ITT Cannon SLE Series Snap Lock Connectors

HARSH-ENVIRONMENT SNAP LOCK CONNECTORS

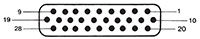

The ITT Cannon Snap Lock Environmental series (SLE) is an environmentally sealed, rectangular connector created for printed circuit board (PCB), cable-to-cable or bulkhead applications. SLE snap lock connectors are suitable for demanding under-the-hood applications and are easy to assemble with an audible and tactile feedback. Snap lock connectors will handle up to 5 amps continuous at a temperature range of -40°C to +125°C. SLE snap lock connectors are available as a 19 or 28 pin connector. For full details on ITT Cannon SLE Snap Lock connectors, see the product specifications below.

|

FEATURESITT CANNON SLE SERIES FEATURES

MATERIALS & FINISHESITT CANNON SLE SERIES MATERIALS & FINISHES

Shell High-performance thermoplastic body, silicone wire seals

Contacts Copper Alloy

Plating Selective gold over nickel plating on mating surface, tin/lead over nickel plating on wire crimp area

ELECTRICAL DATAITT CANNON SLE SERIES ELECTRICAL DATA

Dielectric Withstanding Voltage 1000 Vac rms at sea level

Current Rating 5 Amps continuous at 125ºC

Wire Range Sizes 20 - 16 AWG

Contact Resistance 10 milliohms maximum

Insulation Resistance 20 megohms minimum (USCAR)

MECHANICALITT CANNON SLE SERIES MECHANICAL

Operating Temperature -40°C to 125°C (-40°F to 257°F)

Sealing 2 - 12 inches of 5% salt solution for 24 hours

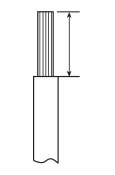

Wire Sealing Range .095” - .120” (2.42mm - 3.05mm)

Insulation Strip Length .210” - .220” (5.33mm - 5.59mm)

Mating Life 25 cycles minimum

Salt Spray 5% solution 96 hours

Heat 125°C +/- 3° 1000 hours

Chemical Resistance Resistant to most common automotive contaminants

Vibration 10.2 grms 20 hours minimum

Shock 100 g’s 18 shocks for 6 milliseconds

Contact Type Crimp using automatic, semi-automatic or hand tooling, printed circuit

Number of Circuits 19 & 28

Contact Insertion From rear, with no insertion tool needed

Contact Removal From rear, with low cost hand tool

Contact Retention 25 lbs. (111N) minimum

Polarization Moveable molded keys and keyways

|

|

ITT CANNON SLE SERIES APPLICATIONS

|

|

SLEB19ITT CANNON SLE SERIES SLEB19 SAMPLE PART NUMBER SLEB19P4SG = 130408-0010 ITT CANNON SLE SERIES SLEB19 CREATE PART NUMBER STEP 1: Pick # of contacts SLEB19 or SLEC28 (19 contacts/28 contacts) Follow steps 2-4 to create order # STEP 2 STEP 3 STEP 4 Connector Style: Cable Entry Style: Mounting Hardware: Convert to Order # P4 S * 130408-0000 P4 S G 130408-0010 P4 L * 130408-0001 P4 R * 130408-0002 P4 U * 130408-0003 P4 U G 130408-0011 P4 D * 130408-0004 P4 U G 130408-0012 Mates With S2 S * 130409-0001 S2 S F 130409-0000 S2 L * 130409-0002 S2 R * 130409-0003 S2 U * 130409-0004 S2 D * 130409-0005 T3 P * 130411-0000 T3 P M 130411-0001 T3 P N 130411-0002 T3 P E 130411-0015 N3 P * 130410-0000 N3 P M 130410-0001 N3 P N 130410-0002 N3 P E 130410-0015 For High-Volume, Low-Temperature (100ºC) Low Cost Tin Lead contacts, please contact us. SLEC28ITT CANNON SLE SERIES SLEC28 SAMPLE PART NUMBER SLEC28P4UG = 130412-0011 ITT CANNON SLE SERIES SLEC28 CREATE PART NUMBER STEP 1: Pick # of contacts SLEB19 or SLEC28 (19 contacts/28 contacts) Follow steps 2-4 to create order # STEP 2 STEP 3 STEP 4 Connector Style: Cable Entry Style: Mounting Hardware: Convert to Order # P4 S * 130412-0000 P4 S G 130412-0010 P4 L * 130412-0001 P4 R * 130412-0002 P4 U * 130412-0003 P4 U G 130412-0011 P4 D * 130412-0004 P4 U G 130412-0012 Mates With S2 S * 130409-0001 S2 S F 130413-0000 S2 L * 130413-0002 S2 R * 130413-0003 S2 U * 130413-0004 S2 D * 130413-0005 T3 P * 130415-0000 T3 P M 130415-0001 T3 P N 130415-0002 T3 P E 130415-0004 N3 P * 130414-0000 N3 P M 130414-0001 N3 P N 130414-0002 N3 P E 130414-0020 For High-Volume, Low-Temperature (100ºC) Low Cost Tin Lead contacts, please contact us. |

|

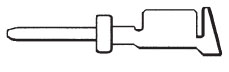

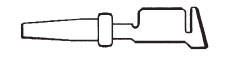

ITT CANNON SLE SERIES CONTACTS & TOOLING

Wire Sealing Range Wire Hole Filler Extraction Tool

030-2464-007 110238-0446 030-2480-007 110238-0488 112108-0007 Automatic/

(5.33 - 5.99 mm)

(2.42 - 3.30 mm) 225-0093-000 274-7068-001 |

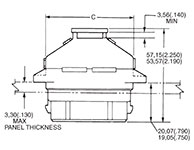

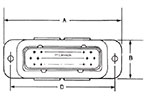

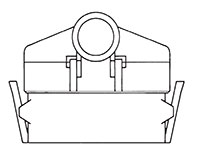

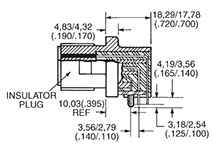

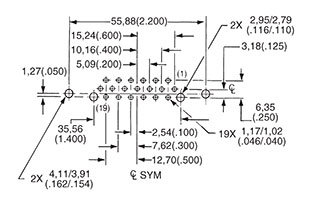

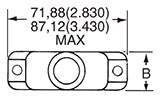

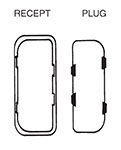

S2 PLUGITT CANNON SLE SERIES S2 PLUG WITH FLANGE ENDBELL (PLUG ONLY)

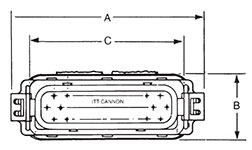

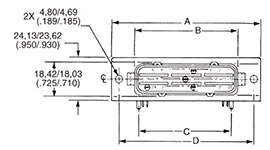

Number of Part Number by A Max. B Max. C Max. D ± 0.38 (.015) 19 SLEB 71.88 (2.830) 26.16 (1.030) 47.50 (1.870) 59.05 (2.325) 28 SLEC 87.11 (3.430) 26.16 (1.030) 62.74 (2.470) 74.29 (2.925) All dimensions shown in millimeters (inches in parentheses) P4 RECEPTACLEITT CANNON SLE SERIES P4 RECEPTACLE

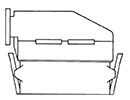

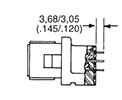

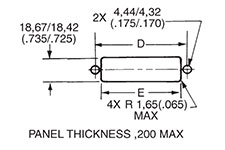

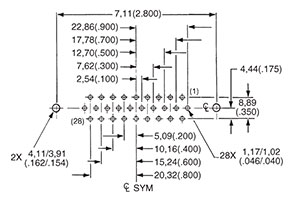

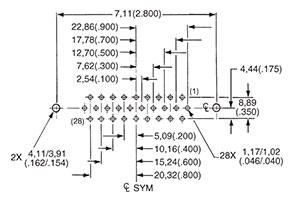

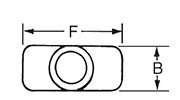

Number of Part Number by Shell Size A Max. B Max. C Max. D Max. E ± 0.38 (.015) F Max. 19 SLEB 59.44 (2.340) 26.16 (1.030) 44.07 (1.735) 50.58 (2.000) 55.87 (2.200) 64.25 (2.530) 28 SLEC 76.45 (3.010) 26.16 (1.030) 59.31 (2.335) 66.04 (2.600) 71.11 (2.800) 79.49 (3.130) All dimensions shown in millimeters (inches in parentheses) PCB PLUGITT CANNON SLE SERIES PRINTED CIRCUIT BOARD PLUG

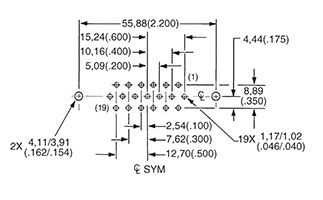

T3 Straight N3 Right Angle

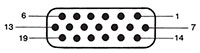

Number of Contacts Part Number by Shell Size A Max. B Max. C Max. D ± .38 (.015) E Max. 19 SLEB 64.25 (2.530) 44.07 (1.735) 35.81 (1.410) 55.87 (2.200) 47.62 (1.875) 28 SLEC 79.49 (3.130) 59.31 (2.335) 51.05 (2.010) 71.11 (2.800) 62.86 (2.475) 19 Contacts 19 Contacts All dimensions shown in millimeters (inches in parentheses) CONTACT ARRANGEMENTITT CANNON SLE SERIES CONTACT ARRANGEMENT

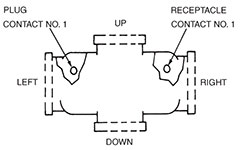

Face View - Engaging Face of Plug

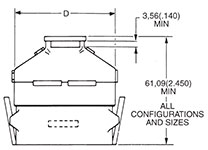

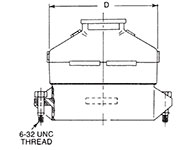

ENDBELLSENDBELLS

Part Number by Shell Size B Max. F Max. Cable Entry I.D. SLEB 26.16 (1.030) 50.80 (2.000) 14.73 (.580) SLEC 26.16 (1.030) 66.04 (2.600) 19.81 (.780) All dimensions shown in millimeters (inches in parentheses) |

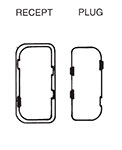

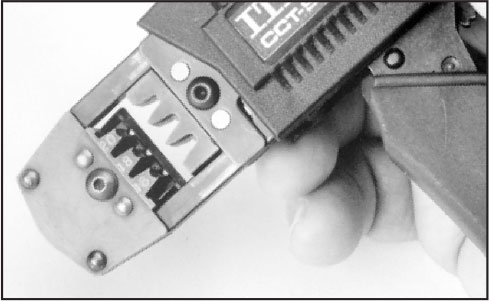

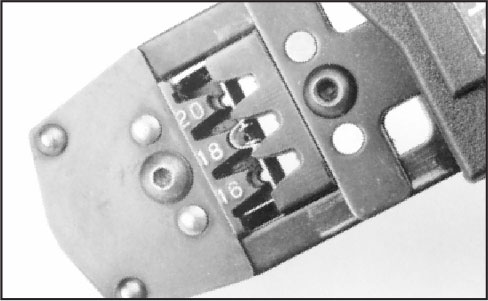

CRIMPINGITT CANNON SLE SERIES CRIMPING

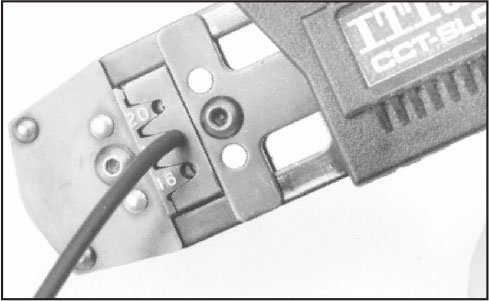

STEP 1: Cycle the CCT-SLE hand tool to the open position. Hand tool Part No. 995-0002-232 STEP 2: While pressing upward on the locator spring, insert the contact with tails upward completely into the locator. STEP 3: When correctly positioned, the contact should be located beyond flush with the edge of the CCT-SLE and be positioned on the concave, polished split level crimp.

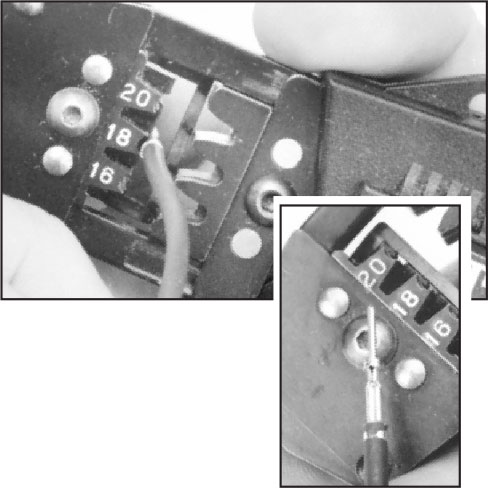

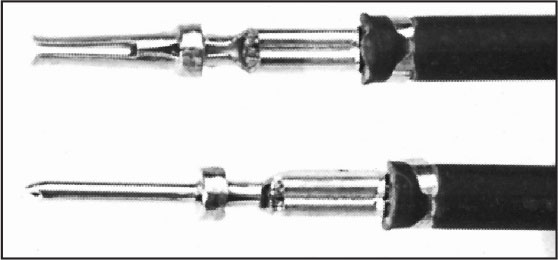

STEP 4: Partially cycle (usually the first click) the hand tool, assuring that the upward-thrusting tails of the contact have started engaging with the top jaw of the tool. There is a slight tendency for the contact to roll out of vertical alignment. STEP 5: Insert the pre-stripped wire into the crimp area of the contact and completely cycle the tool. STEP 6: While pressing upward on the locator spring, withdraw the crimp termination. The result will be a perfect termination. CRIMP INSPECTIONITT CANNON SLE SERIES CRIMP INSPECTION

Note that there are no un-terminated wire strands and that some strand ends can be seen at the forward edge of the crimp. Also note the insulation is gripped by the smaller secondary crimp. Distortion is at a minimum, both axially and laterally – no sharp edges. Enlargement of micro section allows for final judgment of crimp quality. This test is recommended whenever new tools or new types of wire are used. INSERTIONITT CANNON SLE SERIES INSERTION

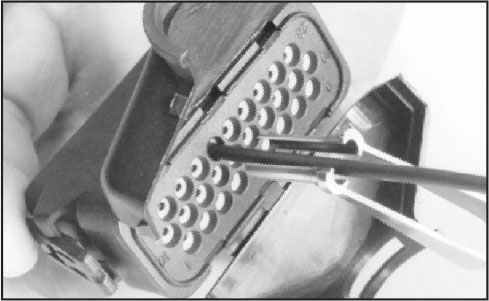

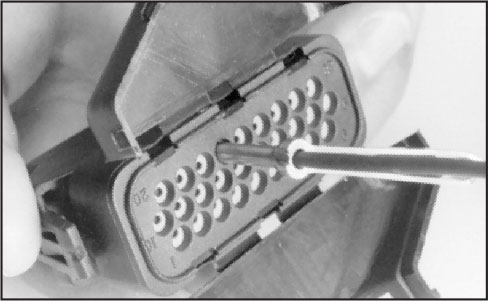

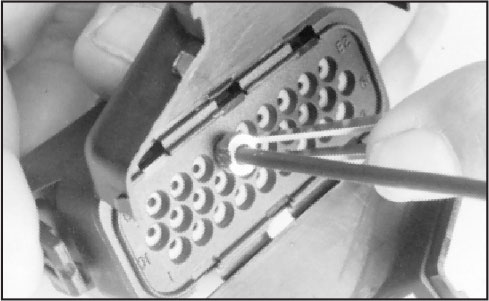

Insert contact from rear; an audible snap can be felt and heard. A slight pull in the opposite direction will confirm complete insertion. EXTRACTIONITT CANNON SLE SERIES EXTRACTION (SLE SHOWN)

STEP 1: Open the CET-SLE extraction tool and place it over the insulation of the wire. STEP 2: Using a straight, forward motion, insert the tool along the wire until it bottoms against the connector. Do not use a screwing motion as damage will result. STEP 3: While the CET-SLE is bottomed, simply pull the wire/contract assembly out. STEP 4: Remove the CET-SLE. Extraction is complete. |

Philadelphia

19116

Click here for the contact information of the branch nearest you.