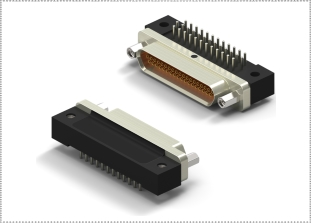

Ulti-Mate Micro-D Right Angle Connector .075 X .075 Styles 9/19

CONDENSED FOOTPRINT RIGHT ANGLE MICRO-D CONNECTOR

PEI-Genesis offers Ulti-Mate’s Micro-D Circuit Series - Right Angle Connector .075 x .075 Style 9 offers a condensed footprint that is designed to fit circuit board applications; Style 19 is designed for flex circuit applications where the use of a jackscrew is necessary. Both utilize the same condensed footprint and are recommended for drop-in replacement for the MR75 series industry standard. Spacing between rows is 0.075 on all layouts. Stamped pins create consistency when assembled in order of manufacture, assuring dimensional consistency and quality control. Built to MIL-DTL-83513 specifications, the Ulti-Mate Micro-D Circuit Series Right Angle Connector is proven reliable under tough operating conditions.

|

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 MATERIALS & FINISHES

Pin Contacts Beryllium Copper (C17200) per ASTM B194.

Socket Contacts Copper alloy (C21000) per ASTM B36 or leaded commercial bronze (C314000) per ASTM B140.

Contact Plating Gold plated per MIL-DTL-45204D. 50 microinches min. is the standard thickness.

Metal Shells Aluminum alloy per SAE-AMS-QQ-A-200/8, type 6061-T6. Finish is cadmium per SAE-AMS-QQ-P-416, TYPE II, CLASS 3, with suitable underplate with yellow chromate, this plating is not RoHS compliant. Or Finish Electroless Nickel plate per SAE AMS2404, class 3 or 4, .0005 minimum thickness.

Insulator Material Preferred material is Polyphenylene sulfide (PPS) per MIL-M-24519 or ASTM D5927 GST 40F. Color Black.

LCP Liquid Crystal Polymer-Vectra 130 (optional).

Interfacial Seals Fluorosilicone elastomer per MIL-R-25988. Standard on “M” Series socket face.

Hardware Stainless Steel, passivated.

Standard Plating Electroless Nickel or Cadmium.

Optional Plating Tin, Olive Drab or Gold.

Stainless Steel shells are available in all configurations.

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 ELECTRICAL DATA

Contact Resistance 8 mΩ Maximum @ 2.5 A

Current Rating 3.0 A Maximum

Dielectric Withstanding Voltage 900 VAC at sea level, 300 VAC @ 70,000 ft. Solder cups and shielded cable same as MIL-DTL-83513; 600 VAC at sea level 150VAC @ 70,000 ft.

Insulation Resistance 5,000 MΩ Minimum

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 MECHANICAL

Contact Engaging and Separating Forces 6 oz. max per MIL-DTL-83513 (contact average is 3 oz.); Separation force is 5.0 oz. minimum.

Contact Mating and Unmating Forces per MIL-DTL-83513 Mate = 10 oz. X number of contacts maximum. Unmate = 10.5 oz. X number of contacts minimum.

Vibration Mate = 10 oz. X number of contacts maximum. Unmate = 10.5 oz. X number of contacts minimum.

Shock No damage or interruption detected (one microsecond sensitivity) when subjected to Test Condition E. Method 2004 of MIL-STD-1344.

Durability No mechanical defects after 500 matings; Test criteria are mating force, contact resistance, contact engagement, and separation forces.

Salt Spray No exposure of base metal or loss of performance after 96 hours for both Nickel and Cadmium plating.

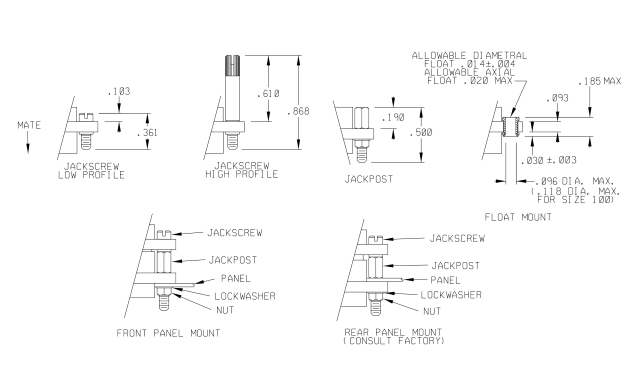

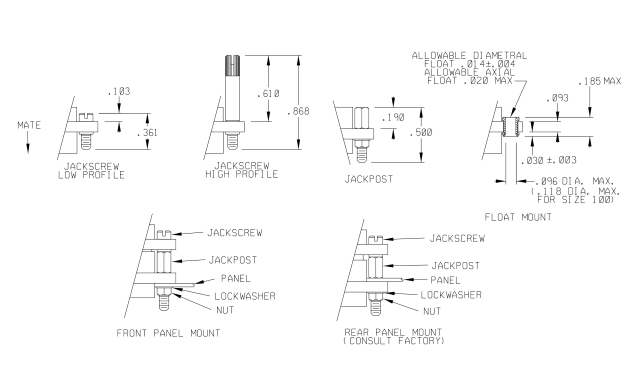

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 HARDWARE

Jackscrew Lo Allen Jackscrew Hi Allen Jackscrew

Lo Slot Jackscrew

Hi Slot Jackpost

M83513/05-02

M83513/05-03

M83513/05-05

M83513/05-06

M83513/05-07

83041xxxx

83041xxxx

83041xxxx

83041xxxx

83041xxxx

.361

(9.17) .868

(22.05) .361

(9.17) .868

(22.05) .500

(12.70) .103

(2.62) .610

(15.49) .103

(2.62) .610

(15.49) .190

(4.83) 2-56 UNC-2A

2-56 UNC-2A

2-56 UNC-2A

2-56 UNC-2A

2-56 UNC-2B

Jackscrew Lo Allen Jackscrew Hi Allen Jackscrew

Lo Slot Jackscrew

Hi Slot Jackpost

M83513/05-012

M83513/05-013

M83513/05-015

M83513/05-016

M83513/05-017

83041xxxx

83041xxxx

83041xxxx

83041xxxx

83041xxxx

.390

(9.91) .902

(22.91) .390

(9.91) .902

(22.91) .500

(12.70) .103

(2.62) .610

(15.49) .103

(2.62) .610

(15.49) .185

(4.70) 4-40 UNC-2A

4-40 UNC-2A

4-40 UNC-2A

4-40 UNC-2A

4-40 UNC-2B

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 CONTACT ARRANGMENTS

Custom 2 row arrangements

Available in rugged metal & intermatable rugged plastic shell configurations or available in low profile Metal & intermatable low profile plastic shell configurations.

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 TERMINATIONS

Available Terminations Pre-wired solid wire 24, 25 AWG Tin

Solder dipped or gold plated in standard and custom lead lengths

ULTI-MATE MICRO-D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 MOUNT TYPE

Right angle or vertical mount. PC board or Flex circuit applications

|

|

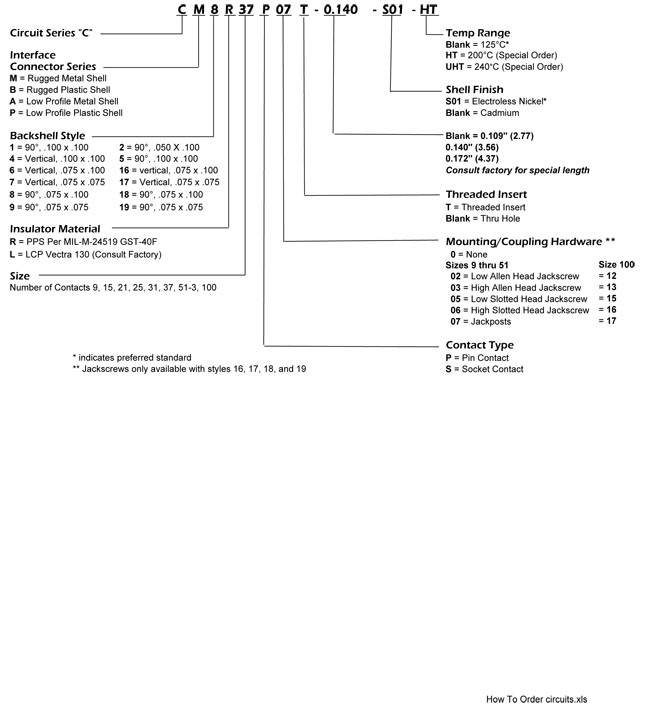

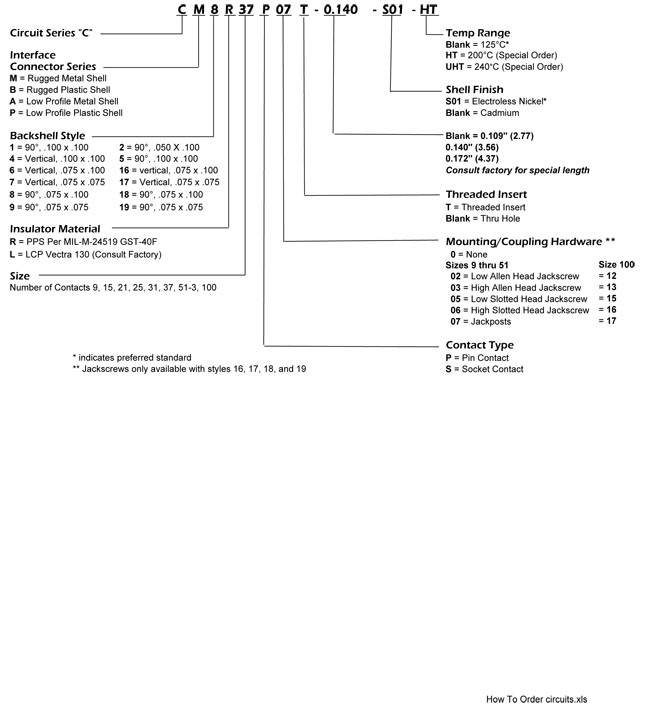

ULTI-MATE MICRO D CIRCUIT RIGHT ANGLE .075 x .075 STYLE 9, 19 CREATE PART NUMBER

|