ITT Cannon High Temp Micro-D Connectors

RUGGED MICRO-D FOR USE IN EXTREME TEMPERATURES

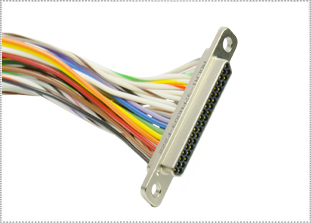

With the increasing demand for compact, ruggedized interconnect solutions that can withstand temperatures up to 200° C, ITT’s Cannon brand continues to lead the industry with high reliability products customized for applications from satellites to down hole analyzers. The High Temperature Micro-D connector series has been engineered with a strong yet lightweight aluminum shell and micro twist pin contact system. With an increased operating temperature up to +200° C (+392°F) ITT Cannon’s High Temp Micro-D connector series is ideal for the harsh environments of space, down hole drilling and missile systems. Part numbers begin M83513; ITT Cannon part numbers begin MDM. For full details on ITT Cannon High Temp MDM series Micro-D 83513-Style connectors, please see product specifications below.

Learn more about these Micro-D connectors by checking out our blog post called: "Durable Downhole Connectors for Rugged Conditions".

|

FEATURESITT CANNON HIGH TEMP MICRO-D SERIES FEATURES

MATERIALS & FINISHESITT CANNON HIGH TEMP MICRO-D SERIES MATERIALS & FINISHES

Shell Aluminum alloy per QQ-A-200/8 (6061-T6)

Plating Yellow chromate over cadmium per QQ-P-416, Type II, Class 3 over electroless nickel underplate or for Zero cadmium and space applications, electroless nickel per MIL-C-26074, Class 3 of 4, Grade B

Contacts Pins - outer strands BeCu alloy per QQ-C-530

Inner strands - copper alloy per QQ-W-343, Type S Sleeve - copper alloy per ASTM B75 Sockets - copper alloy per ASTM B140 Plating Minimum 50 microinches gold per MIL-G-45204, Type II, Grade C, Class 1, over copper flash

Insulator Liquid Crystal Polymer (LCP) A130 or C130 color black per MIL-M-24519, Type GLCP-30

Epoxy Wire Seal Pre-wired harnesses - Hysol EE4215/HD3561 (black)

Printed circuit - Hysol MG8F-0134 (black) Wire 25 AWG Solid copper per QQ-W-343, Type S, Plated Tin 100 microinches or gold 10 microinches MDM - 26 AWG Teflon wire 7/34 per MIL-W-16878/4, Type E Yellow or Color Coded per MIL-STD-681 System 1 M83513 - 26 AWG Teflon wire 19/38 per MIL-W-22759 White or Color Coded per MIL-STD-681 System 1 except wire number equals contact cavity number minus 1, and 10 colors repeating

ELECTRICAL DATAITT CANNON HIGH TEMP MICRO-D SERIES ELECTRICAL DATA

Test Voltage 600 Vac at sea level

150 Vac at 70,000 feet (23410 meters) Current Rating 3 Amps

Contact Resistance 8 milliohms maximum at 3 amps

10 milliohms maximum at 1 milliamps: MIL-STD-202 Method 307 Insulation Resistance 5000 megohms minimum at 500 Vdc

1000 megohms minimum after condition; MIL-STD-1344 Method 1002 Magnetic Permeability 2.0μ (connectors less hardware)

Thermal Vacuum Outgassing per NASA SP-R-0022 (space class only)

Printed circuit - Hysol MG8F-0134 (black) Total Mass Loss 1.0 percent maximum

Volatile Condensable Material (VCM) 0.1 percent maximum MECHANICALITT CANNON HIGH TEMP MICRO-D SERIES MECHANICAL

Operating Temperature -55ºC to +200ºC (-67ºF to +392ºF)

Sealing Humidity

Mating Life 500 cycles minimum

Salt Spray 48 hours MIL-STD-1344 Method 1001 Condition B

Chemical Resistance Cleaning solvents: Perchloroethylene US practical grade, 2 hours Lubricating oil aircraft turbine engine, synthetic base 20 hours Coolant (coolanol 25 or equivalent) 1 hour +/- 1 minute

Vibration 20g’s MIL-STD-1344 Method 2005 Condition IV

Shock 50g’s MIL-STD-1344 Method 2004 Condition C

Contact Type Pre-wired, solder, printed circuit board (gold-plated)

Number of Circuits 9 to 100

Contact Retention 5 pounds minimum

Polarization D-shaped shells

Approvals MIL-DTL-83513

|

|

ITT CANNON HIGH TEMP MICRO-D SERIES APPLICATIONS

|

|

STEP 1: MATERIALITT CANNON HIGH TEMP MICRO-D SERIES PART NUMBER EXAMPLE

1 2 3 4 5 6 MDM - - - - -F222 SHELL STYLE LAYOUT CONTACT TERMINATIONS HARDWARE MOD CODE STEP 1: CHOOSE INSERT MATERIAL TYPE

MDM OR RMDM (RoHS)

Liquid Crystal Polymer* *Note: Previous Material was Diallyl Phthalate or Polyester STEP 4: TERMINATIONSTEP 4: CHOOSE TERMINATION

BS = Straight Printed BR = Right Angle S = Solder Cup 26

CBR = Narrow Profile Wire Terminations** Code Length Inches (mm) L61 .125 (3.18) L56 .150 (3.81) L57 .190 (4.83) L39 .250 (6.35) L58 .375 (9.52) L1 .500 (12.70) L14 .750 (19.05) L2 1.000 (25.40) L7 1.500 (38.11) L6 2.000 (50.80) L16 2.500 (63.50) L10 3.000 (76.20) 16878/4 Standard Wire Terminations** Yellow Color Coded Length Inches (mm) H020 H027 3 (76.2) H019 H016 6 (152.4) H026 H034 8 (203.2) H029 H025 10 (254.0) H028 H002 12 (304.8) H001 H003 18 (457.2) H038 H023 20 (508.0) H009 H004 24 (609.6) H010 H005 30 (762.0) H011 H006 36 (914.4) H013 H048 48 (1219.2) H017 H046 72 (1828.8) H042 H041 120 (3048.0) * Note Previous Material was Diallyl Phthalate or Polyester ** For wire lengths and types other than listed, please contact us. Dimensions are shown in inches (millimeters in parentheses) STEP 5: HARDWARESTEP 5: CHOOSE HARDWARE

T = Threaded; A = Large Through Hole; B = Standard Through Hole; B1 = Through Hole for size 100;

F = Float Mount

P = Jackpost

K = Jackscrew

L = Low Profile Jackscrew M = Click here for more information STEP 6: MOD CODESTEP 6: CHOOSE MOD CODE

A174 = Electroless nickel (RoHS)* F222 = Special high-temperature version A174-F222 * = Special high-temperature version * PCB Tails are not RoHS, PC Tails are tin-lead plated. |

|

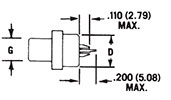

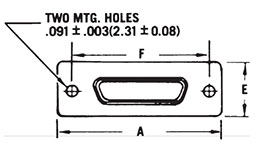

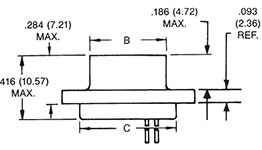

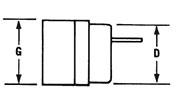

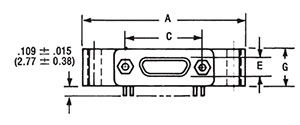

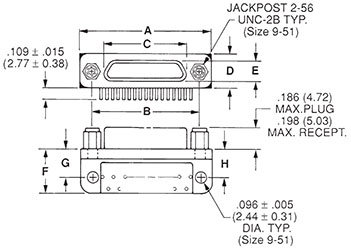

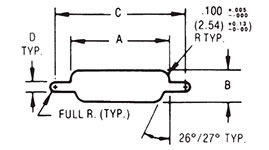

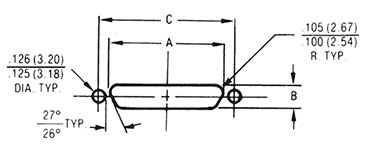

PLUGSITT CANNON HIGH TEMP MICRO-D SERIES PLUG DIMENSIONS (CONFORMS TO MIL-DTL-83513)

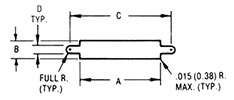

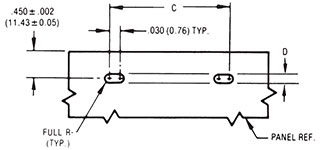

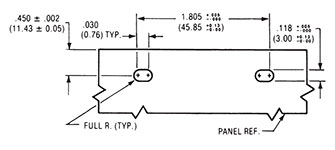

Part Number by A Max. B Max. C Max. D Max. E Max. F G Max. Average Weights** oz. (gm.) +/-5% MDM-9P* .785 (19.94) .334 (8.48) .400 (10.16) .270 (6.86) .308 (7.82) .565 (14.35) .185 (4.70) .063 (1.79) MDM-15P* .935 (23.75) .484 (12.29) .550 (13.97) .270 (6.86) .308 (7.82) .715 (18.16) .185 (4.70) .084 (2.39) MDM-21P* 1.085 (27.56) .634 (16.10) .700 (17.78) .270 (6.86) .308 (7.82) .865 (21.97) .185 (4.70) .105 (2.99) MDM-25P* 1.185 (30.10) .734 (18.64) .800 (20.32) .270 (6.86) .308 (7.82) .965 (24.51) .185 (4.70) .119 (3.39) MDM-31P* 1.335 (33.91) .884 (22.45) .950 (24.13) .270 (6.86) .308 (7.82) 1.115 (28.32) .185 (4.70) .140 (3.99) MDM-37P* 1.485 (37.72) 1.034 (26.26) 1.100 (27.94) .270 (6.86) .308 (7.82) 1.265 (32.13) .185 (4.70) .161 (4.59) MDM-51P* 1.435 (36.45) .984 (24.99) 1.050 (26.67) .310 (7.87) .351 (8.92) 1.215 (30.86) .228 (5.79) .193 (5.50) MDM-100P* 2.170 (55.12) 1.384 (35.15) 1.442 (36.63) .360 (9.14) .394 (10.01) 1.800 (45.72) .271 (6.88) .500 (14.3) ITT CANNON HIGH TEMP MICRO-D SERIES PANEL MOUNTING DIMENSIONS (SIZES 9-100)

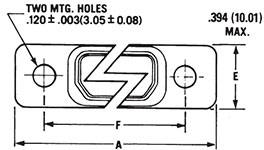

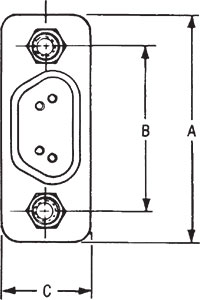

All dimensions are shown in inches (millimeters in parentheses) RECEPTACLESITT CANNON HIGH TEMP MICRO-D SERIES RECEPTACLE STYLES

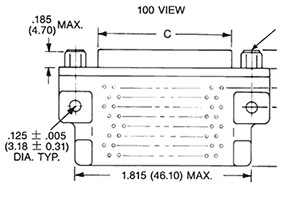

ITT CANNON HIGH TEMP MICRO-D SERIES RECEPTACLE (MDM-100 ONLY)

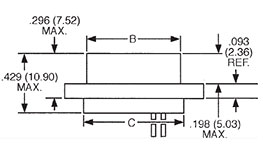

Part Number by A Max. B Max. C Max. D Max. E Max. F G Max. Average Weights** oz. (gm.) +/-5% MDM-9S* .785 (19.94) .402 (10.21) .400 (10.16) .270 (6.86) .308 (7.82) .565 (14.35) .253 (6.43) .063 (1.79) MDM-15S* .935 (23.75) .552 (13.97) .550 (13.97) .270 (6.86) .308 (7.82) .715 (18.16) .253 (6.43) .083 (2.37) MDM-21S* 1.085 (27.56) .702 (17.83) .700 (17.78) .270 (6.86) .308 (7.82) .865 (21.97) .253 (6.43) .104 (2.97) MDM-25S* 1.185 (30.10) .802 (20.37) .800 (20.32) .270 (6.86) .308 (7.82) .965 (24.51) .253 (6.43) .118 (3.36) MDM-31S* 1.335 (33.91) .952 (24.18) .950 (24.13) .270 (6.86) .308 (7.82) 1.115 (28.32) .253 (6.43) .139 (3.96) MDM-37S* 1.485 (37.72) 1.102 (27.99) 1.100 (27.94) .270 (6.86) .308 (7.82) 1.265 (32.13) .253 (6.43) .160 (4.56) MDM-51S* 1.435 (36.45) 1.052 (26.72) 1.050 (26.67) .310 (7.87) .351 (8.92) 1.215 (30.86) .296 (7.52) .188 (5.35) MDM-100S* 2.170 (55.12) 1.508 (38.10) 1.442 (36.63) .360 (9.14) .394 (10.01) 1.800 (45.72) .394 (10.01) 1.040 (29.5) * Add lead type and length; see Create Part Number ** Weight given is 1/2", uninsulated, solid, #25 AWG gold plated copper pigtails All dimensions are shown in inches (millimeters in parentheses) ITT CANNON HIGH TEMP MICRO-D SERIES PANEL MOUNTING DIMENSIONS (SIZES 9-100)

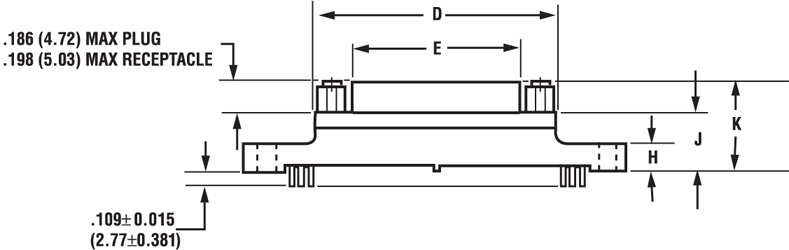

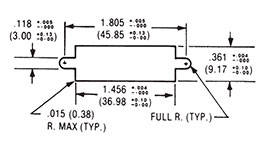

BS SERIESITT CANNON HIGH TEMP MICRO-D SERIES BS (BOARD STRAIGHT) SERIES

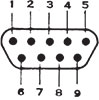

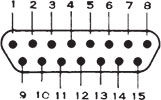

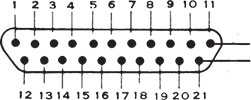

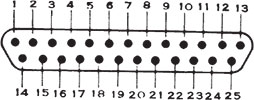

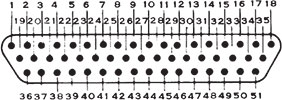

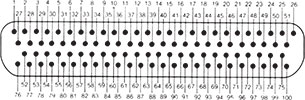

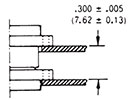

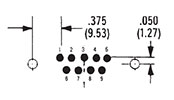

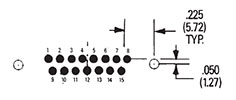

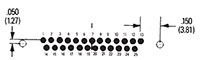

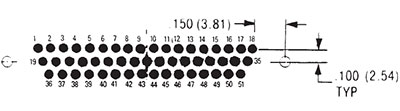

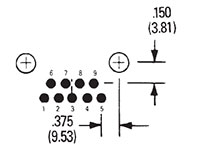

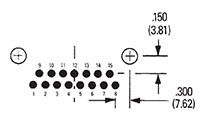

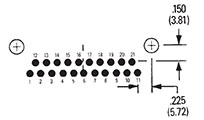

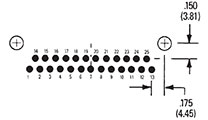

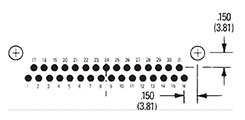

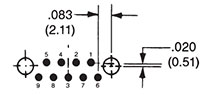

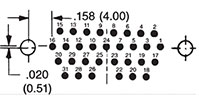

NOTE: Standard lead termination is #24 AWG, solid copper, solder or tin dipped. Part # by Shell Size A Max. B ± .007 (.018) C ± .005 (.013) D Max. E Max. F ± .005 (0.13) G Max. H Max. J Max. K Max. MDM-9PBS* 1.390 (35.31) 1.150 (29.21) .565 (14.35) .785 (19.94) .334 (8.48) .185 (4.70) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-9SBS* 1.390 (35.31) 1.150 (29.21) .565 (14.35) .785 (19.94) .402 (10.21) .253 (6.43) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-15PBS* 1.390 (35.31) 1.150 (29.21) .715 (18.16) .935 (23.75) .484 (12.29) .185 (4.70) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-15SBS* 1.390 (35.31) 1.150 (29.21) .715 (18.16) .935 (23.75) .552 (13.97) .253 (6.43) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-21PBS* 1.690 (43.93) 1.450 (36.83) .865 (21.97) 1.085 (27.56) .634 (16.10) .185 (4.70) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-21SBS* 1.690 (43.93) 1.450 (36.83) .865 (21.97) 1.085 (27.56) .702 (17.83) .253 (6.43) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-25PBS* 1.740 (44.20) 1.500 (38.10) .965 (24.51) 1.185 (30.10) .734 (18.64) .185 (4.70) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-25SBS* 1.740 (44.20) 1.500 (38.10) .964 (24.51) 1.185 (30.10) .802 (20.37) .253 (6.43) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-31PBS* 2.040 (51.82) 1.800 (45.72) 1.115 (28.32) 1.335 (33.91) .884 (22.45) .185 (4.70) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-31SBS* 2.040 (51.82) 1.800 (45.72) 1.115 (28.32) 1.335 (33.91) .952 (24.18) .253 (6.43) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-37PBS* 2.340 (59.44) 2.100 (53.34) 1.265 (32.13) 1.485 (37.72) 1.034 (26.26) .185 (4.70) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-37SBS* 2.340 (59.44) 2.100 (53.34) 1.265 (32.13) 1.485 (37.72) 1.102 (27.99) .253 (6.43) .308 (7.82) .165 (4.19) .355 (9.02) .555 (14.10) MDM-51PBS* 2.270 (67.66) 2.000 (50.80) 1.215 (30.86) 1.435 (36.45) .984 (24.99) .228 (5.79) .351 (8.92) .165 (4.19) .355 (9.02) .555 (14.10) MDM-51SBS* 2.270 (67.66) 2.000 (50.80) 1.215 (30.86) 1.435 (36.45) 1.052 (26.72) .296 (7.52) .351 (8.92) .165 (4.19) .355 (9.02) .555 (14.10) MDM-100PBS* 3.070 (77.98) 2.800 (71.12) 1.800 (45.72) 2.175 (55.24) 1.384 (35.15) .271 (6.88) .460 (11.68) .303 (7.70) .550 (12.70) .686 (17.42) MDM-100SBS* 3.070 (77.98) 2.800 (71.12) 1.800 (45.72) 2.175 (55.24) 1.508 (38.30) .394 (10.01) .460 (11.68) .303 (7.70) .550 (12.70) .686 (17.42) * For jackpost, add letter "P" or "M7" for sizes 9-51, "M17" for size 100 All dimensions are shown in inches (millimeters in parentheses) Dimensions are subject to change ITT CANNON HIGH TEMP MICRO-D SERIES BS (BOARD STRAIGHT) PIN TERMINATION ARRANGEMENTS View PCB Solder Side

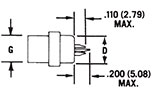

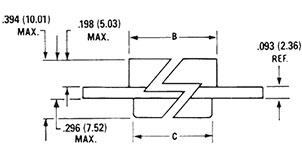

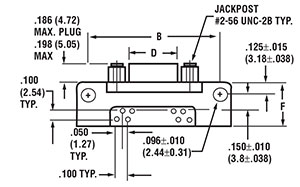

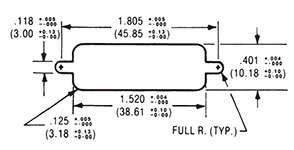

BR SERIESITT CANNON HIGH TEMP MICRO-D SERIES BR (BOARD RIGHT ANGLE) SERIES

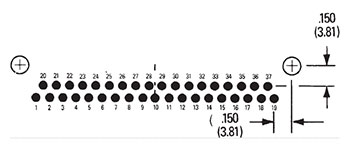

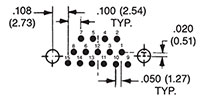

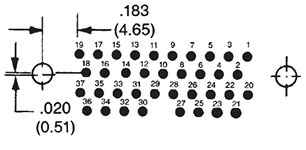

NOTE: Standard lead termination is #24 AWG, solid copper, solder or tin dipped. Part # by A Max. B ± .007 (.018) C ± .005 (.013) D Max. E Max. F Max. G Max. MDM-9PBR* 1.390 (35.31) 1.150 (29.21) .565 (14.35) .334 (8.48) .185 (4.70) .455 (11.56) .308 (7.82) MDM-9SBR* 1.390 (35.31) 1.150 (29.21) .565 (14.35) .402 (10.21) .253 (6.43) .455 (11.56) .308 (7.82) MDM-15PBR* 1.540 (39.12) 1.300 (33.02) .715 (18.16) .484 (12.29) .185 (4.70) .455 (11.56) .308 (7.82) MDM-15SBR* 1.540 (39.12) 1.300 (33.02) .715 (18.16) .552 (13.97) .253 (6.43) .455 (11.56) .308 (7.82) MDM-21PBR* 1.690 (42.93) 1.450 (36.83) .865 (21.97) .634 (16.10) .185 (4.70) .455 (11.56) .308 (7.82) MDM-21SBR* 1.690 (42.93) 1.450 (36.83) .865 (21.97) .702 (17.83) .253 (6.43) .455 (11.56) .308 (7.82) MDM-25PBR* 1.790 (45.47) 1.550 (39.37) .965 (24.51) .734 (18.64) .185 (4.70) .455 (11.56) .308 (7.82) MDM-25SBR* 1.790 (45.47) 1.550 (39.37) .965 (24.51) .802 (20.37) .253 (6.43) .455 (11.56) .308 (7.82) MDM-31PBR* 2.040 (51.82) 1.800 (45.72) 1.115 (28.32) .884 (22.45) .185 (4.70) .455 (11.56) .308 (7.82) MDM-31SBR* 2.040 (51.82) 1.800 (45.72) 1.115 (28.32) .952 (24.18) .253 (6.43) .455 (11.56) .308 (7.82) MDM-37PBR* 2.340 (59.44) 2.100 (53.34) 1.265 (32.13) 1.034 (26.26) .185 (4.70) .455 (11.56) .308 (7.82) MDM-37SBR* 2.340 (59.44) 2.100 (53.34) 1.265 (32.13) 1.102 (27.99) .253 (6.43) .455 (11.56) .308 (7.82) MDM-51PBR* 1.875 (47.63) 1.600 (40.64) 1.215 (30.86) .984 (24.99) .228 (7.52) .565 (14.35) .351 (8.92) MDM-51SBR* 1.875 (47.63) 1.600 (40.64) 1.215 (30.86) 1.052 (26.72) .296 (7.52) .565 (14.35) .351 (8.92) *For jackpost, add letter "P" or "M7" for sizes 9-51, "M17" for size 100. All dimensions are shown in inches (millimeters in parentheses) Dimensions are subject to change ITT CANNON HIGH TEMP MICRO-D SERIES BR (BOARD RIGHT ANGLE) PIN TERMINATION ARRANGEMENTS

CBR SERIESITT CANNON HIGH TEMP MICRO-D SERIES CBR (CONDENSED BOARD RIGHT ANGLE) SERIES

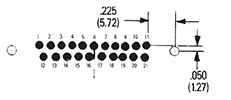

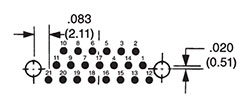

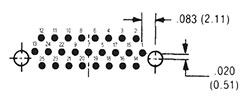

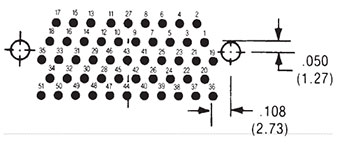

NOTE: Standard lead termination is #24 AWG, solid copper, solder or tin dipped. Part # by Shell Size A Max. B ± .005 (.013) C Max. D Max. E Max. F Max. G ± .010 (.025) H ± .010 (.025) MDM-9PCBR* .785 .565 .334 .308 .185 .420 .250 .230 MDM-9SCBR* .785 .565 .402 .308 .253 .420 .250 .230 MDM-15PCBR* .935 .715 .484 .308 .185 .420 .250 .130 MDM-15SCBR* .935 .715 .552 .308 .253 .420 .250 .130 MDM-21PCBR* 1.085 .865 .634 .308 .185 .420 .250 .130 MDM-21SCBR* 1.085 .865 .702 .308 .253 .420 .250 .130 MDM-25PCBR* 1.185 .965 .734 .308 .185 .420 .250 .130 MDM-25SCBR* 1.185 .965 .802 .308 .253 .420 .250 .130 MDM-31PCBR* 1.335 1.115 .884 .308 .185 .520 .250 .130 MDM-31SCBR* 1.335 1.115 .952 .308 .253 .520 .250 .130 MDM-37PCBR* 1.485 1.265 1.034 .308 .185 .520 .250 .130 MDM-37SCBR* 1.485 1.265 1.102 .308 .253 .520 .250 .130 MDM-51PCBR* 1.435 1.215 .984 .351 .228 .650 .300 .150 MDM-51SCBR* 1.435 1.215 1.052 .351 .296 .650 .300 .150 MDM-100PCBR* 2.170 1.800 1.384 .394 .271 1.000 .400 .200 MDM-100SCBR* 2.170 1.800 1.508 .394 .394 1.000 .400 .200 *For jackpost, add letter "P" or "M7" for sizes 9-51, "M17" for size 100. All dimensions are shown in inches (millimeters in parentheses) Dimensions are subject to change ITT CANNON HIGH TEMP MICRO-D SERIES CBR (CONDENSED BOARD RIGHT ANGLE) PIN TERMINATION ARRANGEMENTS View PCB Solder Side

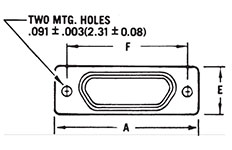

PANEL CUTOUTSITT CANNON HIGH TEMP MICRO-D SERIES PANEL CUTOUTS - SHELL SIZES 9-51 Figure 1 Front Mounting Figure 2 Rear Mounting Figure 3 Edgeboard Mounting

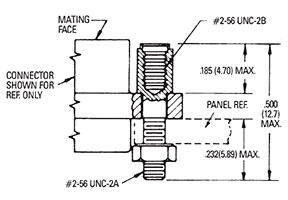

NOTES: 1. Front mounting (Figure 1) and rear mounting (Figure 2) accomodates #2-56 screws. 2. Front mounting is preferred. However, when rear mounting is necessary, use figure 2 dimensions when jackscrews are used. Shell Cutout A + .004 (0.10) - B + .004 (0.10) - C + .005 (0.13) - D + .005 (0.13) - 9 1 .408 (10.36) .271 (6.88) .570 (14.48) .089 (2.26) 9 2 .401 (10.19) .252 (6.40) .570 (14.48) .089 (2.26) 9 3 - - .570 (14.48) .089 (2.26) 15 1 .558 (14.17) .271 (6.88) .720 (18.29) .089 (2.26) 15 2 .551 (14.00) .252 (6.40) .720 (18.29) .089 (2.26) 15 3 - - .720 (18.29) .089 (2.26) 21 1 .708 (17.98) .271 (6.88) .870 (22.10) .089 (2.26) 21 2 .701 (17.81) .252 (6.40) .870 (22.10) .089 (2.26) 21 3 - - .870 (22.10) .089 (2.26) 25 1 .808 (20.52) .271 (6.88) .970 (24.64) .089 (2.26) 25 2 .801 (20.34) .252 (6.40) .970 (24.64) .089 (2.26) 25 3 - - .970 (24.64) .089 (2.26) 31 1 .958 (24.33) .271 (6.88) 1.120 (28.45) .089 (2.26) 31 2 .951 (24.16) .252 (6.40) 1.120 (28.45) .089 (2.26) 31 3 - - 1.120 (28.45) .089 (2.26) 37 1 1.108 (28.14) .271 (6.88) 1.270 (32.26) .089 (2.26) 37 2 1.101 (27.97) .252 (6.40) 1.270 (32.26) .089 (2.26) 37 3 - - 1.270 (32.26) .089 (2.26) 51 1 1.508 (26.87) .315 (8.00) 1.220 (30.99) .089 (2.26) 51 2 1.051 (26.70) .295 (7.49) 1.220 (30.99) .089 (2.26) 51 3 - - 1.220 (30.99) .089 (2.26) ITT CANNON HIGH TEMP MICRO-D SERIES SHELL SIZE 100 Figure 5 Front Mounting Figure 6 Rear Mounting Edgeboard Mounting

NOTES: 1. Front mounting (FIgure 5) and rear mounting (Figure 6) accommodates #4-40 screws. 2. Front mounting is preferred. However, when rear mounting is necessary, use Figure 6 dimensions. All dimensions are shown in inches (millimeters in parentheses) |

|

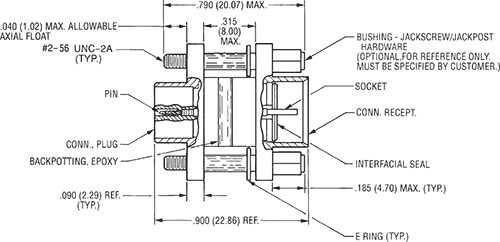

CONNECTOR SAVERITT CANNON HIGH TEMP MICRO-D SERIES CONNECTOR SAVER Save wear and tear on your equipment and system connectors by using the "Connector Saver." The multi-matings and unmatings experienced by most connectors during testing and final check out can be eliminated. Simply mate the Connector Saver to your unit and use the opposite side for your testing interface... less wear, less tear, less chance of damage. It is available in all eight standard MDM layouts. Mating hardware is available and can be ordered either separately or included with the Connector Saver. Typical MDM style connections have a minimum mating cycle life of 500 matings. By using up to 500 Connector Savers, equipment mating life can be extended 500 times. 500 mates x 500 Connector Savers = 250,000 matings before you would need to replace/repair the original connector on the piece of equipment.

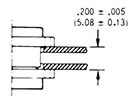

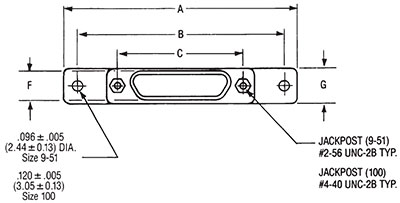

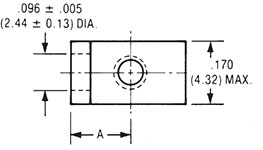

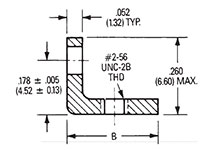

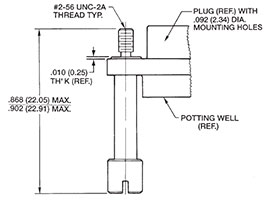

A174 Electroless Nickel Size With Hardware W/O Hardware *Hardware Kits A Max. B ±.005 (0.13) C Max. 9 MDM98479-86 MDM98479-18 320-9505-014** .785 (19.94) .565 (14.35) .308 (7.82) 15 MDM98479-87 MDM98479-19 320-9505-014** .935 (23.75) .715 (18.16) .308 (7.82) 21 MDM98479-88 MDM98479-20 320-9505-014** 1.085 (27.56) .865 (21.97) .308 (7.82) 25 MDM98479-89 MDM98479-21 320-9505-014** 1.185 (30.10) .965 (24.51) .308 (7.82) 31 MDM98479-90 MDM98479-14 320-9505-014** 1.335 (33.91) 1.115 (28.32) .308 (7.82) 37 MDM98479-91 MDM98479-15 320-9505-014** 1.485 (37.72) 1.265 (32.13) .308 (7.82) 51 MDM98479-92 MDM98479-16 320-9505-014** 1.435 (36.45) 1.215 (30.86) .351 (8.91) 100 MDM98479-93 MDM98479-17 320-9508-014*** 2.170 (55.12) 1.800 (45.72) .394 (10.01) * Kit contains 2 bushings-jackpost/jackscrew and 2 E-rings. ** Size 9-51 - #2-56 UNC-2B Thread *** Size 100 - #4-40 UNC-2B Thread All dimensions are shown in inches (millimeters in parentheses) JACKPOST BUSHINGITT CANNON HIGH TEMP MICRO-D SERIES JACKPOST BUSHING (FOR REAR PANEL MOUNTING FOR SIZES 9-51)

Jackpost Kit Number* Panel Thickness 320-9505-007 3/32 (2.4) 320-9505-006 1/16 (1.6) 320-9505-005 3/64 (1.2) 320-9505-004 1/32 (0.8) * A kit consists of 2 jackposts, 2 nuts, 2 washers ITT CANNON HIGH TEMP MICRO-D SERIES PLUG & RECEPTACLE PANEL CUTOUT DIMENSIONS

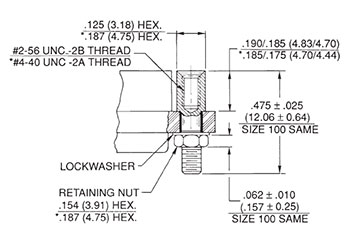

Shell Size A +.004 (0.10) .000 (0.00) B +.004 (0.10) .000 (0.00) C ± .005 (0.13) 9 .401 (10.19) .252 (6.40) .565 (14.35) 15 .551 (14.00) .252 (6.40) .715 (18.16) 21 .701 (17.81) .252 (6.40) .865 (21.97) 25 .801 (20.34) .252 (6.40) .965 (24.51) 31 .951 (24.16) .252 (6.40) 1.115 (28.34) 37 1.101 (27.97) .252 (6.40) 1.265 (32.13) 51 1.051 (26.70) .295 (7.49) 1.215 (30.86) Dimensions are shown in inches (millimeters in parentheses) MOUNTING HARDWAREITT CANNON HIGH TEMP MICRO-D SERIES MOUNTING HARDWARE VIEWS (FOR SIZES 9-51) This hardware is factory-installed.

Part Number Description A ± .005 (±0.13) B Max. 322-9500-000 Screw Lock Assemby N/A 320-9505-000 Jackpost Kit N/A 015-9516-002 Mounting Bracket 90º MDM for 9 through 37 Shell Sizes .147 (3.73) .308 (7.82) 015-9516-003 Mounting Bracket 90º MDM for 51 Shell Sizes .169 (4.29) .350 (8.89) NOTES: Screw lock assembly (322-9500-000) can be used for front mounting only. Jackpost kit (320-9505-000) consists of two assemblies, shipped unassembled.

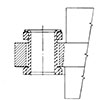

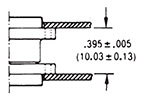

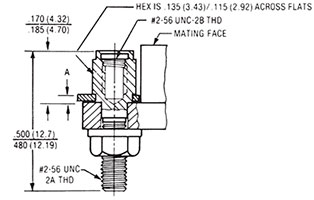

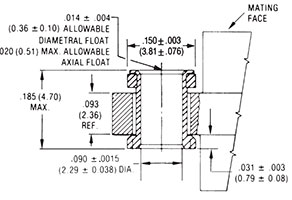

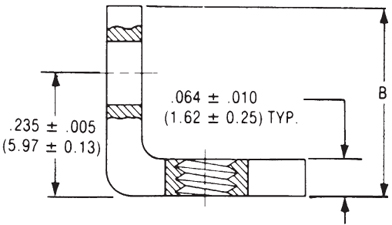

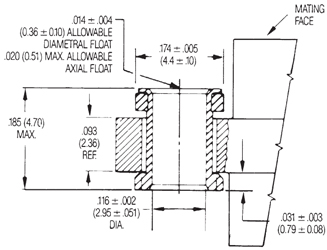

Shown here is a cutaway view of the float mount for the MDM connector. The basic shell dimensions are the same for the float mount and the screw mounting hole configurations. View shown is for standard float mount front panel mounting. Reverse mounting is available on request. ITT CANNON HIGH TEMP MICRO-D SERIES MOUNTING HARDWARE TO MILITARY SPECIFICATIONS (FOR SIZES 9-100) PER MIL-DTL-83513/05

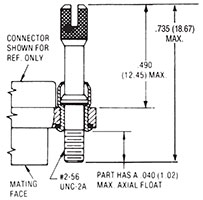

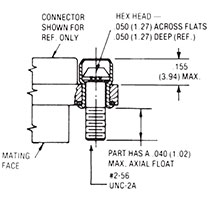

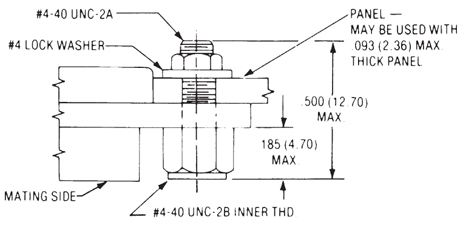

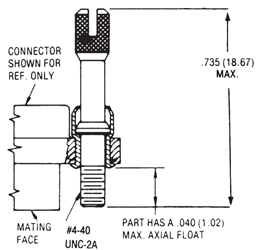

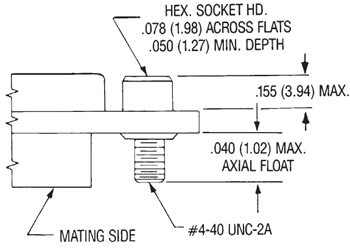

Figure 1. Figure 2. Figure 3. Allen Head To order hardware kits separately, order either by M83513/05-** or by 320-950X-XXX. Size 9-51 Size 100 Description Mod Code Part Number Mil # Mod Code Part Number Mil # Slotted Head Jackscrew Assy Low Profile (Figure 1) M5 320-9508-025 M83513/05-05 M15 320-9508-021 M83513/05-15 Slotted Head Jackscrew Assy High Profile (Figure 2) M6 320-9508-027 M83513/05-06 M16 320-9508-023 M83513/05-16 Allen Had Jackscrew Assy Low Profile (Figure 1) M2 320-9508-026 M83513/05-02 M12 320-9508-022 M83513/05-12 Allen Had Jackscrew Assy High Profile (Figure 2) M3 320-9508-028 M83513/05-03 M13 320-9508-024 M83513/05-13 Jackpost Assy (Figure 3) M7 320-9508-033 M83513/05-07 M17 320-9508-030 M83513/05-17 *Size 100 requires B1 size mounting holes ITT CANNON HIGH TEMP MICRO-D SERIES MOUNTING HARDWARE VIEWS FOR SIZE 100

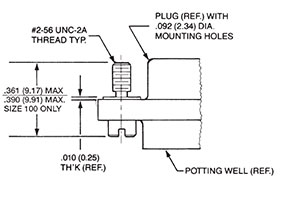

This hardware is supplied unassembled. 320-9505-015 015-9528-000

ITT CANNON HIGH TEMP MICRO-D SERIES PRE-INSTALLED HARDWARE

This hardware is factory-installed.

*Note: Torque values are as follows: Low Profile Jackscrew (L)-4.0 in/lbs. Standard Jackscrew (K)-4.0 in/lbs. ITT CANNON HIGH TEMP MICRO-D SERIES JACKPOST BUSHING FOR REAR PANEL MOUNTING

Jackpost Kit Number* Panel Thickness 320-9505-013 3/32 (2.4) 320-9505-012 1/16 (1.6) 320-9505-010 1/32 (0.8) 320-9505-011 3/64 (1.2) Dimensions for Rear Panel Mountings Dimensions are shown in inches (millimeters in parentheses) |

Philadelphia

19116

Click here for the contact information of the branch nearest you.