ITT Cannon SLC Connectors | Snap Lock Circular

HARSH-ENVIRONMENT SNAP LOCK CONNECTORS

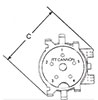

The ITT Cannon Snap Lock Environmental series (SLC) is an environmentally-sealed, circular connector created for printed circuit board (PCB), cable-to-cable or bulkhead applications. The SLC connector series is environmentally-sealed against sand and dust and are designed for use under-the-hood, withstanding harsh off-road contaminants including oil and antifreeze. This SLC connector series is user-friendly and easy to assemble, with an audible and tactile feedback. SLC connector contacts will handle up to 5 amps continuous at a fully-rated temperature range of -40°C to +125°C. The SLC connector series is available as a 5 pin connector and a 10 pin connector. For full details on ITT Cannon SLC connector series snap lock connectors, see the product specifications below.

|

FEATURESITT CANNON SLC SERIES FEATURES

MATERIALS & FINISHESITT CANNON SLC SERIES MATERIALS & FINISHES

Shell High-performance thermoplastic body, silicone wire seals

Contacts Copper alloy

Plating Selective gold over nickel plating on mating surface, tin/lead over nickel plating on wire crimp area

ELECTRICAL DATAITT CANNON SLC SERIES ELECTRICAL DATA

Dielectric Withstanding Voltage 1000 Vac rms at sea level

Current Rating 5 Amps continuous at 125ºC

Wire Range Sizes 20-16 AWG

Contact Resistance 10 milliohms maximum

Insulation Resistance 20 megohms minimum (USCAR)

MECHANICALITT CANNON SLC SERIES MECHANICAL

Operating Temperature -40°C to 125°C (-40°F to 257°F)

Sealing 2-12 inches of 5% salt solution for 24 hours

Wire Sealing Range .095”-.120” (2.42mm - 3.05mm)

Insulation Strip Length .210” - .220” (5.33mm - 5.59mm)

Mating Life 25 cycles minimum

Salt Spray 5% solution 96 hours

Heat 125°C +/- 3° 1000 hours

Chemical Resistance Resistant to most common automotive contaminants

Vibration 10.2 grms 20 hours minimum

Shock 100 g’s 18 shocks for 6 milliseconds

Contact Type Crimp using automatic, semi-automatic or hand tooling, printed circuit

Number of Circuits 5 to 10

Contact Insertion From rear with no insertion tool needed

Contact Removal From rear with low cost hand tool

Contact Retention 25 lbs. (111N) minimum

Polarization Keys and keyways

TEST PARAMETERSITT CANNON SLC SERIES TEST PARAMETERS

SLC Products are designed to meet Cannon specifications CS-206, CS-210 and CS-216. Items of most general interest to users are designers are listed below. Test Description Requirements

Environmental Sealing Sand and dust MIL-STD-202 method 110 Test Condition A

5% salt spray 96 hours 10 cycles of 24 hours, 90-98% humidity Steam Cleaning/Pressure Wash 95°C, 375 Cycles 750 PSIG Solvent Resistance/Immersion (see 3,2,3,9) Thermal Shock 100 Cycles -40°C to +150°C +/- 3°C Contact Crimp Tensile Strength The minimum tensile load required to separate the wire from the contact, either by pulling the wire out of the crimp joint or by joint or by breaking the wire within the crimp joint shall not be less than the applicable limits as specified. Wire breakage or contact damage not due to crimping at less than tensile loads shall not constitute a failure.

Wire Size AWG Crimp Tensile Strength, Pounds Minumum 16 35 18 25 20 20 Vibration Connectors shall be subjected to random vibration in accordance with MIL-STD-1344, Method 2005.1, test condition VI for 20 hours along each of the following three axes:

Direction Grms Radial Axis of connector (Y) 10.2 Longitudinal axis of connector (Z) 10.2 Electrical continuity of the connectors shall be monitored during the last 20 minutes sweep in each axis with a test current of 100 milliamps or less and a test voltage less than 2VDC. Electrical discontinuities in excess of 10 microseconds shall be cause of failure. Durability Connectors shall be subjected to 25 cycles of mating and unmating at room temperature. Following this test there shall be no evidence of damage to the contacts, contact plating, connector housing or seals which may prove detrimental to reliable performance of the connector.

Contact Contacts shall not be displaced greater than 0.030 inches from the connector body when a force of 10 pounds is applied. When this test follows maintenance again the same contacts shall be tested.

Maintenance Aging Consist of subjecting each wired receptacle to 5 cycles of removal and reinsertion of 20% of the contacts or a minimum of 5 per connector with approved tooling.

Mating and Separating Force The maximum force required to mate the plug and receptacle shall be 10 pounds. The maximum force required to separate the plug and receptacle shall be five pounds. The rate of travel shall be one inch per minute.

Solvent Resistance Immersion Connectors shall be subjected to the following fluids at the temperature and length of time specified. Following the fluid dip or immersion, the connectors shall be immersed to a depth of 2 to 12 inches in a 5% salt-water solution for 24 hours at room temperature. At the completion of the salt-water immersion test, while still immersed, the connectors shall meet the insulation resistance requirement specified herein.

Fluid Method Temperature No. 2 Diesel Fluid Immersion (2) 140°F Methyl Alcohol Dip (1) Room Temperature Antifreeze - Preston Immersion (2) 180° - 50% Water/50% Immersion (2) 180° Ethylene Glycol Degreaser - Gunk Dip (1) Room Temperature - Mineral Spirits Dip (1) Room Temperature Paints (Oil Base) Immersion (2) Room Temperature Lubricating Oil Immersion (2) 200°F (SAE 10 W40) Brake Fluid Dip (1) Room Temperature (Delco Supreme) Transmission Fluid Dip (1) Room Temperature Fully Submerges and Pressurized @ 7 psi. (Dextron) (1) Dip: Connectors shall withstand a one second dip and a three minute air dry for a total of 80 cycles. (2) Immersion: Connectors shall withstand immersion for one hour. Temperature Life Connectors shall be subjected to a temperature of 150°C ± 3°C for a period of 1000 hours. At the end of the temperature soak period and after removal from the chamber, the connectors shall meet the insulation resistance and dielectric withstanding voltage requirements specified herein. Connectors shall be operated at rated current throughout the duration of the temperature life test. Upon removal from the chamber at the conclusion of the test, the connectors shall show no visual signs of damage, which may be detrimental to the performance of the connector.

Thermal Cycle Connectors shall be subjected to 100 thermal cycles from -40°C to +150°C. One cycle shall consist of the transitions from room temperature to -40°C to +150°C, and from 150°C to room temperature. One cycle shall be accomplished in a three-hour period with a minimum stabilization period of 15 minutes at each temperature extreme. The chamber temperature transition rate shall be a minimum of 1.30°C per minute and a maximum of 6.00°C per minute.

NOTE: Specifications and dimensions subject to change. |

|

ITT CANNON SLC SERIES APPLICATIONS

|

|

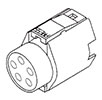

ITT CANNON SLC SERIES SELECT PART NUMBER

Receptacles # of Circuits (Mating view of plug) Plugs Snap Crimp++ PCB

SLC10R500

SLC10B500

Note: A 13 Amp version using large contacts is available for most styles. |

|

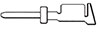

ITT CANNON SLC SERIES CONTACTS & TOOLING

Pins for Receptacles Sockets for Plugs

Wire Sealing Range Wire Hole Filler Extraction Tool

030-2464-007 110238-0446 030-2480-000 110238-0488 112108-0007 Automatic/Semi-

(5.33 - 5.99mm)

(2.42 - 3.30mm) 225-0093-000 274-7068-001 All dimensions are shown in inches (millimeters in parentheses) |

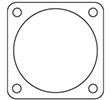

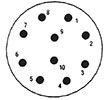

PLUGITT CANNON SLC SERIES PLUG, IN-LINE (TYPE P)

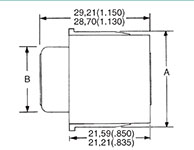

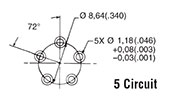

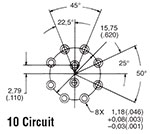

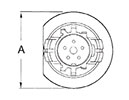

Front-Face View 5 Cavity Housing Side View Plug Assembly Front Face View 10 Cavity Housing Housing SIze Rating Part Number Description A B 5 5 Amp 098532-0011 SLC5P500 27.81 (1.095) 18.03 (.710) 10 5 Amp 098532-0002 SLC10P500 34.92 (1.375) 25.15 (.990) All dimensions shown in millimeters (inches in parentheses) R & B RECEPTACLESITT CANNON SLC SERIES RECEPTACLE, IN-LINE (TYPE R & B)

• For square flange see below.

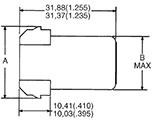

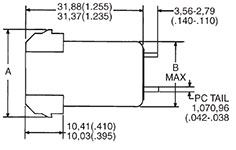

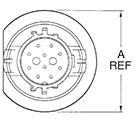

Side View Receptacle Assembly Side View In-line Receptacle with PCB Contacts Front-Face View 5 Cavity Housing Front-Face View 10 Cavity Housing Recommended PC Board Layout:

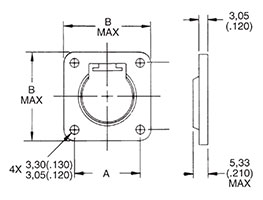

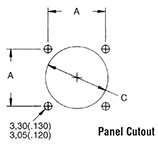

Crimp PCB Housing Size Part Number Description Part Number Description A B C Ref. 5 098530-0000 SLC-5R5-00 098531-0000 SLC-5B5-00 24.13 (.950) 18.03 (.710) 24.38 (.960) 10 098530-0002 SLC-10R5-00 098531-0002 SLC-10B5-00 31.24 (1.230) 25.15 (.990) 31.62 (1.245) Square Flange for R and B type Connectors (shown above)

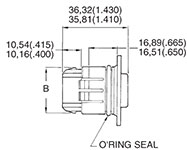

Material: Thermoplastic Color: Black Housing Part Number A B Max. C 5 066-9504-000 23.37 31.24 32.50 - 31.75 10 066-9504-001 28.45 36.32 25.40 - 26.64 All dimensions shown in millimeters (inches in parentheses) SNAP-THRU RECEPTACLEITT CANNON SLC SERIES SNAP-THRU RECEPTACLE (TYPE T)

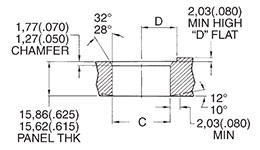

Side View Front-Face View 5 Position Front-Face View 10 Position Panel Section View Housing Size Part Number Description A B C D 5 098533-0000 SLC-5T5-00 37.21 (1.465) 24.13 (.950) 25.60 (1.008) 15.62 (.615) 10 098533-0002 SLC-10T5-00 47.62 (1.875) 31.24 (1.230) 35.05 (1.380) 20.19 (.795) All dimensions shown in millimeters (inches in parentheses) |

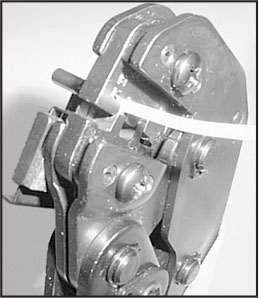

CRIMPINGITT CANNON SLC SERIES CRIMPING

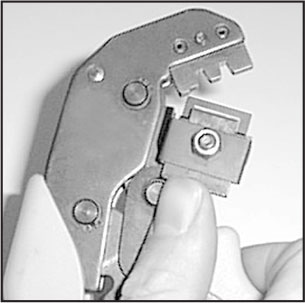

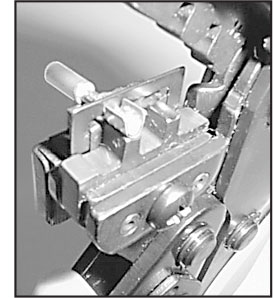

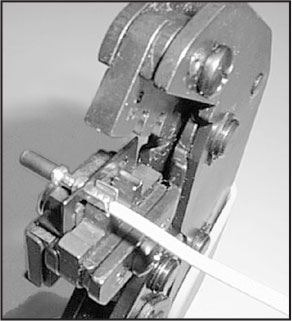

STEP 1: Squeeze handles until tool has gone through a complete cycle and opens easily. STEP 2: Select the proper cavity for the wire size to be crimped. STEP 3: Using your thumb or forefinger, raise the spring-loaded locator on the back of the lower jaw by pushing up. STEP 4: While the locator is in the up position, place the contact into the front of the crimp tool (crimp side up) in the proper crimp cavity (16 AWG or 20 AWG)

STEP 5: Release the locator. The locator should rest comfortably in the indent in the contact just above the crimp area. STEP 6: Insert the stripped wire into the crimp area until it bottoms. STEP 7: Firmly squeeze the handle; crimp jaw and ratchet will release. STEP 8: Using your thumb or forefinger, raise the springloaded locator and remove the crimped contact and wire. INSERTIONITT CANNON SLC SERIES INSERTION

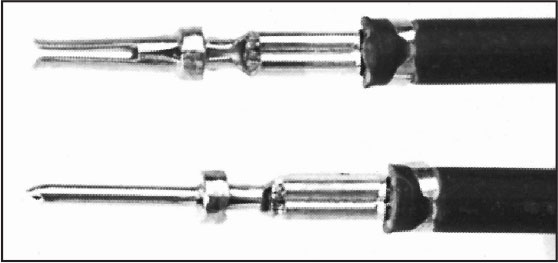

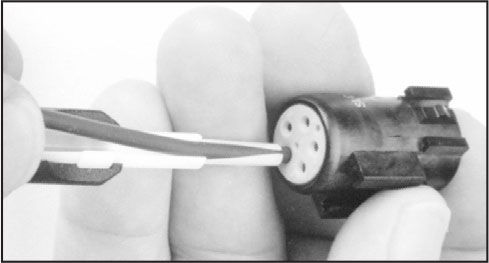

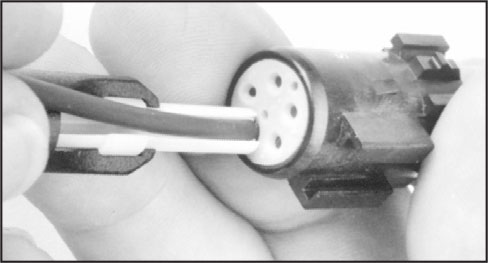

STEP 1: Move to the rear of the connector so that the contact cavities can be identified. STEP 2: Insert a crimp-terminated assembly into a selected cavity. STEP 3: Continue the forward movement until an audible snap can be felt and heard. A slight pull in the opposite direction will confirm complete insertion. CRIMP INSPECTIONITT CANNON SLC SERIES CRIMP INSPECTION

Note that there are no unterminated wire strands and that some strand ends can be seen at the forward edge of the crimp. Also note the insulation is gripped by the smaller secondary crimp. Distortion is at a minimum, both axially and laterally – no sharp edges. Enlargement of micro section allows for final judgment of crimp quality. This test is recommended whenever new tools or new types of wire are used. EXTRACTIONITT CANNON SLC SERIES EXTRACTION

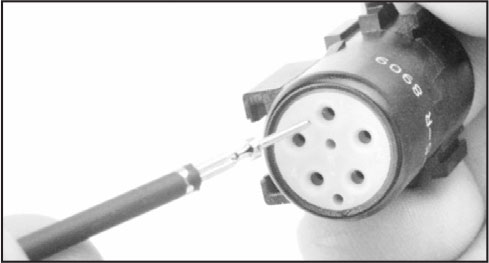

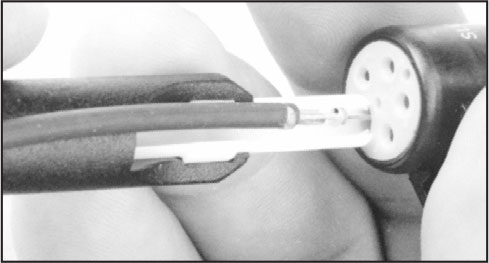

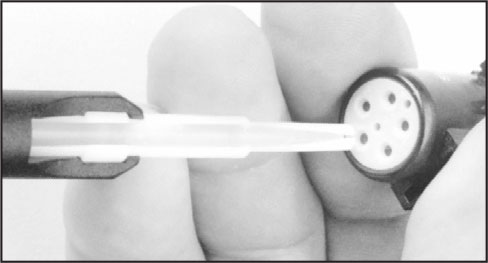

STEP 1: Open the CET – SLC extraction tool and place it over the insulation of the wire. STEP 2: Using a straight motion forward, insert the tool along the wire until it bottoms against the connector. Do not use a screwing motion - damage will result. STEP 3: While the CET - SLC is bottomed, simply pull the wire/contact assembly out. STEP 4: Remove the CET - SLC. Extraction is complete. |

Philadelphia

19116

Click here for the contact information of the branch nearest you.