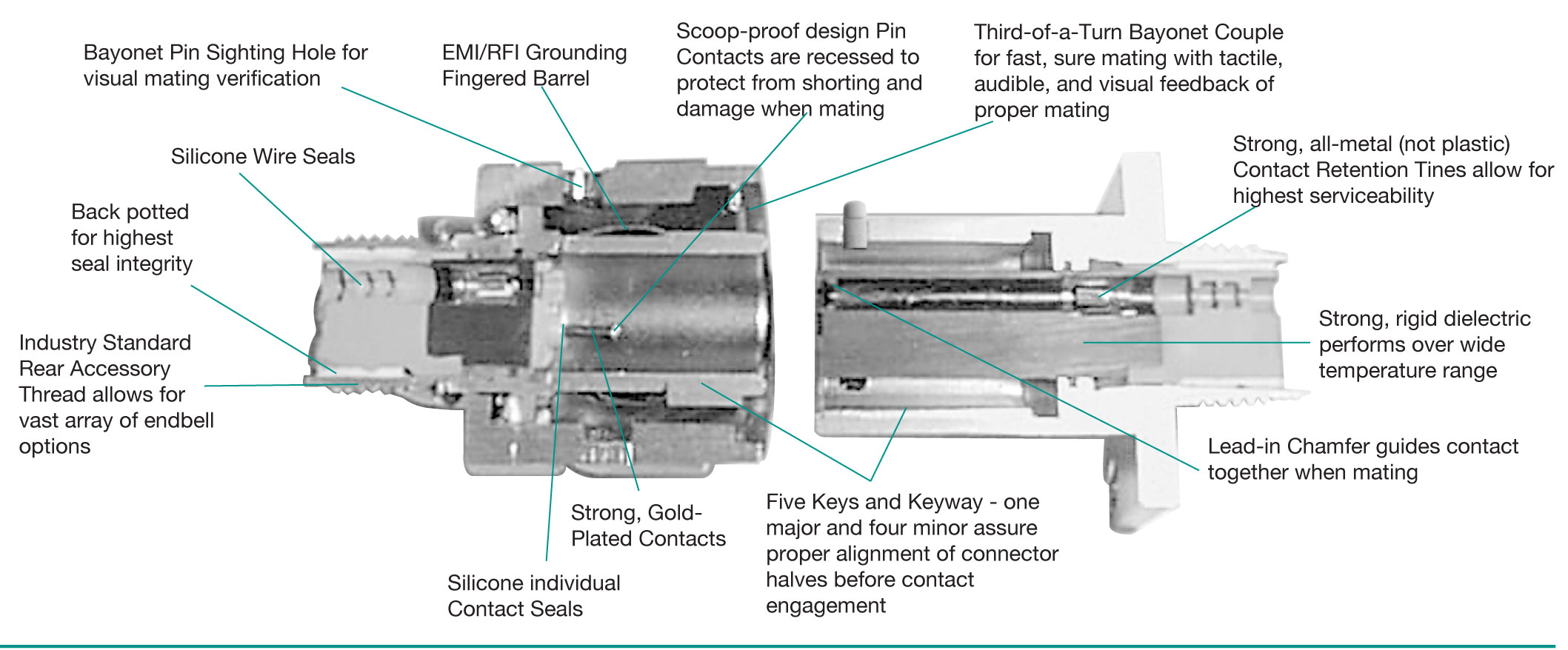

ITT Cannon KJL Series 38999-Style Series I Miniature Circular Connectors

INTERMATEABLE WITH ALL 38999-STYLE SERIES I CONNECTORS

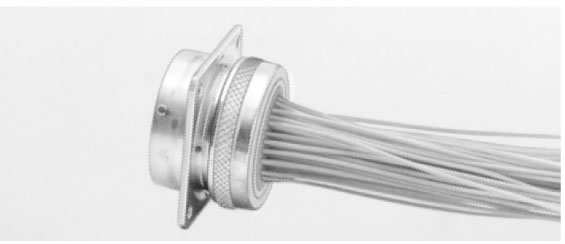

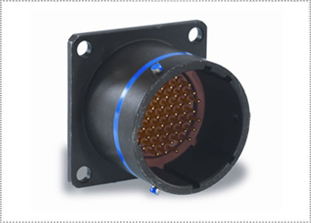

ITT Cannon KJL 38999-Style Series I connectors offer high-density contact arrangements in a lightweight miniature circular connector. KJL series connectors were originally designed for military vehicles and are now an industry-standard for military and aerospace harsh environment applications, built to tackle the most extreme conditions with exceptional versatility.

They are quick-mating, have three-point bayonet coupling, are environmentally sealed, and operate across a wide temperature range.

These 38999-Style connectors are intermateable with Souriau connectors and 38999-Style Series I connectors. For full details on ITT Cannon 38999-Style Series I connectors, please see the product specifications below.

|

FEATURESITT CANNON KJL SERIES FEATURES

MATERIALS & FINISHESITT CANNON KJL SERIES MATERIALS & FINISHES

Shell Aluminum Alloy

Bayonet Pins Passivated stainless steel per QQ-S-763

Plating A - Clear chromate over cadmium over electroless nickel per QQ-P-416

B - Olive drab chromate over cadmium over electroless nickel per QQ-P-416 A296 - Black Zinc Cobalt F - Electroless nickel per QQ-N-290 (N - Commercial) Contacts Copper alloy

Platings Gold plate, 50 microinches per MIL-G-45204 type II, grade C, class 1

Insulator Hard plastic wafer which contains metal retention tines for high-reliability retention of

crimp contacts

Grommet & Seals Silicone-based elastomer

Grommet & Springs Beryllium copper (grounded plug only)

ELECTRICAL DATAITT CANNON KJL SERIES ELECTRICAL DATA

Test Voltage (Unmated Conditions)Service Rating Test Voltages N M I II Sea Level 1000 1300 1800 2300 100,000 feet 200 200 200 200 Operating Voltage Service Rating N M I II Operating Voltage 300VAC/450VDC 400VAC/500VDC 600VAC/850VDC 900VAC/1250VDC Current Rating by contact size and wire accomodations (Test Amps) Wire Size 22D 22M* 22* 20 16 12 28 1.5 1.5 - - - - 26 2.0 2.0 2.0 - - - 24 3.0 3.0 3.0 3.0 - - 22 5.0 - 5.0 5.0 - - 20 - - - 7.5 7.5 - 18 - - - - 10.0 - 16 - - - - 13.0 - 14 - - - - - 17.0 12 - - - - - 23.0 Contact Resistance of mated contacts end-to-end Contact Size/Wire Size Maximum Millivolt Drop 22D 73 22M* 45 22* 73 20 55 16 49 12 42 Insulation Resistance 5,000 megohms minimum

*Inactive for new designs MECHANICALITT CANNON KJL SERIES MECHANICAL

Operating Temperature A Plating -65°C to 150°C (-85°F to 302°F)

B Plating -65°C to 175°C (-85°F to 347°F) F (N) Plating -65°C to 200°C (-85°F to 392°F) Sealing Against sand, dust per MIL-STD-202 & ice

Wire Sealing Range Contact Size Minimum (Inches) Maximum (Inches) Minimum (mm) Maximum (mm) 22D 0.0300 0.054 0.76 1.37 22M* 0.030 0.050 0.76 1.27 22* 0.034 0.060 0.86 1.52 20 0.040 0.083 1.02 2.11 16 0.065 0.109 1.65 2.77 12 0.097 0.142 2.46 3.61 Insulation Strip Length Contact Size Strip Length Inches (mm) 22*, 22D, or 22M* .125 (3.18) 20 .188 (4.77) 16 .188 (4.77) 12 .188 (4.77) Mating Life 500 cycles minimum

Salt Spray Finish A: 48 hour per MIL-STD-1344A method 1001 condition B

Finish B: 500 hour per MIL-STD 1344A method 1001 condition C Finish F: 48 hour per MIL-STD-1344A method 1001 condition B Heat Finish A: 150°C (302°F)

Finish B: 175°C (347°F) Finish F: 200°C (392°F) 1000 hours to MIL-STD-1344 method 1005 Chemical Resistance Lubricating oils, hydraulic fluids, coolants, deicing fluids per MIL-STD-1344A Method 1016 condition a-1

Sine Vibration 30g at ambient temperature with simulated accessory load

Random Vibration 49.5 grms at ambient temperatures

Shock 300g ±15% half sine wave magnitude for 3 ±1 milliseconds

EMI Shielding Effectiveness 100 MHz to 10 GHz - minimum attenuation of 50dB effectiveness

Contact Type Crimp, fiber optic, co-ax, twinax, or printed circuit

Number of Circuits 3 to 128

Contact Insertion Insertion from rear of connector with simple plastic or high-quality metal hand

tool. Extraction from rear with simple plastic or high-quality metal hand tools.

Contact Retention Per MIL-DTL-38999 tested to MIL-STD-1344A method 2007

Contact Axial Load Newtons +/-10% Axial Load Pounds +/-10% 22*, 22D or 22M* 44 10 20 67 15 16 112 25 12 111 25 NOTE: CT/CA/MS receptacle contacts are bonded into the insulator. Polarization Five keyways with optional minor keyways rotation (Note insert and main keyway remain fixed)

|

|

ITT CANNON KJL SERIES APPLICATIONS

|

|

STEP 1: STYLEITT CANNON KJL SERIES MILITARY PART NUMBER EXAMPLE

1 2 3A 4 3B 5 6 7 MS27468 T 25 F 35 P -LC SHELL STYLE CLASS SIZE PLATING LAYOUT CONTACT POLARIZATION MODIFIER ITT CANNON KJL SERIES COMMERCIAL PART NUMBER EXAMPLE

1 2 3A 4 3B 5 6 7 KJL7 T 25 N 35 P N L/C SHELL STYLE CLASS SIZE PLATING LAYOUT CONTACT POLARIZATION MODIFIER STEP 1: CHOOSE STYLE

M27466 MS27656 MS27467

MS27468 MS27505

STEP 2: CLASSSTEP 2: CHOOSE CLASS

T = No Rear Accessories F = Straight Strain Relief (KJL only, not MIL Spec) STEP 3: LAYOUTSTEP 3: CHOOSE LAYOUT

*Listed by shell size

Contacts Layout Number Service Rating Total Number 22D 22M 22 20 16 12 8 9-6+ M 6 - 6 - - - - - 9-35 M 6 6 - - - - - - 9-98 I 3 - - - 3 - - - 11-4 I 4 - - - 4 - - - 11-5 I 5 - - - 5 - - - 11-13+ M 13 - 13 - - - - - 11-35 M 13 13 - - - - - - 11-98 I 6 - - - 6 - - - 11-99 I 7 - - - 7 - - - 13-4 I 4 - - - - 4 - - 13-8 I 8 - - - 8 - - - 13-22+ M 22 - 22 - - - - - 13-35 M 22 22 - - - - - - 13-98 I 10 - - - 10 - - - 15-5 II 5 - - - - 5 - - 15-15 I 15 - - - 14 1 - - 15-18 I 18 - - - 18 - - - 15-19 I 19 - - - 19 - - - 15-35 M 37 37 - - - - - - 15-37+ M 37 - 37 - - - - - 15-97 I 12 - - - 8 4 - - 17-6 I 6 - - - - - 6 - 17-8 II 8 - - - - 8 - - 17-26 I 26 - - - 26 - - - 17-35 M 55 55 - - - - - - 17-55+ M 55 - 55 - - - - - 17-99 I 23 - - - 21 2 - - 19-11 II 11 - - - - 11 - - 19-28 I 28 - - - 26 2 - - 19-30 I 30 - - - 29 1 - - 19-32 I 32 - - - 32 - - - 19-35 M 66 66 - - - - - - 19-66+ M 66 - 66 - - - - - 21-1+ M 79 - 79 - - - - - 21-11 I 11 - - - - - 11 - 21-16 II 16 - - - - 16 - - 21-35 M 79 79 - - - - - - 21-39 I 39 - - - 37 2 - - 21-41 I 41 - - - 41 - - - 21-75 M** 4 - - - - - - 4** 23-1+ M 100 - 100 - - - - - 23-2+ M 85 - - 85 - - - - 23-21 II 21 - - - - 21 - - 23-32 I 6 - 6 - - - - - 23-35 M 100 - 100 - - - - - 23-53 I 53 - - - 53 - - - 23-55 I 55 - - - 55 - - - 25-1+ M 128 - 128 - - - - - 25-2+ M 100 - - 100 - - - - 25-4 I 56 - - - 48 8 - - 25-19 I 19 - - - - - 19 - 25-24 I 24 - - - - 12 12 - 25-29 I 29 - - - - - 29 - 25-35 M 128 - 128 - - - - - 25-37 I 37 - - - - - 37 - 25-43 I 43 - - - 23 20 - - 25-49 I* 46 - - - 40 4 - 2* 25-8 CO-AX* 8 - - - - - - 8*** 25-20 N** 30 - - - 10 13 4* 3** 25-42 I, CO-AX 42 - - - 38 - - 4* 25-61 I 61 - - - 61 - - - 25-64 I 64 40 - - 8 10 6 - 25-66 I 66 53 - - 2 11 - - When choosing layout: First number = Step 3A - Shell Size Dash = Step 4 - Plating Second Number = 3B - Layout

+ = Inactive for new designs

S = Socket only * = Co-ax ** = Twinax *** = CO-AX/Twinax NOTE: Coaxial type contacts are only rated for 175°C (347°F). Read Less LAYOUTS BY NUMBER OF CONTACTS

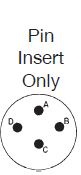

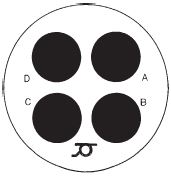

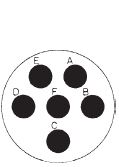

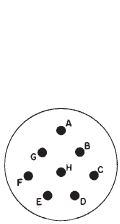

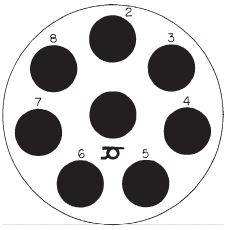

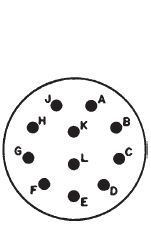

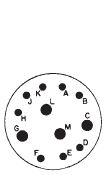

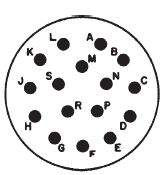

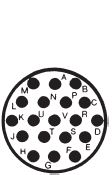

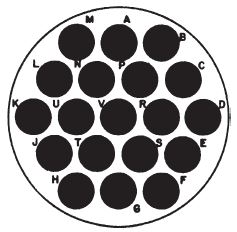

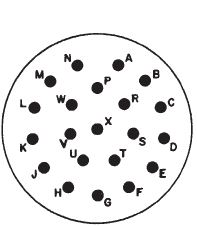

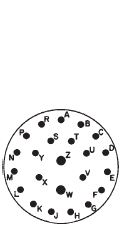

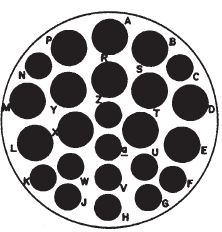

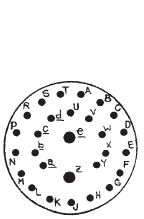

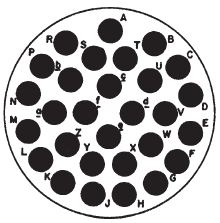

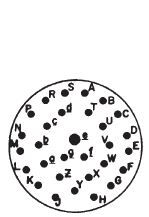

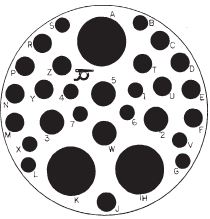

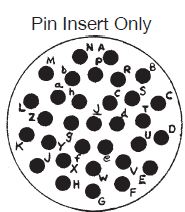

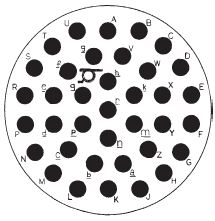

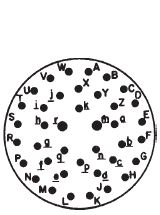

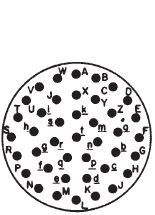

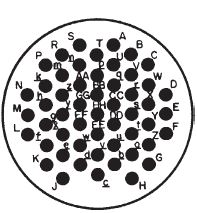

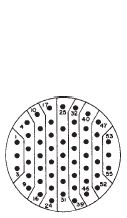

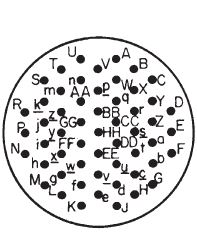

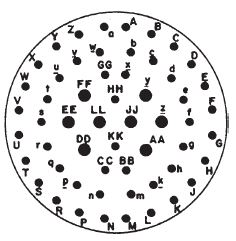

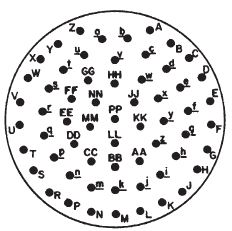

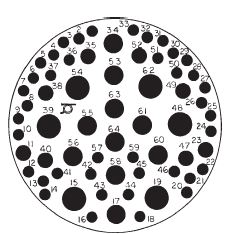

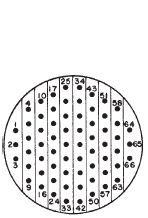

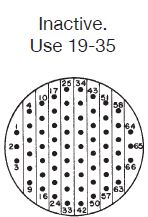

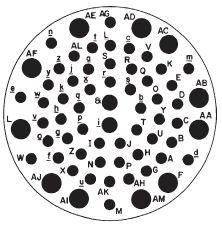

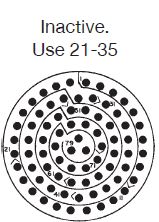

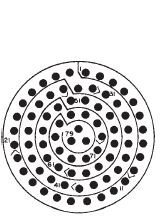

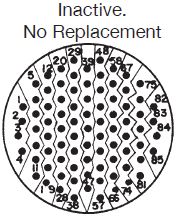

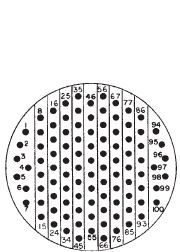

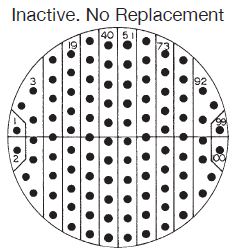

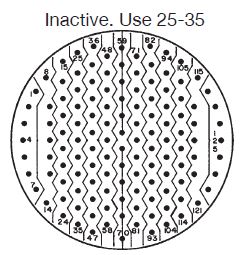

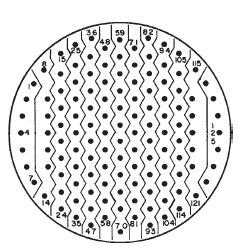

Drawing not to scale; mating-face view of pin insert shown (socket view is opposite). Contacts 3 4 5 6

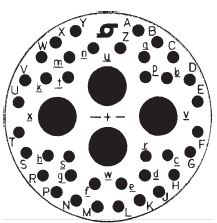

Layout 9-98 11-4 13-4 21-75 11-5 15-5 9-6 9-35 11-98 17-6 # of Contacts 3-#20 4-#20 4-#16 4-#8 5-#20 5-#16 6-#22M 6-#22D 6-#20 6-#12 Service Rating I I I M** I II M M I I Contacts 7 8 10 11

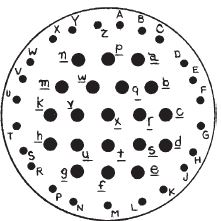

Layout 11-99 13-8 17-8 25-8 13-98 19-11 21-11 # of Contacts 7-#20 8-#20 8-#16 8-#8 10-#20 11-#16 11-#12 Service Rating I I II CO-AX*** I II I Contacts 12 13 15 16 18 19

Shell Size/Layout 15-97 11-13 11-35 15-15 21-16 15-18 15-19 # of Contacts 8-#20; 4-#16 13-#22M 13-#22D 14-#20; 1-#16 16-#16 18-#20 19-#20 Service Rating I M M I II I I Contacts 19 21 22 23 24

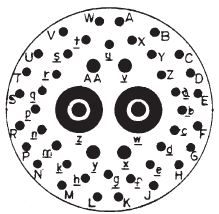

Layout 25-19 23-21 13-22 13-35 17-99 25-24 # of Contacts 19-#12 21-#16 22-#22M 22-#22D 21-#22; 2-#16 12-#16 12#12 Service Rating I II M M I I Contacts 26 28 29 30 32

Layout 17-26 19-28 25-29 19-30 25-20 19-32 # of Contacts 26-#20 26-#20; 2-#16 29-#16 29-#20; 1-#16 10-#20; 13-#16; 14-#12*; 3-#8** 32-#20 Service Rating I I I I N I Contacts 32 37 39 41

Layout 23-32 15-35 15-37 25-37 21-39 21-41 # of Contacts 32-#20 37-#22D 37-#22M 37-#16 37-#20; 2-#16 41-#20 Service Rating I M M I I I Contacts 42 43 46 53 55

Layout 25-42 25-43 25-46 23-53 17-35 # of Contacts 38-#20; 4-#8* 23-#20 20-#16 40-#20; 4-#16; 2-#8* 53-#20 55-#22D Service Rating I, CO-AX I I I M Contacts 55 56 61 64

Layout 17-55 23-55 25-4 25-61 25-64 # of Contacts 55-#22M 55-#20 48-#20; 8-#16 61-#20 40-#22D; 8-#20; 10-#16; 6-#12; M Service Rating M I I I M Contacts 66 79 85

Layout 19-35 19-66 25-66 21-1 21-35 23-2 # of Contacts 66-#22D 66-#22M 55-#22D; 2-#20; 11-#16 79-#22M 79-#22D 85-#22 Service Rating M M I M M M Contacts 100 128

Layout 23-1 23-35 25-2 25-1 25-35 # of Contacts 100-#22D 100-#22D 100-#22 128-#22M 128-#22D Service Rating M M M M M *Co-ax **Twinax ***Co-ax/Twinax NOTE: Coaxial type contacts are only rated for 175°C (347°F). Contact us for more information. Read Less STEP 4: PLATINGSTEP 4: CHOOSE PLATING Military Commercial B B Olive Drab Chromate over Cadmium over Electroless Nickel -65°C to 175°C F N Electroless Nickel -65°C to 200°C (-85°F to 392°F) A A Clear Chromate over Cadmium over Electroless Nickel -65°C to 150°C (inactive) STEP 5: CONTACTSTEP 5: CHOOSE CONTACT

See step 6 if you are not ordering contacts with part

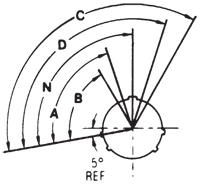

P = Pin A = Less Pin Contacts STEP 6: POLARIZATIONSTEP 6: CHOOSE POLARIZATION

N = Normal Standard (omit on Military part number) B = Limited Availability Shell Size N A B C D 9 95 77 - - 113 11 95 81 67 123 109 13 95 75 63 127 115 15 95 74 61 129 116 17 95 77 65 125 113 19 95 77 65 113 240 21 95 77 65 113 240 23 95 80 69 121 110 25 95 80 69 121 110

STEP 7: MODIFIERSTEP 7: CHOOSE MODIFIER

-LC = For use with standard contacts, but supplied without contacts, seal plugs or tools Note: -LC is not marked on part

|

|

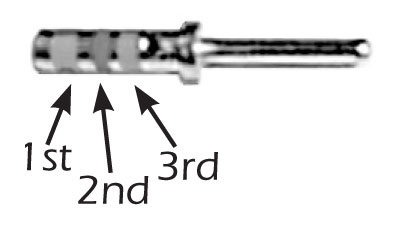

CONTACTSITT CANNON KJL SERIES CONTACTS - PINS

Contact Size Wire Size AWG Pin Contact Color Bands Color Bands Color Bands Wire Strip Lengths Wire Range Min. Wire Range Max. Wire Hole Filler Color 22D 28,26, M39029/58-360 Orange Blue Black .125 (3.18) .030 (0.76) .054 (1.37) MS27488-22-2 Black *22M 28,26 M39029/58-361 Orange Blue Brown .125 (3.18) .030 (0.76) .050 (1.27) MS27488-22-2 Black *22 26,24 M39029/58-362 Orange Blue Red .125 (3.18) .034 (0.86) .060 (1.52) MS27488-22-2 Black 20 20,22 M39029/58-363 Orange Blue Orange .188 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16,18 M39029/58-364 Orange Blue Yellow .188 (4.77) .065 (1.65) .109 (2.77) MS27488-16-2 Blue 12 12&14 M39029/58-365 Orange Blue Green .188 (4.77) .097 (2.46) .142 (3.61) MS27488-12-2 Yellow 8 Co-ax+ - - - - - .135 (3.43) .155 (3.94) MS27488-8-3 - + For Printed Circuit, Co-ax, Fiber Optic (MIL-T-29504/4 for size 16 contacts) or Thermocouple Contacts, contact us. ITT CANNON KJL SERIES CONTACTS - SOCKETS

Contact Size Wire Size AWG Socket Contact Color Bands Color Bands Color Bands Wire Strip Lengths Wire Range Min. Wire Range Max. Wire Hole Filler Color 22D 22,26, M39029/56-348 Orange Yellow Gray .125 (3.18) .030 (0.76) .054 (1.37) MS27488-22-2 Black 20 20,22 M39029/56-351 Orange Green Brown .188 (4.77) .040 (1.02) .083 (2.11) MS27488-20-2 Red 16 16,18 M39029/56-352 Orange Green Red .188 (4.77) .065 (1.65) .109 (2.77) MS27488-16-2 Blue 12 12&14 M39029/56-353 Orange Green Orange .188 (4.77) .097 (2.46) .142 (3.61) MS27488-12-2 Yellow 8 Co-ax+ - - - - - .135 (3.43) .155 (3.94) MS27488-8-3 - Contact Color Codes 0 Black 1 Brown 2 Red 3 Orange 4 Yellow 5 Green 6 Blue 7 Violet 8 Gray 9 White + For Printed Circuit, Co-ax, Fiber Optic (MIL-T-29504/5 for size 16 contacts) or Thermocouple Contacts, contact us. * Contact us for more information. All dimensions in inches (millimeters in parentheses) unless otherwise stated. CONTACT TOOLSITT CANNON KJL SERIES CONTACT TOOLS - PINS

Contact Size Hand Crimp Tool Power Crimp Tool Turret Heads Use Locator Color Plastic Insertion/ Extraction Tool Insertion Tip Color Extraction Tip Color Metal Insertion Tool Color Band Metal Extraction Tool Color Band Color Band 22D M22520/ CBT565 M22520/ - M81969/ Green White MS27495 Black MS27495 Black White 22M M22520/ CBT565 M22520/ - M81969/ Green White MS27495 Black MS27495 Black White 22 M22520/ CBT565 M22520/ - M81969/ Green White MS27495 Black MS27495 Black White 20 M22520/ CBT530 M22520/ Red M81969/ Red Orange MS27495 Red MS27495 Red White 16 M22520/ CBT530 M22520/ Blue M81969/ Blue White MS27495 Blue MS27495 Blue White 12 M22520/ CBT530 M22520/ Yellow M81969/ Yellow White DAK95- - DRK95- - - 8 - - - - - - - - - - - - ITT CANNON KJL SERIES CONTACT TOOLS - SOCKETS

Contact Size Hand Crimp Tool Power Crimp Tool Turret Heads Use Locator Color Plastic Insertion/ Extraction Tool Insertion Tip Color Extraction Tip Color Metal Insertion Tool Color Band Metal Extraction Tool Color Band Color Band 22D M22520/ CBT565 M22520/ - M81969/ Green White MS27495 Black MS27495 Black White 20 M22520/ CBT530 M22520/ Red M81969/ Red Orange MS27495 Red MS27495 Red White 16 M22520/ CBT530 M22520/ Blue M81969/ Blue White MS27495 Blue MS27495 Blue White 12 M22520/ CBT530 M22520/ Yellow M81969/ Yellow White DAK95-12B - DRK95-12B - - 8 - - - - - - - - - - - - ITT CANNON KJL SERIES D38999-22 TOOL KIT / D38999-20 TOOL KIT CONTAINS:

|

|

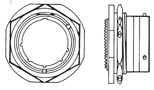

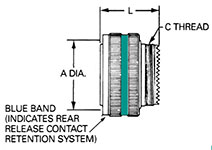

PLUGSITT CANNON KJL SERIES PLUGS MS27467/KJL6

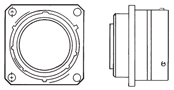

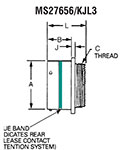

L Max. Overall Length Shell Size A Dia. Max. G Dia. Max. T Class P Class C Rear Thread 9 .585 (14.86) .859 (21.82) 1.234 (31.34) 1.671 (42.44) 7/16-28 11 .717 (18.21) .984 (24.99) 1.234 (31.34) 1.671 (42.44) 9/16-24 13 .866 (22.00) 1.156 (29.36) 1.234 (31.34) 1.671 (42.44) 11/16-24 15 .990 (25.15) 1.281 (32.54) 1.234 (31.34) 1.671 (42.44) 13/16-20 17 1.115 (28.32) 1.406 (35.71) 1.234 (31.34) 1.671 (42.44) 15/16-20 19 1.222 (31.04) 1.516 (38.51) 1.234 (31.34) 1.671 (42.44) 1-1/16-18 21 1.347 (34.21) 1.641 (41.68) 1.234 (31.34) 1.766 (44.86) 1-3/16-18 23 1.472 (37.39) 1.766 (44.86) 1.234 (31.34) 1.766 (44.86) 1-5/16-18 25 1.597 (40.56) 1.891 (48.03) 1.234 (31.34) 1.766 (44.86) 1-7/16-18 All dimensions are shown in inches (millimeters in parentheses). RECEPTACLESITT CANNON KJL SERIES RECEPTACLES

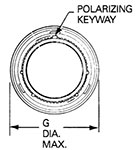

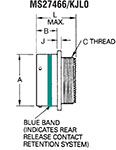

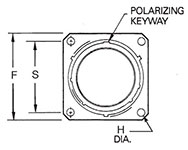

NOTE: K = .219 (5.56) for sizes 9-19 and .250 (6.35) for sizes 21-25 L Max. Overall Length B Max. Shell A Dia. Max. MS27466/ MS27656/ MS27505/ MS27466 KJL3 C Rear Thread UNEF-2A KJL0 KJL3 J Max. F Max. S (T.P.) H Max. 9 0.573 (14.55) 1.240 (31.5) 1.247 (31.67) 1.099 (27.91) 0.632 (16.05) 0.820 (20.83) 7/16-28 .100 (2.54) .958 (24.33) .719 (18.26) 0.138 (3.51) 11 0.701 (17.81) 1.240 (31.5) 1.247 (31.67) 1.099 (27.91) 0.632 (16.05) 0.820 (20.83) 9/16-24 .100 (2.54) 1.051 (26.70) .812 (20.62) 0.138 (3.51) 13 0.851 (21.62) 1.240 (31.5) 1.247 (31.67) 1.099 (27.91) 0.632 (16.05) 0.820 (20.83) 11/16-24 .100 (2.54) 1.145 (29.08) .906 (23.01) 0.138 (3.51) 15 0.976 (24.79) 1.240 (31.5) 1.247 (31.67) 1.099 (27.91) 0.632 (16.05) 0.820 (20.83) 13/16-20 .100 (2.54) 1.239 (26.70) .969 (24.61) 0.138 (3.51) 17 1.101 (27.97) 1.240 (31.5) 1.247 (31.67) 1.099 (27.91) 0.632 (16.05) 0.820 (20.83) 15/16-20 .100 (2.54) 1.332 (33.83) 1.062 (26.97) 0.138 (3.51) 19 1.208 (30.68) 1.240 (31.5) 1.247 (31.67) 1.099 (27.91) 0.632 (16.05) 0.820 (20.83) 1-1/16-18 .100 (2.54) 1.458 (37.03) 1.156 (29.36) 0.138 (3.51) 21 1.333 (33.86) 1.240 (31.5) 1.247 (31.67) 1.100 (27.94) 0.602 (15.29) 0.790 (20.07) 1-3/16-18 .130 (3.30) 1.582 (40.18) 1.250 (31.75) 0.138 (3.51) 23 1.458 (37.03) 1.240 (31.5) 1.247 (31.67) 1.100 (27.94) 0.602 (15.29) 0.790 (20.07) 1-5/16-18 .130 (3.30) 1.708 (43.38) 1.375 (34.93) 0.157 (3.99) 25 1.583 (40.21) 1.240 (31.5) 1.247 (31.67) 1.100 (27.94) 0.602 (15.29) 0.790 (20.07) 1-7/16-18 .130 (3.30) 1.832 (46.53) 1.500 (38.10) 0.157 (3.99) ++ Most Popular ** Least Popular

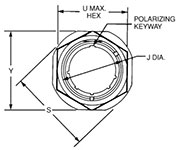

Overall Length Shell A Dia. Max. D Dia. Max. H Max. Class T Class P U Max. Jam Nut Flats S Max. Y Max. J Max. V Jam Nut Thread C Rear Thread UNEF 2A 9 .573 (14.55) .655 (16.64) .120 (3.05) 1.358 (34.50) 1.451 (36.86) .892 (22.66) 1.204 (30.58) 1.062 (26.97) .662 (16.81) 11/16-24UNEF 7/16-28 11 .701 (17.81) .755 (19.18) .120 (3.05) 1.358 (34.50) 1.451 (36.86) 1.017 (25.83) 1.391 (35.33) 1.250 (31.75) .810 (20.57) 13/16-24UNEF 9/16-24 13 .851 (21.62) .942 (23.93) .120 (3.05) 1.358 (34.50) 1.451 (36.86) 1.205 (30.61) 1.516 (38.51) 1.375 (34.93) .960 (24.38) 1-20UNEF 11/16-24 15 .976 (24.79) 1.066 (27.08) .120 (3.05) 1.358 (34.50) 1.451 (36.86) 1.329 (33.76) 1.641 (41.68) 1.500 (38.10) 1.085 (27.56) 1-1/8-18UNEF 13/16-20 17 1.101 (27.97) 1.191 (30.25) .120 (3.05) 1.358 (34.50) 1.451 (36.86) 1.455 (39.96) 1.766 (44.86) 1.625 (41.28) 1.210 (30.73) 1-1/4-18UNEF 15/16-20 19 1.208 (30.68) 1.316 (33.43) .151 (3.84) 1.358 (34.50) 1.451 (36.86) 1.579 (40.11) 1.954 (49.63) 1.812 (46.02) 1.317 (33.45) 1-3/8-18UNEF 1-1/16-18 21 1.333 (33.86) 1.441 (36.60) .151 (3.84) 1.358 (34.50) 1.451 (36.86) 1.705 (43.31) 2.078 (52.37) 1.938 (49.23) 1.442 (36.63) 1-1/2-18UNEF 1-3/16-18 23 1.458 (37.03) 1.566 (39.78) .151 (3.84) 1.358 (34.50) 1.451 (36.86) 1.829 (46.46) 2.204 (55.98) 2.062 (52.37) 1.567 (39.80) 1-5/8-18UNEF 1-5/16-18 25 1.583 (40.21) 1.691 (42.95) .151 (3.84) 1.358 (34.50) 1.451 (36.86) 2.017 (51.23) 2.328 (59.13) 2.188 (55.58) 1.692 (42.98) 1-3/4-18UNS 1-7/16-18 Specifications subject to change All dimensions are shown in inches (millimeters in parentheses). KJL FLANGED PANEL CUTOUTSITT CANNON KJL SERIES KJL FLANGED PANEL CUTOUTS

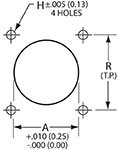

Shell A Diameter H Dia. R (T.P.) Screw 9 .665 (16.89) .125 (3.18) .719 (18.26) #4 11 .812 (20.62) .125 (3.18) .812 (20.62) #4 13 .965 (24.51) .125 (3.18) .906 (23.01) #4 15 1.085 (27.55) .125 (3.18) .969 (24.61) #4 17 1.210 (30.73) .125 (3.18) 1.062 (26.97) #4 19 1.322 (33.57) .125 (3.18) 1.156 (29.36) #4 21 1.447 (36.75) .125 (3.18) 1.250 (31.75) #4 23 1.569 (39.85) .152 (3.86) 1.375 (34.93) #6 25 1.703 (43.25) .152 (3.86) 1.500 (38.10) #6 All dimensions are shown in inches (millimeters in parentheses). KJL JAM NUT PANEL CUTOUTSITT CANNON KJL SERIES KJL JAM NUT PANEL CUTOUTS

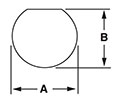

Shell Size A Diameter +.10-.000 (+.25-.00) B Diameter +.10-.000 (+.25-.00) 9 .693 (17.60) .657 (16.70) 11 .825 (20.96) .770 (19.59) 13 1.010 (25.65) .955 (24.26) 15 1.135 (28.83) 1.085 (27.56) 17 1.260 (32.00) 1.210 (30.73) 19 1.385 (35.18) 1.335 (33.91) 21 1.510 (38.35) 1.460 (37.08) 23 1.635 (41.53) 1.585 (40.26) 25 1.760 (44.70) 1.710 (43.43) All dimensions are shown in inches (millimeters in parentheses). PANEL THICKNESSITT CANNON KJL SERIES PANEL THICKNESS

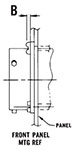

MS27466/KJL0 Front Panel Mount (not recommended for rear mounting)

Size B Max Panel and Screw Head 9 .234 (5.94) 11 .234 (5.94) 13 .234 (5.94) 15 .234 (5.94) 17 .234 (5.94) 19 .234 (5.94) 21 .204 (5.18) 23 .204 (5.18) 25 .193 (4.90) MS27656/KJL3 MS27505E/KJLE Rear Panel Mount (including hardware)

Size B Max Panel and Screw Head 9 min .062 (1.57) / max .125 (3.18) 11 min .062 (1.57) / max .125 (3.18) 13 min .062 (1.57) / max .125 (3.18) 15 min .062 (1.57) / max .125 (3.18) 17 min .062 (1.57) / max .125 (3.18) 19 min .062 (1.57) / max .125 (3.18) 21 min .062 (1.57) / max .125 (3.18) 23 min .062 (1.57) / max .125 (3.18) 25 min .062 (1.57) / max .125 (3.18) |

|

ITT CANNON KJL SERIES ACCESSORIES

Receptacle Dust Caps KJL Dummy Receptacles For Flanged For Jam Nut Plug Cap 9 M38999/9-9B MS27502**9C MS27502**9N MS27501**9C 11 M38999/9-11B MS27502**11C MS27502**11N MS27501**11C 13 M38999/9-13B MS27502**13C MS27502**13N MS27501**13C 15 M38999/9-15B MS27502**15C MS27502**15N MS27501**15C 17 M38999/9-17B MS27502**17C MS27502**17N MS27501**17C 19 M38999/9-19B MS27502**19C MS27502**19N MS27501**19C 21 M38999/9-21B MS27502**21C MS27502**21N MS27501**21C 23 M38999/9-23B MS27502**23C MS27502**23N MS27501**23C 25 M38999/9-25B MS27502**25C MS27502**25N MS27501**25C ** Select code for plating: B = Olive Drab Chromate over Cadmium over Nickel (500 Hour Salt Spray) F = Electroless Nickel (Fluid Resistant) A = Gold Iridite over Cadmium Nickel C = Hard Anodize

Endbells Cable Range KJL Straight, Low Cost Right-Angle, Low Cost Min. Max. 9 M85049/49-2-8** M85049/47-**8 .098 (2.49) .234 (5.94) 11 M85049/49-2-10** M85049/47-**10 .153 (3.89) .234 (5.94) 13 M85049/49-2-12** M85049/47-**12 .190 (4.83) .328 (8.33) 15 M85049/49-2-14** M85049/47-**14 .260 (6.60) .457 (11.61) 17 M85049/49-2-18** M85049/47-**18 .325 (8.25) .614 (15.60) 19 M85049/49-2-18** M85049/47-**18 .325 (8.25) .614 (15.60) 21 M85049/49-2-20** M85049/47-**20 .343 (8.71) .698 (17.73) 23 M85049/49-2-22** M85049/47-**22 .391 (9.68) .823 (20.90) 25 M85049/49-2-24** M85049/47-**24 .418 (10.6) .853 (21.67) ** Select code for connector plating: W = Olive Drab Chromate over Cadmium over Nickel (1000 Hour Salt Spray) N = Electroless Nickel (Fluid Resistant) A = Black Anodize

Shell Size Self-Locking Endbells Clamp Range KJL Straight Right-Angle Min. Max. 9 M85049/49-2#8** M85049/47#**8 .098 (2.49) .234 (5.94) 11 M85049/49-2#10** M85049/47#**10 .153 (3.89) .234 (5.94) 13 M85049/49-2#12** M85049/47#**12 .190 (4.83) .328 (8.33) 15 M85049/49-2#14** M85049/47#**14 .260 (6.60) .457 (11.61) 17 M85049/49-2#16** M85049/47#**16 .283 (7.19) .614 (15.60) 19 M85049/49-2#18** M85049/47#**18 .325 (8.25) .634 (16.10) 21 M85049/49-2#20** M85049/47#**20 .343 (8.71) .698 (17.73) 23 M85049/49-2#22** M85049/47#**22 .391 (9.68) .823 (20.90) 25 M85049/49-2#24** M85049/47#**24 .418 (10.62) .853 (21.67) # Add S for Self-Locking: S = Self-Locking with Detent ** Select code for connector plating: W = Olive Drab Chromate over Cadmium over Nickel (1000 Hour Salt Spray) N = Electroless Nickel (Fluid Resistant) S = 300 Series Steel, Passivated Sealed EMI/RFI Orientation Endbell Description M85049/62 Y N S Heat Shrink Boot Adapters Designed for use with straight or right-angle shrink boots. A knurled rear section with a boot groove provide an excellent surface for the boot to grab the metal endbell. Available with lock wire and drain holes. M85049/32 N N S Extender Backshell Non-environmental designed for use with jacketed cable allow extra space to break out the wires and still provide stain relief clamping to the outside of the cable jacket. M85049/17 Y Y S Extender Backshell This EMI/RFI shielding environmentally sealing endbell features a standard style cable clamp with gland seal at the end of an extender style backshell. M85049/29 N Y S Extender Backshell This EMI/RFI-shielding, non-environmentally-sealing endbell features a standard style cable clamp. Banding Y Y S Banding Adapter Banding adapters utilize a band of metal that fastens and grounds cable shields to the outside of endbells. This method of terminating shields has advantages in that they typically use tools to tighten and trim the bands. These tools make the termination tight, repeatable, reworkable (if you make a mistake, just cut the band off and start again) and facilitates service. Banding adapters help lower the total applied cost by having simpler designs that have fewer parts with uncomplicated assembly procedures. Custom S Custom Designs If the Military Standard endbells don’t fit your needs, contact us and we will customize an endbell solution to fit you. Most of these customized endbells are typically assembled in 4-8 weeks or sooner! M85049/27 N N S E Nut Wire seal compression nut All dimensions shown in inches (millimeters in parentheses) Specifications subject to change. |

|

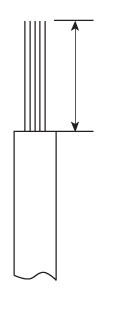

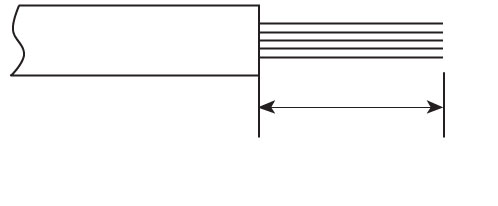

WIRE STRIPPINGITT CANNON KJL SERIES WIRE STRIPPING

Strip insulation from end of wire to be crimped. (See table for proper stripping dimensions.) Do not cut or damage wire strands.

Wire Size A 22, 22m, 22D .125 (3.18) 20 .188 (4.77) 16 .188 (4.77) 12 .188 (4.77) CONTACT CRIMPINGITT CANNON KJL SERIES CONTACT CRIMPING

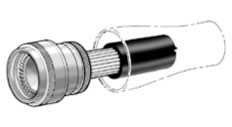

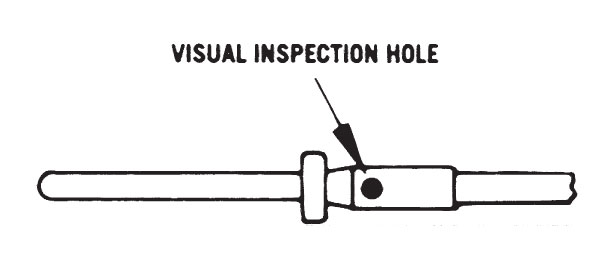

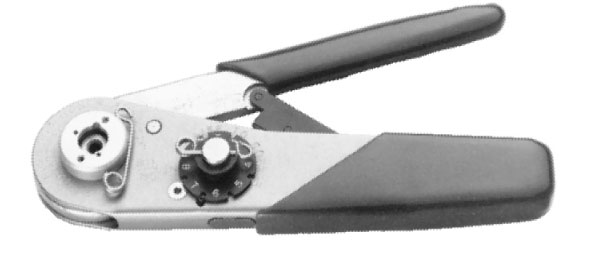

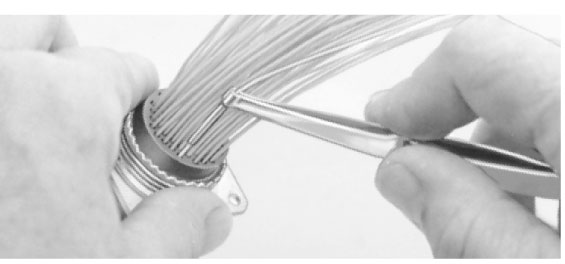

Step 1: Insert stripped wire into contact crimp pot. Wire must be visible through inspection hole. Step 2: Using correct crimp tool and locator, cycle the tool once to be sure the indentors are open. Insert contact and wire into locator. Squeeze tool handles firmly and completely to ensure a proper crimp. The tool will not release unless the crimp indentors in the tool head have been fully actuated. Step 3: Release crimped contact and wire from tool. Be certain the wire if visible through inspection hole in contact. CONTACT INSERTIONITT CANNON KJL SERIES CONTACT INSERTION

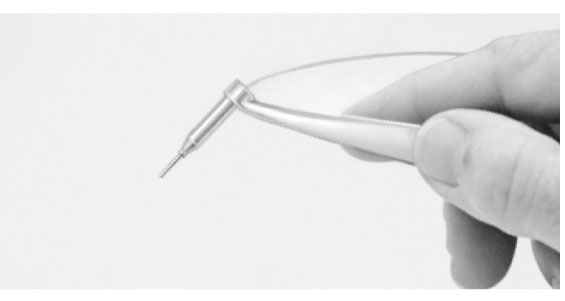

Step 1: Remove hardware from plug or receptacle and slip over wire bundle in proper order for reassembly. Step 2: Using proper plastic or metal insertion tool for corresponding contact, position wire in tip of the tool so that the tool tip presses against the contact shoulder.

Step 3: Press tool against contact shoulder and, with firm and even pressure, insert wired contact and tool tip into center contact cavity. A slight “click” may be heard as metal retaining tines snap into place behind contact shoulder. Step 4: Remove tool and pull back lightly on wire to make sure contact is properly seated. Repeat operation with remainder of contacts to be inserted, beginning with the center cavity and working outward in alternating rows. Step 5: After all contacts are inserted, fill any empty cavities with wire sealing plugs. Reassemble plug or receptacle hardware. Crimp Kits D38999-22 Tool Kit D38999-20 Tool Kit CONTACT EXTRACTIONITT CANNON KJL SERIES CONTACT EXTRACTION

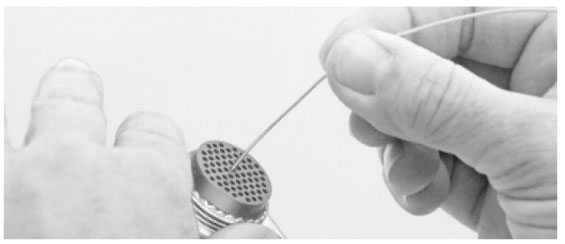

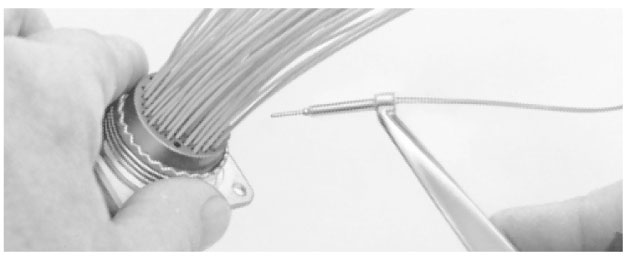

Step 1: Remove hardware from plug or receptacle and slide hardware back along wire bundle. Step 2: Using plastic or metal extraction tool with proper color code corresponding to contact size, place wire in tool.

Step 3: Insert tool into contact cavity until tool tip bottoms against the contact shoulder, expanding clip retaining tines. Step 4: Hold wire firmly in tool and extract wired contact and tool. Repeat operation for all contacts to be extracted. Step 5: Fill any empty cavities with wire sealing plugs. Reassemble plug or receptacle hardware. NOTE: KJ Series shown |

Philadelphia

19116

Click here for the contact information of the branch nearest you.