (1.6) .094 (2.4) 1.458 (37.0) .850 (21.6) 1.0625-18UNEF .791 (20.1) 1.093 (27.8) 1.125 (38.6) 20 1.248 (31.7) 1.156 (29.4) 1.453 (36.9) .120 (3.0) .094 (2.4) .115 (2.9) 1.582 (40.2) 1.057 (26.8) 1.1875-18UNEF .891 (22.6) 1.219 (31.0) 1.406 (35.7) 22 1.373 (34.9) 1.250 (31.8) 1.578 (40.1) .120 (3.0) .094 (2.4) .115 (2.9) 1.708 (43.4) 1.057 (26.8) 1.3125-18UNEF .891 (22.6) 1.343 (34.1) 1.406 (35.7) 24 1.498 (38.0) 1.375 (34.9) 1.703 (43.3) .147 (3.7) .094 (2.4) .115 (2.9) 1.832 (46.5) 1.057 (26.8) 1.4375-18UNEF .891 (22.6) 1.469 (37.3) 1.406 (35.7) All dimensions are shown in inches (millimeters in parentheses) ITT CANNON KPT SERIES ENDBELL STYLES

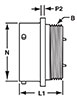

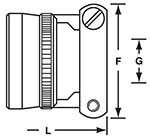

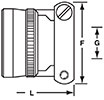

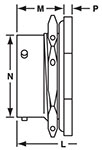

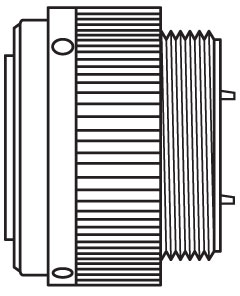

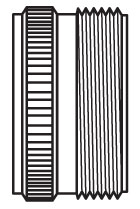

A (Not MS) E (MS) F (MS) P (MS) J (MS) A Endbells E Endbells F/B Endbells P Endbells J Endbell Shell Size F Min. L Max. B Thread UNEF-2A L Max. KK Max. F Min. G Min. L F L Max. L XX Min. XX Max. 8 .335 (8.5) 1.444 (36.7) .5000-28 1.328 (33.7) .608 (15.4) .828 (21.0) .115 (2.9) 1.922 (48.8) .317 (8.1) 1.453 (36.9) 2.271 (57.7) .168 (4.3) .230 (5.8) 10 .466 (11.8) 1.444 (36.7) .6250-24 1.328 (33.7) .734 (18.6) .891 (22.6) .178 (4.5) 1.922 (48.8) .434 (11.0) 1.453 (36.9) 2.271 (57.7) .205 (5.2) .312 (7.9) 12 .591 (15.0) 1.444 (36.7) .7500-20 1.328 (33.7) .858 (21.8) 1.016 (25.8) .302 (7.7) 1.922 (48.8) .548 (13.9) 1.453 (36.9) 2.411 (61.2) .338 (8.6) .442 (11.2) 14 .705 (17.9) 1.444 (36.7) .8750-20 1.328 (33.7) .984 (25.0) 1.141 (29.0) .365 (9.3) 1.922 (48.8) .673 (17.1) 1.453 (36.9) 2.599 (66.0) .416 (10.6) .539 (13.7) 16 .830 (21.1) 1.444 (36.7) 1.0000-20 1.328 (33.7) 1.110 (28.2) 1.203 (30.6) .490 (12.4) 2.047 (52.0) .798 (20.3) 1.453 (36.9) 2.943 (74.8) .550 (14.0) .616 (15.6) 18 .948 (24.1) 1.444 (36.7) 1.1875-18 1.328 (33.7) 1.234 (31.3) 1.469 (37.3) .615 (15.6) 2.078 (52.8) .899 (22.8) 1.453 (36.9) 3.172 (80.6) .600 (15.2) .672 (17.1) 20 1.043 (26.5) 1.728 (43.9) 1.1875-18 1.531 (38.9) 1.360 (34.5) 1.469 (37.3) .615 (15.6) 2.344 (59.5) 1.024 (26.0) 1.627 (42.5) 3.610 (91.7) .635 (16.1) .747 (19.0) 22 1.198 (30.4) 1.728 (43.9) 1.4375-18 1.531 (38.9) 1.484 (37.7) 1.656 (42.1) .740 (18.8) 2.344 (59.5) 1,149 (29.2) 1.672 (42.5) 3.766 (95.7) .670 (17.0) .846 (21.5) 24 1.293 (32.8) 1.738 (44.1) 1.4375-18 1.594 (40.5) 1.610 (40.9) 1.750 (44.5) .790 (20.1) 2.406 (61.1) 1.274 (32.4) 1.734 (44.0) 3.985 (101.2) .740 (18.8) .894 (22.7) All dimensions are shown in inches (millimeters in parentheses) PLUGSITT CANNON KPT SERIES STRAIGHT PLUGS

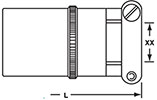

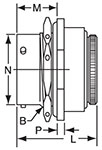

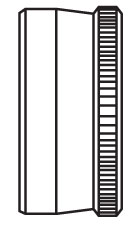

KPT06 KPT06A KPT06E KPT06F 06 06A 06E 06F Shell Size Q Max. L Max. B F Min. L Max. B Thread UNEF-2A L Max KK Max. F Max G Min L Max 8 .782 .841 (21.4) .4375-28UNEF .335 (8.5) 1.440 (36.6) .5000-28 1.328 (33.7) .608 (15.4) .828 (21.0) .115 (2.9) 1.906 (48.4) 10 .926 .841 (21.4) .5625-24UNEF .466 (11.8) 1.440 (36.6) .6250-24 1.328 (33.7) .734 (18.6) .891 (22.6) .178 (4.5) 1.906 (48.4) 12 1.043 .841 (21.4) .6875-24UNEF .591 (15.0) 1.440 (36.6) .7500-20 1.328 (33.7) .858 (21.8) 1.016 (25.8) .302 (7.7) 1.906 (48.4) 14 1.183 .841 (21.4) .8125-24UNEF .705 (17.9) 1.440 (36.6) .8750-20 1.328 (33.7) .984 (25.0) 1.141 (29.0) .365 (9.3) 1.906 (48.4) 16 1.305 .841 (21.4) .9375-20UNEF .830 (21.1) 1.440 (36.6) 1.0000-20 1.328 (33.7) 1.110 (28.2) 1.203 (30.6) .490 (12.4) 2.047 (52.0) 18 1.391 .841 (21.4) 1.0625-18UNEF .948 (24.1) 1.662 (42.2) 1.1875-18 1.328 (33.7) 1.234 (31.3) 1.469 (37.3) .615 (15.6) 2.078 (52.8) 20 1.531 .986 (25.0) 1.1875-18UNEF 1.043 (26.5) 1.662 (42.2) 1.1875-18 1.453 (36.9) 1.360 (34.5) 1.469 (37.3) .615 (15.6) 2.250 (57.2) 22 1.656 .986 (25.0) 1.3125-18UNEF 1.198 (30.4) 1.662 (42.2) 1.4375-18 1.453 (36.9) 1.484 (37.7) 1.656 (42.1) .740 (18.8) 2.250 (57.2) 24 1.770 .986 (25.0) 1.4375-18UNEF 1.293 (32.8) 1.672 (42.5) 1.4375-18 1.510 (38.4) 1.610 (40.9) 1.750 (44.5) .790 (20.1) 2.312 (58.7) KPT06P* KPT06J 06P 06J Shell Size F L Min. L Cable QO Cable QO 8 .317 (8.1) 1.500 (38.1) 2.271 (57.7) .168 (4.3) .230 (5.8) 10 .434 (11.0) 1.500 (38.1) 2.271 (57.7) .205 (5.2) .312 (7.9) 12 .548 (13.9) 1.500 (38.1) 2.411 (61.2) .338 (8.6) .442 (11.2) 14 .673 (17.1) 1.500 (38.1) 2.599 (66.0) .416 (10.6) .539 (13.7) 16 .798 (20.3) 1.500 (38.1) 2.943 (74.8) .550 (14.0) .616 (15.6) 18 .899 (22.8) 1.500 (38.1) 3.172 (80.6) .600 (15.2) .672 (17.1) 20 1.024 (26.0) 1.609 (40.9) 3.610 (91.7) .635 (16.1) .747 (19.0) 22 1.149 (29.2) 1.609 (40.9) 3.766 (95.7) .670 (17.0) .846 (21.5) 24 1.274 (32.4) 1.687 (42.8) 3.985 (101.2) .740 (18.8) .849 (21.6) ITT CANNON KPT SERIES RIGHT ANGLE PLUGS

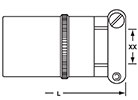

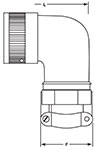

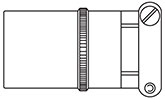

KPT08A, B, E, F KPT08P

08 Style With Clamp With Wire Seal A B

E

F

08E/A/B/F 08P Shell Size Q Max F Max L Max F Max L Min 8 .765 (19.4) .812 (20.6) 1.842 (46.8) - - 10† .840 (21.3) .875 (22.2) 1.937 (49.2) .252 (6.4) 1.380 (35.1) 12 .999 (25.4) 1.062 (27.0) 1.937 (49.2) .252 (6.4) 1.567 (39.8) 14 1.139 (28.9) 1.156 (29.4) 2.124 (53.9) .283 (7.2) 1.567 (39.8) 16 1.261 (32.0) 1.250 (31.8) 2.203 (56.0) .355 (9.0) 1.567 (39.8) 18 1.337 (34.0) 1.469 (37.3) 2.380 (60.5) .530 (13.5) 1.755 (44.6) 20 1.477 (37.5) 1.469 (37.3) 2.629 (66.8) .562 (14.3) 1.782 (45.3) 22 1.602 (40.7) 1.680 (42.7) 2.629 (66.8) .562 (14.3) 1.782 (45.3) 24† 1.723 (43.8) 1.688 (42.9) 2.895 (73.5) .610 (15.5) 2.087 (53.0) † A 2-piece backshell may be used, contact us for details. All dimensions are shown in inches (millimeters in parentheses) ITT CANNON KPT SERIES ENDBELL STYLES

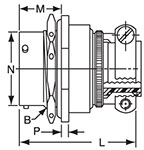

A (Not MS) E (MS) F (MS) P (MS) J (MS) A Endbells E Endbells F/B Endbells P Endbells J Endbell Shell Size F Min. L Max. B Thread UNEF-2A L Max. KK Max. F Min. G Min. L F L Max. L XX Min. XX Max. 8 .335 (8.5) 1.444 (36.7) .5000-28 1.328 (33.7) .608 (15.4) .828 (21.0) .115 (2.9) 1.922 (48.8) .317 (8.1) 1.453 (36.9) 2.271 (57.7) .168 (4.3) .230 (5.8) 10 .466 (11.8) 1.444 (36.7) .6250-24 1.328 (33.7) .734 (18.6) .891 (22.6) .178 (4.5) 1.922 (48.8) .434 (11.0) 1.453 (36.9) 2.271 (57.7) .205 (5.2) .312 (7.9) 12 .591 (15.0) 1.444 (36.7) .7500-20 1.328 (33.7) .858 (21.8) 1.016 (25.8) .302 (7.7) 1.922 (48.8) .548 (13.9) 1.453 (36.9) 2.411 (61.2) .338 (8.6) .442 (11.2) 14 .705 (17.9) 1.444 (36.7) .8750-20 1.328 (33.7) .984 (25.0) 1.141 (29.0) .365 (9.3) 1.922 (48.8) .673 (17.1) 1.453 (36.9) 2.599 (66.0) .416 (10.6) .539 (13.7) 16 .830 (21.1) 1.444 (36.7) 1.0000-20 1.328 (33.7) 1.110 (28.2) 1.203 (30.6) .490 (12.4) 2.047 (52.0) .798 (20.3) 1.453 (36.9) 2.943 (74.8) .550 (14.0) .616 (15.6) 18 .948 (24.1) 1.444 (36.7) 1.1875-18 1.328 (33.7) 1.234 (31.3) 1.469 (37.3) .615 (15.6) 2.078 (52.8) .899 (22.8) 1.453 (36.9) 3.172 (80.6) .600 (15.2) .672 (17.1) 20 1.043 (26.5) 1.728 (43.9) 1.1875-18 1.531 (38.9) 1.360 (34.5) 1.469 (37.3) .615 (15.6) 2.344 (59.5) 1.024 (26.0) 1.627 (42.5) 3.610 (91.7) .635 (16.1) .747 (19.0) 22 1.198 (30.4) 1.728 (43.9) 1.4375-18 1.531 (38.9) 1.484 (37.7) 1.656 (42.1) .740 (18.8) 2.344 (59.5) 1,149 (29.2) 1.672 (42.5) 3.766 (95.7) .670 (17.0) .846 (21.5) 24 1.293 (32.8) 1.738 (44.1) 1.4375-18 1.594 (40.5) 1.610 (40.9) 1.750 (44.5) .790 (20.1) 2.406 (61.1) 1.274 (32.4) 1.734 (44.0) 3.985 (101.2) .740 (18.8) .894 (22.7) All dimensions are shown in inches (millimeters in parentheses) JAM NUT RECEPTACLESITT CANNON KPT SERIES JAM NUT RECEPTACLES

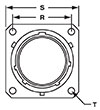

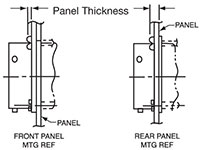

KPT07 KPT07A KPT07E KPT07F KPT07P 07 07A 07E/F 07P Shell Size B Thread UNEF -2A

Panel Thick ness Min Panel Thick ness Max

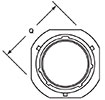

8 .5625-24 0.691 (17.6) .471 (12.0) .117 (3.0) .750 (19.1) .954 (24.2) .062 (1.6) .125 (3.2) .889 (22.6) 1.344 (34.1) 1.906 (48.4) .317 (8.1) 1.391 (35.3) 10 .6875-24 0.691 (17.6) .588 (14.9) .117 (3.0) .875 (22.2) 1.078 (27.4) .062 (1.6) .125 (3.2) .889 (22.6) 1.344 (34.1) 1.906 (48.4) .434 (11.0) 1.391 (35.3) 12 .8750-20 0.691 (17.6) .748 (19.0) .117 (3.0) 1.065 (27.0) 1.266 (32.2) .062 (1.6) .125 (3.2) .889 (22.6) 1.344 (34.1) 1.906 (48.4) .548 (13.9) 1.391 (35.3) 14 1.0000-20 0.691 (17.6) .873 (22.2) .117 (3.0) 1.188 (30.2) 1.391 (35.3) .062 (1.6) .125 (3.2) .889 (22.6) 1.344 (34.1) 1.906 (48.4) .673 (17.1) 1.391 (35.3) 16 1.1250-18 0.691 (17.6) .988 (25.1) .117 (3.0) 1.312 (33.3) 1.516 (38.5) .062 (1.6) .125 (3.2) .889 (22.6) 1.344 (34.1) 2.047 (52.0) .798 (20.3) 1.391 (35.3) 18 1.2500-18 0.691 (17.6) 1.123 (28.5) .117 (3.0) 1.438 (36.5) 1.641 (41.7) .062 (1.6) .125 (3.2) .889 (22.6) 1.344 (34.1) 2.078 (52.8) .899 (22.8) 1.391 (35.3) 20 1.3750-18 0.879 (22.3) 1.248 (31.7) .148 (3.8) 1.562 (39.7) 1.828 (46.4) .062 (1.6) .250 (6.4) 1.108 (28.1) 1.594 (40.5) 2.328 (59.1) 1.024 (26.0) 1.641 (41.7) 22 1.5000-18 0.879 (22.3) 1.373 (34.9) .148 (3.8) 1.688 (42.9) 1.954 (49.6) .062 (1.6) .250 (6.4) 1.108 (28.1) 1.594 (40.5) 2.328 (59.1) 1.149 (29.2) 1.641 (41.7) 24 1.6250-18 0.912 (23.2) 1.498 (38.0) .148 (3.8) 1.812 (46.0) 2.078 (52.8) .062 (1.6) .250 (6.4) 1.141 (29.0) 1.641 (41.7) 2.453 (62.3) 1.274 (32.4) 1.703 (43.3) All dimensions are shown in inches (millimeters in parentheses) PANEL CUTOUTS/THICKNESSITT CANNON KPT SERIES PANEL CUTOUTS/THICKNESS

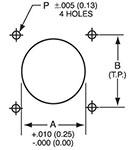

KPT00

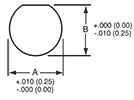

Panel Thickness Shell Size A B P +/-.005 Screw Size KPT/KPSE 00/02 KPTB 8 .618 (15.7) .594 (15.1) .125 (3.2) #4 .087 (2.2) .218 (5.5) 10 .735 (18.7) .719 (18.3) .125 (3.2) #4 .087 (2.2) .218 (5.5) 12 .859 (21.8) .812 (20.6) .125 (3.2) #4 .087 (2.2) .218 (5.5) 14 .985 (25.0) .906 (23.0) .125 (3.2) #4 .087 (2.2) .218 (5.5) 16 1.113 (28.3) .969 (24.6) .125 (3.2) #4 .087 (2.2) .218 (5.5) 18 1.235 (31.4) 1.062 (27.0) .125 (3.2) #4 .087 (2.2) .218 (5.5) 20 1.361 (34.6) 1.156 (29.4) .125 (3.2) #4 .212 (5.4) .334 (8.5) 22 1.485 (37.7) 1.250 (31.8) .125 (3.2) #4 .212 (5.4) .334 (8.5) 24 1.611 (40.9) 1.375 (34.9) .155 (3.9) #6 .212 (5.4) .311 (7.9) KPT07

Panel Thickness Shell Size A +010-.000 (+.25 - .00) B +010-.000 (+.25 - .00) Min Max 8 .578 (14.7) .540 (13.7) .062 (1.6) .125 (3.2) 10 .703 (17.9) .665 (16.9) .062 (1.6) .125 (3.2) 12 .890 (22.6) .828 (21.0) .062 (1.6) .125 (3.2) 14 1.015 (25.8) .952 (24.2) .062 (1.6) .125 (3.2) 16 1.140 (29.0) 1.076 (27.3) .062 (1.6) .125 (3.2) 18 1.265 (32.1) 1.201 (30.5) .062 (1.6) .125 (3.2) 20 1.390 (35.3) 1.326 (33.7) .062 (1.6) .250 (6.4) 22 1.515 (38.5) 1.451 (36.9) .062 (1.6) .250 (6.4) 24 1.640 (41.7) 1.576 (40.0) .062 (1.6) .250 (6.4) All dimensions are shown in inches (millimeters in parentheses) |

|

ITT CANNON KPT SERIES ACCESSORIES

Flange Mount Receptacle Accessories Gasket Nut Plate Sealing Screws Dummy Receptacle

Dust Caps Plug Dust Cap Receptacle Flange Dust Cap Receptacle Jam Nut Dust Cap Cable Clamp

Flange Mount Receptacle Accessories Dust Caps Shell Size Gasket Nut Plate Sealing Screws Dummy Receptacles Plugs Flanged Receptacles Jam Nut Receptacles Cable Clamp for A Endbells 8 CMD02-8* M85049/95-8A S440-1/2 MS3115-8** MS3180-8C† MS3181-8C† MS3181-8N† MS3057-3A 10 CMD02-10* M85049/95-10A S440-1/2 MS3115-10** MS3180-10C† MS3181-10C† MS3181-10N† MS3057-4A 12 CMD02-12* M85049/95-12A S440-1/2 MS3115-12** MS3180-12C† MS3181-12C† MS3181-12N† MS3057-6A 14 CMD02-14* M85049/95-14A S440-1/2 MS3115-14** MS3180-14C† MS3181-14C† MS3181-14N† MS3057-8A 16 CMD02-16* M85049/95-16A S440-1/2 MS3115-16** MS3180-16C† MS3181-16C† MS3181-16N† MS3057-10A 18 CMD02-18* M85049/95-18A S440-1/2 MS3115-18** MS3180-18C† MS3181-18C† MS3181-18N† MS3057-12A 20 CMD02-20* M85049/95-20A S440-1/2 MS3115-20** MS3180-20C† MS3181-20C† MS3181-20N† MS3057-12A 22 CMD02-22* M85049/95-22A S440-1/2 MS3115-22** MS3180-22C† MS3181-22C† MS3181-22N† MS3057-16A 24 CMD02-24* M85049/95-24A S440-1/2 MS3115-24** MS3180-24C† MS3181-24C† MS3181-24N† MS3057-16A * Add C for conductive type ** Select Plating W = Olive drab over cadmium A = Anodized L = Electroless nickel † = Dustcap Plating Blank = Olive drab over cadmium A = Anodized L = Electroless Nickel Z = Zinc Nickel |

|

KPT SOLDER CONTACTSITT CANNON KPT SERIES KPT SOLDER CONTACTS

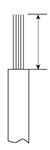

STEP 1: Slide the rear accessories over the wire bundle in the proper sequence for re-assembly: cable clamp and/or endbell first, then ferrule, and (if used) the coupling nut. STEP 2: Insert individual wires through the proper holes in the grommet. STEP 3: Solder wires to appropriate contacts on the rear of the connector. ITT Cannon document RPI234 covers standard soldering practices and is available upon request. STEP 4: Fixture the connector for re-assembly using the endbell assembly tools or a mating connector with contacts installed. STEP 5: Slide the grommet down the wires (lubricating the grommet with isopropyl alcohol will help). STEP 6: Fill all unused grommet cavities with a wire hole filler to maintain the sealing integrity of the connector. STEP 7: Slide coupling nut, ferrule, and endbell accessories over rear of the connector and tighten. See chart below for Torque: Size Torque (Inch/lbs) 8, 10, 12, 14 10-15 16, 18 15 - 25 20, 22, 24 25 - 35 KPSE CRIMP TOOL OPERATIONITT CANNON KPT SERIES KPSE CRIMP TOOL OPERATION

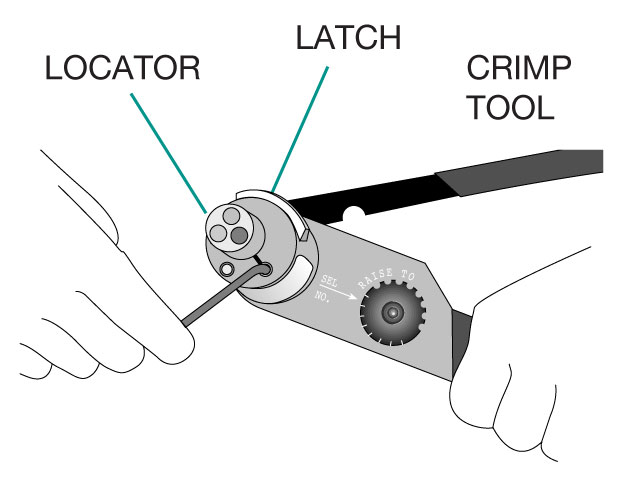

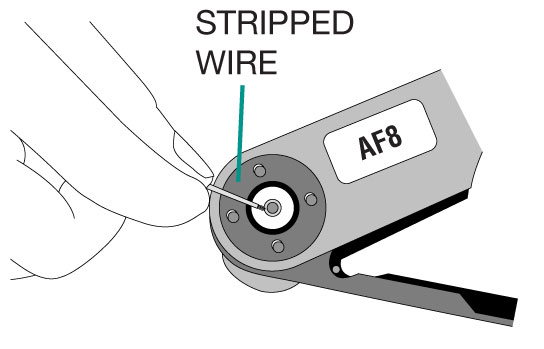

STEP 1: Strip the wires to the appropriate length. Contact Size Strip Length 20 1/4" (6.4mm) 16 1/4" (6.4mm)

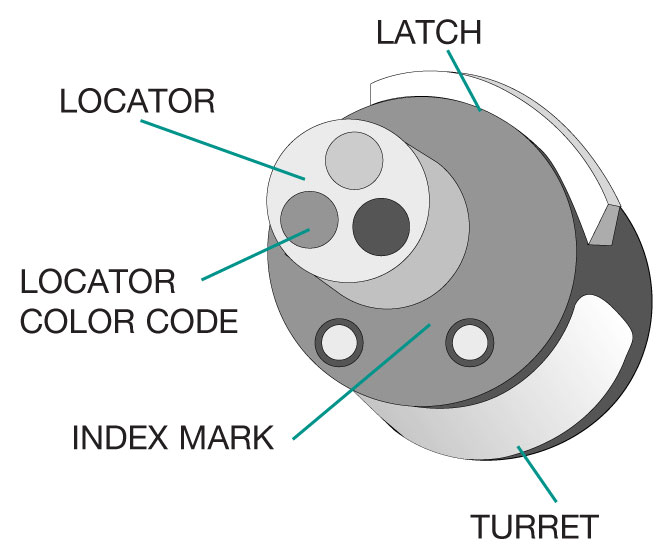

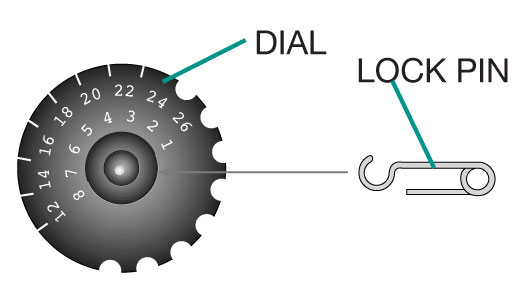

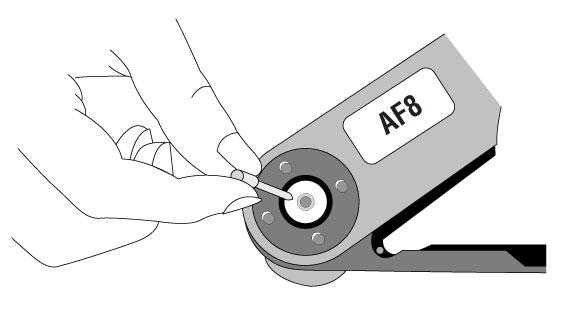

STEP 2: Open the AF8 (M22520/1-01) crimp tool by squeezing the handles. Push the latch on TH1A (M22520/1-02) to pop up the locator on the turret. Attach the turret to the AF8 crimp tool using the two captive hex bolts in the turret. STEP 3: Select the proper locator position for your contact by rotating the locator until the proper color is aligned with the index mark. Push locator back down until it snaps into position. Contact Size Locator Color 20 Red 16 Blue

STEP 4: Adjust dial for proper wire gauge. To change the dial setting, remove the lock pin and lift center of dial. Turn to the desired wire gauge. Replace lock pin on dial. STEP 5: Cycle the tool before inserting the contact to be sure the tool is in the open position. Drop the contact, mating end first, into the crimp cavity of the tool. Squeeze the tool handle just enough to grip the contact without actually crimping it. STEP 6: Insert the stripped wire into the contact with a slight twisting motion. Be sure all wire strands are inside the contact. Squeeze the handle to cycle the tool. The handle will not release until the contact is completely crimped. STEP 7: Remove the crimped contact. Pull on the wire slightly to be sure it is properly crimped. Be sure the contact is not bent or damaged in any way.

CONTACT INSERTIONITT CANNON KPT SERIES CONTACT INSERTION

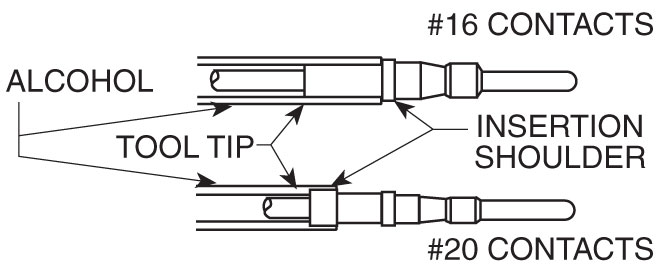

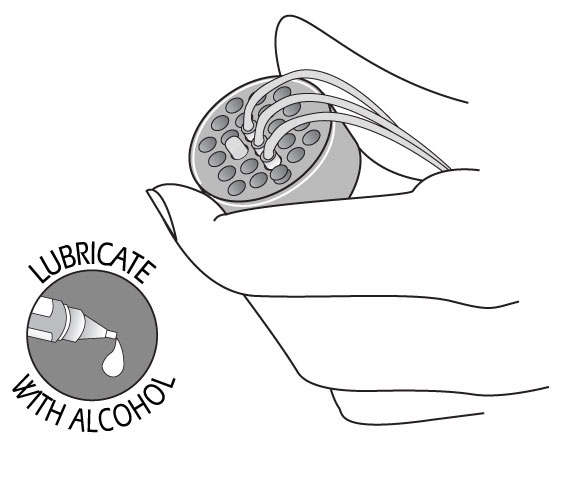

STEP 1: Slide the rear accessories over the wire bundle in the proper sequence for re-assembly: cable clamp and/or endbell first, then ferrule, and coupling nut. STEP 2: Using the proper insertion tool, slide the tool over the wire side of the contact until the tool bottoms on the contact. The tool for size 16 contacts pushes against the shoulder of the contact. The rear, or insulation support, of the size 20 contacts presses against an internal shoulder in the tool tip. STEP 3: Dip the contact and tool tip in isopropyl alcohol (do not use any lubricant other than isopropyl alcohol). Hold the tool perpendicular to the rear of the connector. Beginning with the center cavity and working outward in a circular pattern, insert the wired contact into the rear of the connector until the contact snaps into place. A light pull on the wire will assure that the contact is locked securely.

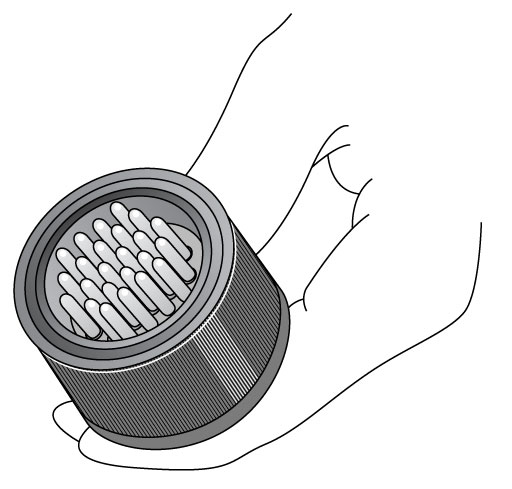

STEP 4: Fill any unused cavities with contacts. A wire hole filler must be inserted into the grommet behind the unused contacts to maintain the sealing integrity of the connector. Trim off excess. STEP 5: Check the mating face of the connector to ensure that all the same size contacts are on the same plane (fully inserted). If not, the contact is not fully inserted. Remove the contact using the proper extraction tool and procedure and reinsert. Do not attempt to reinsert the insertion tool to correct the problem. STEP 6: Fixture the connector for re-assembly using the endbell assembly tools or a mating connector with contacts installed. Slide the connector accessories back down the cable over the rear of the connector and tighten. Torque as follows: Size Torque (Inches/lbs) 8, 10, 12, 14 10 - 15 16, 18 15 - 25 20, 22, 24 25 - 35 CONTACT EXTRACTIONITT CANNON KPT SERIES CONTACT EXTRACTION

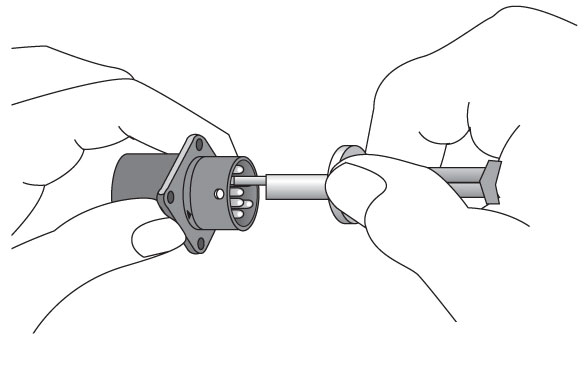

STEP 1: Remove the endbell accessories and slide them back over the wires. STEP 2: Use the proper extraction tool. STEP 3: On the mating face of the connector, insert the tool over the contact and into the insulator until the tool bottoms. While keeping an even pressure against the tool, push the plunger on the tool shaft forward with your thumb and index finger. This will release the contact from the retention tine and push it toward the rear of the connector. STEP 4: Carefully remove extraction tool from the connector. Pull the wire by hand to completely remove the contact from the rear of the connector. Specifications subject to change. |

Philadelphia

19116

Click here for the contact information of the branch nearest you.

= 16

= 16 = 20

= 20 = Commercial Crimp

= Commercial Crimp = Commercial & Military Crimp

= Commercial & Military Crimp